Batting puffing device for spinning

A puffing device and technology of using cotton tires, which are applied in the field of cotton textile processing, can solve the problem of cotton wool sticking to the tooth pressure under the grinding and pressing plate, and achieve the effect of ensuring the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

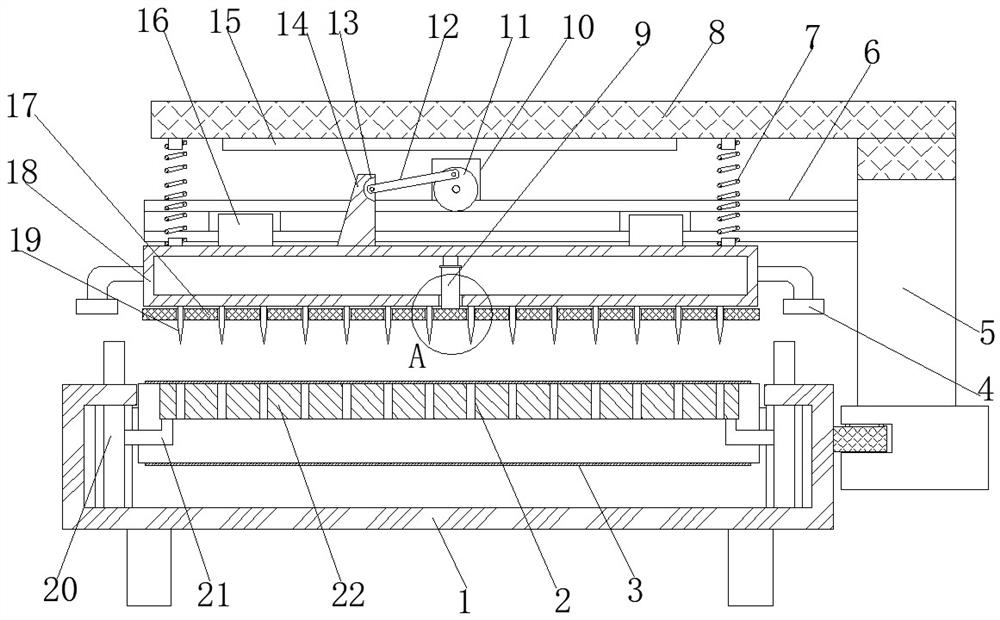

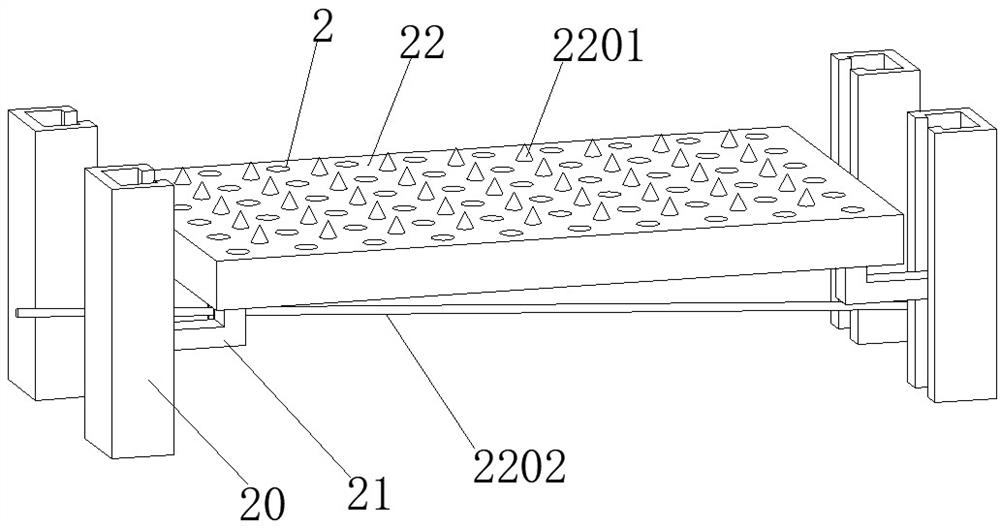

[0028] refer to Figure 1-5 , a cotton batt puffing device for textiles, comprising a base 1 with an upward cross-section having a C-shaped structure, the groove bottom of the base 1 is rotatably connected to both ends of the drive roller 301, and the outer walls of the two drive rollers 301 The same conveying mesh belt 3 is wound between them, and the lower surface near the top conveying mesh belt 3 is provided with a lifting pallet 22, the side of the base 1 is fixed with a slide rail, and a sliding support frame 5 is slidably connected to the slide rail, and the sliding support The two sides of the frame 5 near the top are respectively fixed with C-shaped steel beams 6 with opposite openings. The same pressure plate 18 is slidably connected between the two C-shaped steel beams 6. The pressure plate 18 is a hollow structure, and there is a round hole in the middle of the bottom of the pressure plate 18. , the top inner wall of the pressure plate 18 is fixed with an electric ...

Embodiment 2

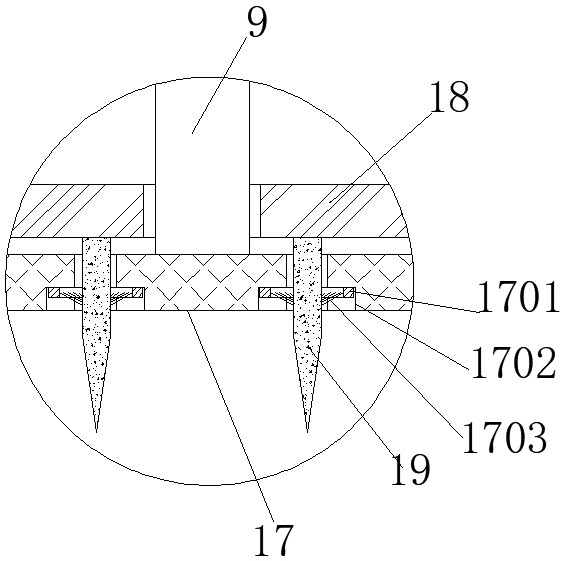

[0038] refer to figure 1 and image 3, a cotton batt bulking device for weaving, compared with Embodiment 1, this embodiment also includes.

[0039] In the present invention, the lower surface of the clamping plate 17 is provided with stepped through holes 1702 equidistantly distributed and adapted to the diameter of the vertebral body 19, and the stepped through holes 1702 are all sleeved with cleaning rings 1701, and the inner walls of the cleaning rings 1701 are provided with Has 1703 bristles.

[0040] When the present invention is in use: the fluff stuck on the vertebral body 19 can be cleaned by controlling the elongation of the electric push rod 9 extension rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com