Shovel loader

A technology of shovel loaders and buckets, which is applied in the field of engineering equipment, can solve the problems of harsh working environment and large exhaust emissions of loaders, achieve the effects of small ventilation requirements, rich and flexible operating functions, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

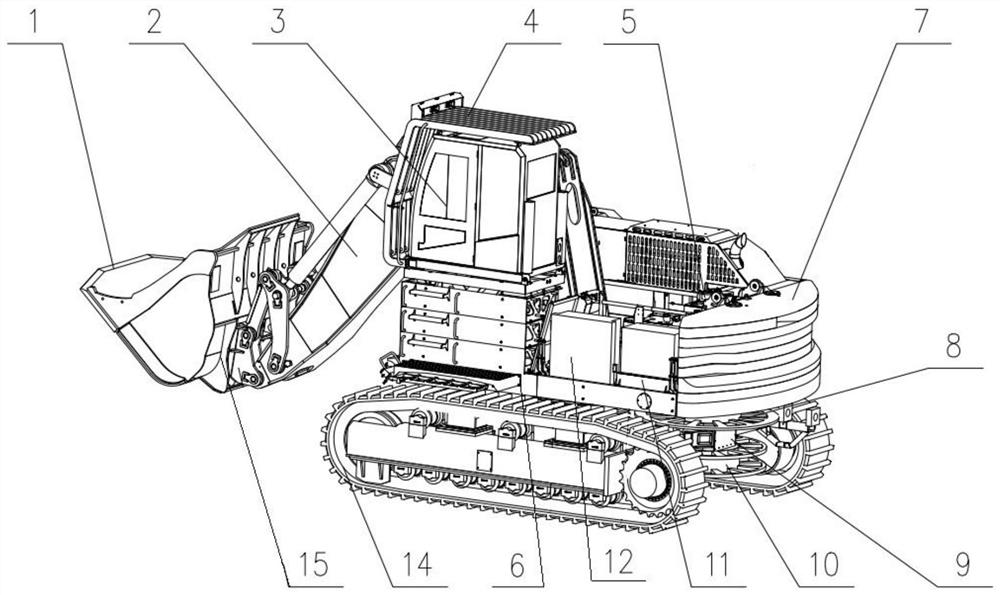

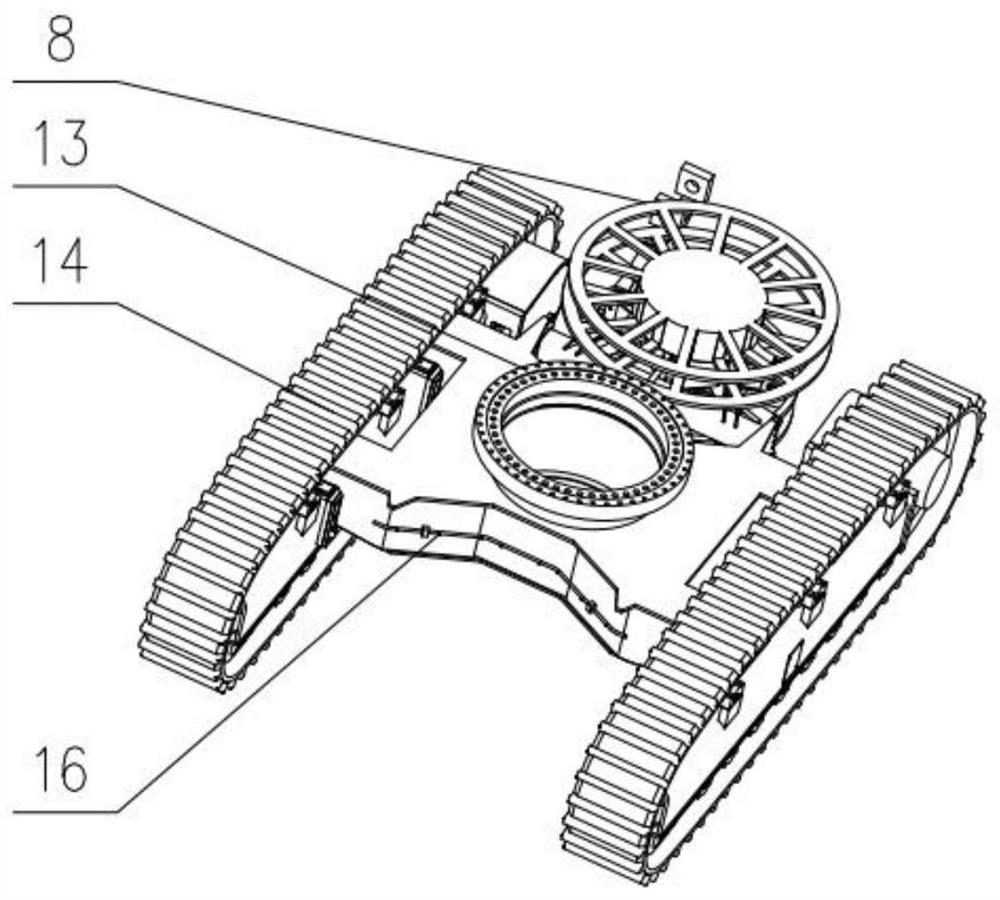

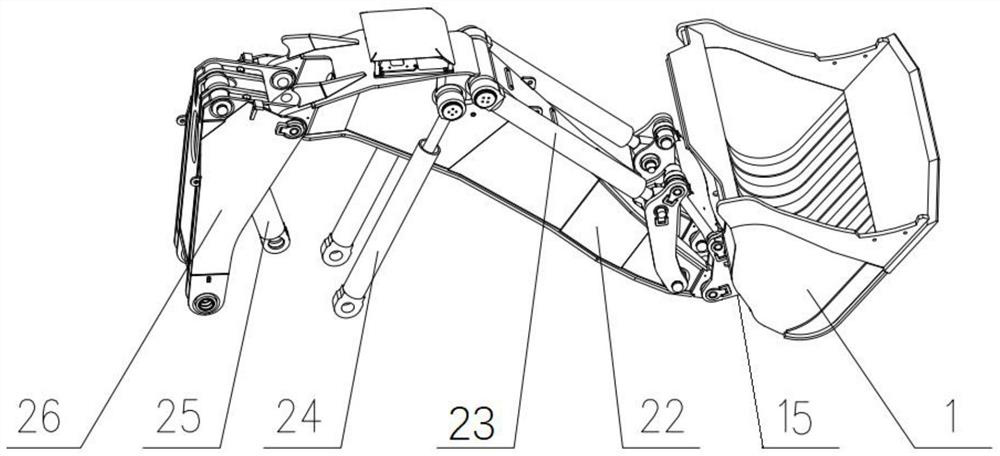

[0025] see Figure 1 to Figure 5 , a shovel loader, comprising a vehicle frame 6, a traveling mechanism 14, a slewing bearing 13, a driver's cab 3, a bucket driving arm 2, a bucket 1, a power system 5 and a dust suppression device 16; The mechanism is used for the walking of the shovel loader. There is a slewing bearing 13 on the walking mechanism, and the slewing bearing is connected to the vehicle frame. The bucket driving arm 2 and the cab 3 are arranged on the vehicle frame. The bucket driving arm 2 is connected to the bucket 1. The slewing bearing drives the frame to rotate 360 degrees, and the cab controls the bucket driving arm and bucket to carry out shoveling operations; the power system is set at the rear end of the frame to provide power for the shovel loader; the walking mechanism is equipped with a dust suppression device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com