Wall surface assembly type veneer abutted seam structure

A veneer, prefabricated technology, used in building construction, covering/lining, construction, etc., can solve the problems of veneer deformation, warpage, etc., and achieve the effect of increasing structural strength, low noise, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

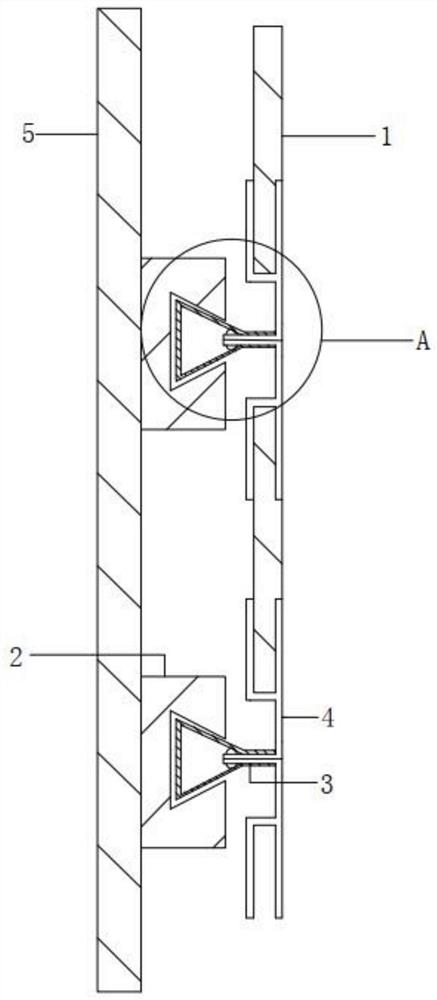

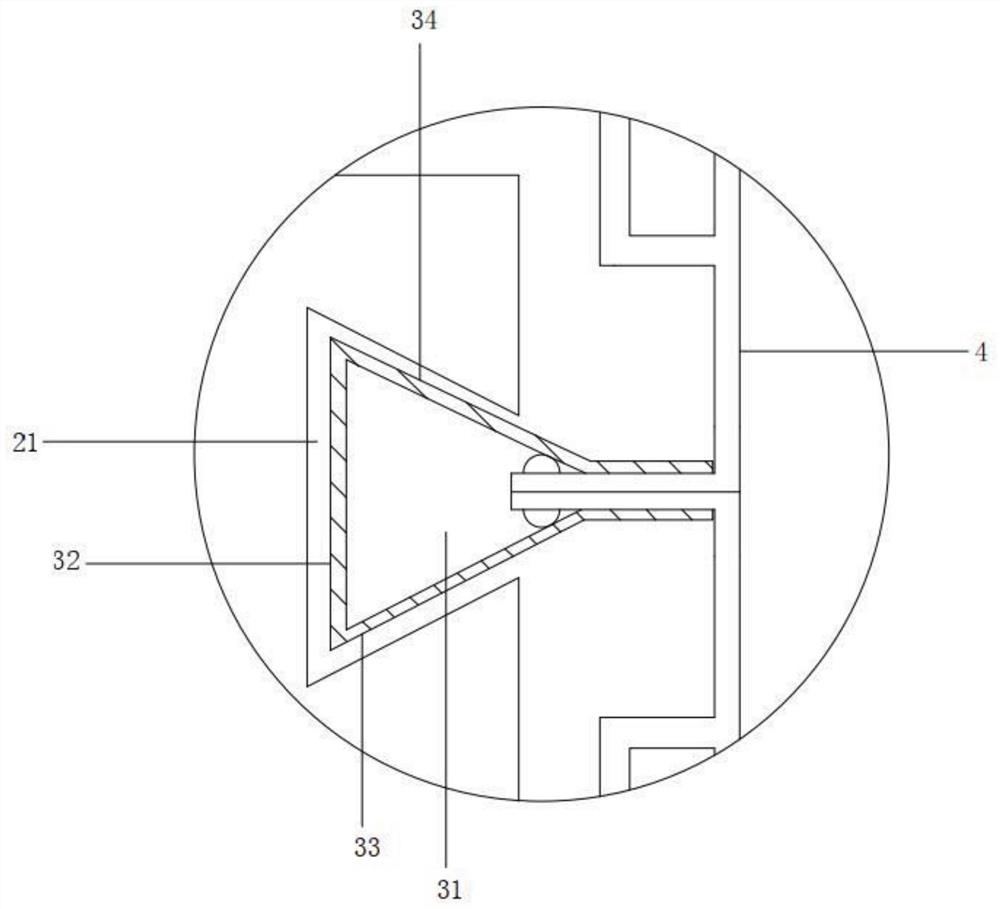

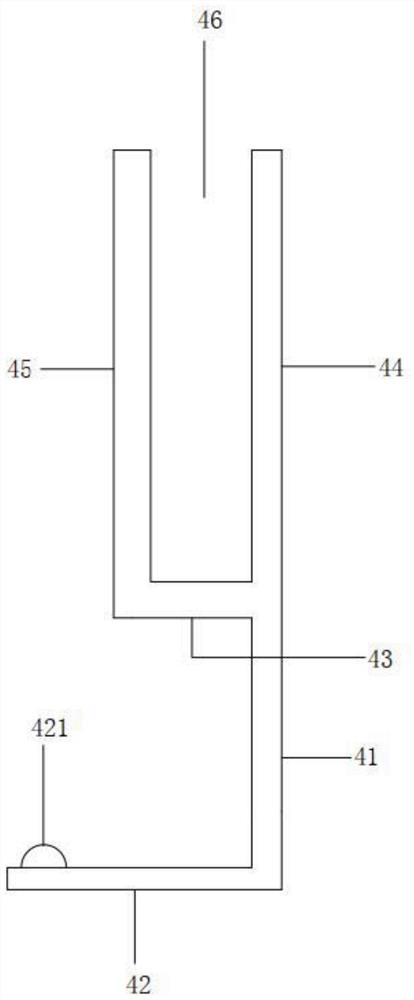

[0029] see Figure 1 to Figure 5 , the figure shows a wall-mounted veneer joint structure provided by Embodiment 1 of the present invention, including a plurality of veneer panels 1, a first connecting piece 2, a second connecting piece 3 and a clamping piece 4, the first A connecting piece 2 is fixedly installed on the wall base 5, the second connecting piece 3 is connected to the first connecting piece 2, and the second connecting piece 3 is provided with a first card slot 31, and the clamping piece 4 includes a clamping part and a The connecting part, the end of the decorative panel 1 is clamped in the clamping part, the connecting part includes a connecting plate 41 and a limiting plate 42, the limiting plate 42 is perpendicular to the connecting plate 41, after the adjacent decorative panels 1 are docked, the two limiting plates 42 are jointed into the first card slot 31 after lamination.

[0030] continue to see Figure 1 to Figure 5 The clamping portion includes a fir...

Embodiment 2

[0040] see Figure 1 to Figure 5 , the figure shows a wall-mounted veneer joint structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first A connecting piece 2 is a light steel keel. The first connecting piece 2 is provided with a second locking groove 21, and the second connecting piece 3 is locked in the second locking groove 21. The cross section of the second locking groove 21 is triangular. Through the setting of the above structure, the quick installation of the second connecting part can be realized, and the width of the second connecting part can be limited to prevent the second connecting part from slipping out of the second slot.

Embodiment 3

[0042] see Figure 1 to Figure 5 , the figure shows a wall-mounted veneer joint structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The second connecting piece 3 is a hanging keel, the second connecting piece 3 includes a first keel plate 32 and a second keel plate 33 and a third keel plate 34 arranged at both ends of the first keel plate 32, the second keel plate 33 and the third keel plate The distance between the keel plates 34 decreases gradually along the direction away from the first keel plate 32 . In this way, the clamping piece can be fixed more stably, preventing the clamping piece from slipping out of the second connecting piece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com