Integrated silica sand permeable material paving device

A permeable material and integrated technology, applied in the field of integrated silica sand permeable material paving device, can solve the problems of poor integrity, uneven distribution of permeable materials, and inability to effectively achieve uniform distribution, so as to achieve uniform feeding and avoid material paving. The effect of uneven installation and improvement of pavement quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

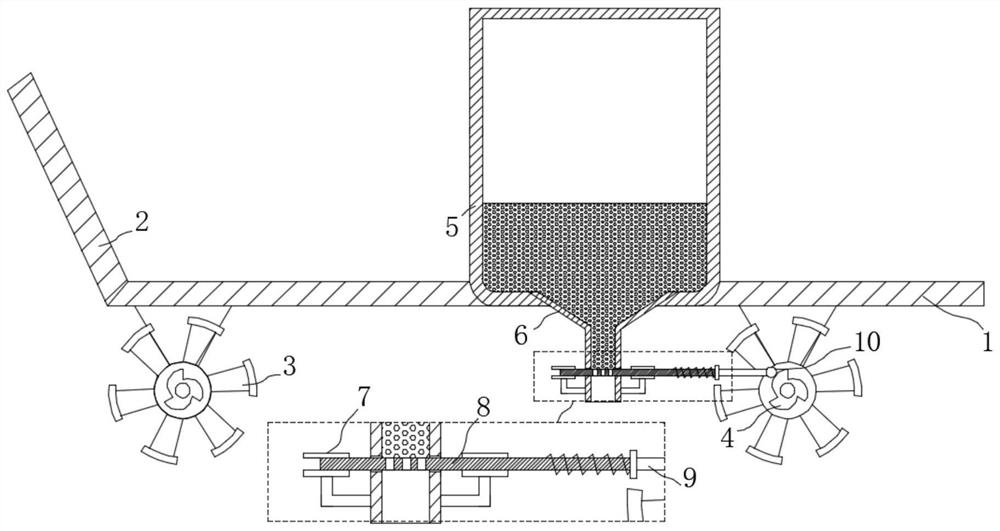

[0025] Example 1: See figure 1 , the present invention provides a technical solution: an integrated silica sand permeable material paving device, including a mobile frame 1, a material storage box 5 and a blanking structure, the rear side of the mobile frame 1 is connected with a push handle 2, Its bottom side end is distributed with mobile wheels 3, and the end of mobile wheels 3 on the front side of mobile frame 1 is connected with multi-lateral cam 4 in a rotational manner; It has a material storage chamber, and the bottom of the material storage box 5 is provided with a discharge pipe 6 protruding from the bottom of the mobile frame 1 and communicating with the storage chamber; the discharge structure is distributed at the discharge pipe 6, and the discharge structure includes a guide slide Cover 7, intermittent blanking plate 8 and push rod 9, guide sliding sleeve 7 are connected to both sides of the bottom of the discharge pipe 6 through brackets; Both ends of the plate...

Embodiment 2

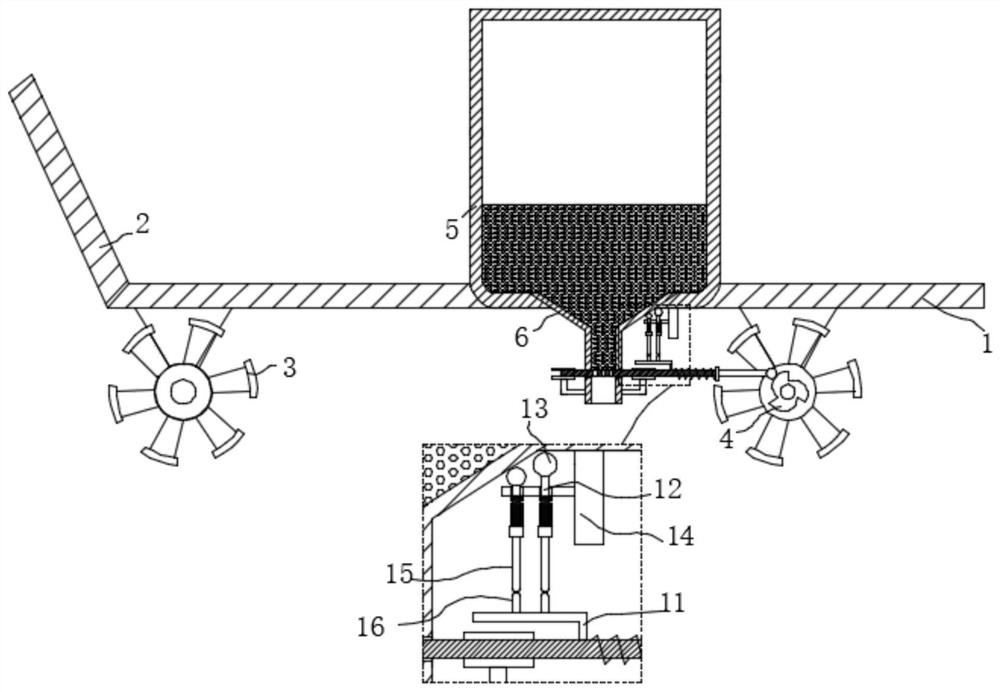

[0027] Example 2: see figure 2 , the outer side of the bottom of the discharge pipe 6 is also equipped with an auxiliary blanking assembly, the auxiliary blanking assembly includes a dial frame 11, a hammer rod 12, a hammer 13 and a mounting plate 14, and the mounting plate 14 is fixed on the mobile frame 1 close to A plurality of sliding holes are distributed on the mounting plate 14 at the bottom end of the discharge pipe 6 , and each sliding hole is provided with a hammer rod 12 that can slide up and down. The top of the hammer rod 12 protrudes from the sliding hole and extends to the top of the mounting plate 14 and is connected with a hammer 13. The bottom of the hammer rod 12 protrudes from the sliding hole and extends to the bottom of the mounting plate 14 and is connected with a connecting block 15. 12 upper cover is provided with spring.

[0028] In this embodiment, the shifting frame 11 is connected to the end of the intermittent blanking plate 8 close to the hamme...

Embodiment 3

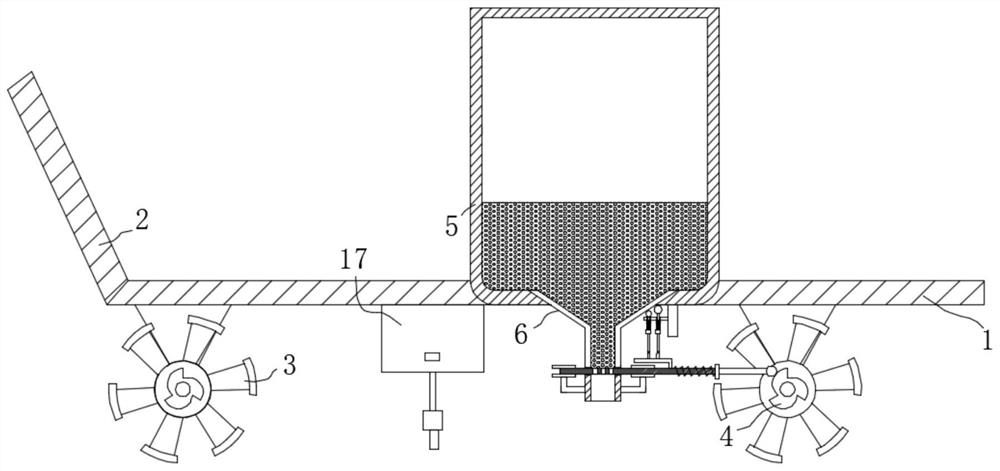

[0030] Example 3: See Figure 3-4 , the above-mentioned paving device also includes a paving and paving structure, which is used to disperse and pave the silica sand material after blanking. The tooth plate 18, the fan-shaped half gear 19 and the dispersed paving assembly, the two shells 17 are fixed on both sides of the bottom of the mobile frame 1, and the bottoms of the two shells 17 are provided with long guiding holes; the movable tooth plate 18 is vertically arranged, The top of the movable tooth plate 18 passes through the top of the housing 17 and is connected with a first stopper, the bottom end of the movable tooth plate 18 passes through the bottom of the housing 17 and is connected with a second stopper, and the movable tooth plate 18 protrudes from the top of the housing 17 And the bottom end is covered with a spring.

[0031] In this embodiment, the sector-shaped half gear 19 is rotatably connected to the inner wall of the housing 17 through a rotating shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com