A new energy vehicle electronic control circuit board testing system and testing method

A new energy vehicle, electronic control technology, used in electronic circuit testing, vibration testing, impact testing and other directions, can solve the problem of inappropriate clamping position, single control function of circuit board, inaccurate data analysis, etc., to achieve data error small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

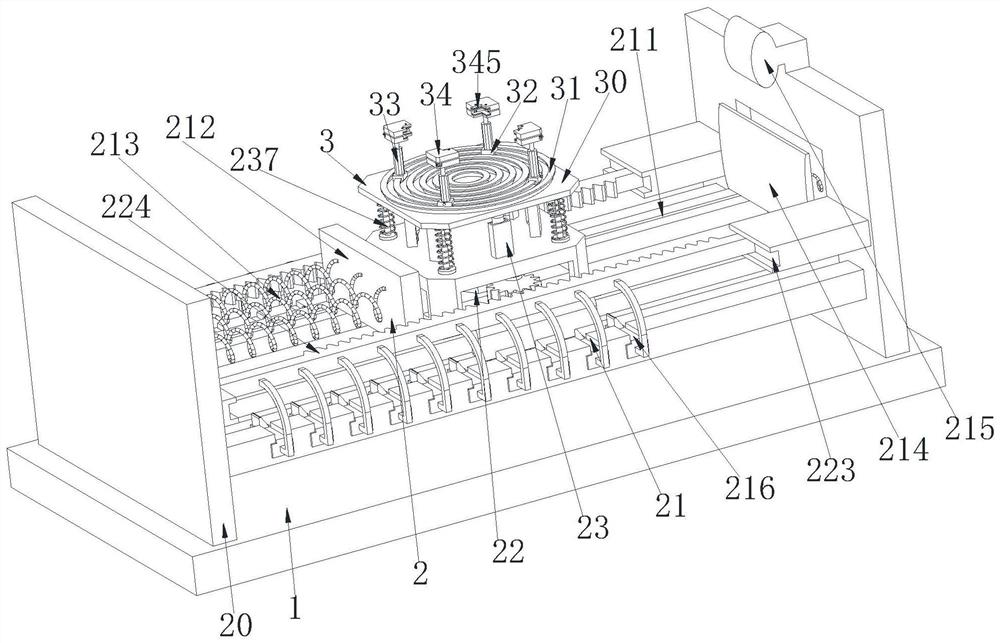

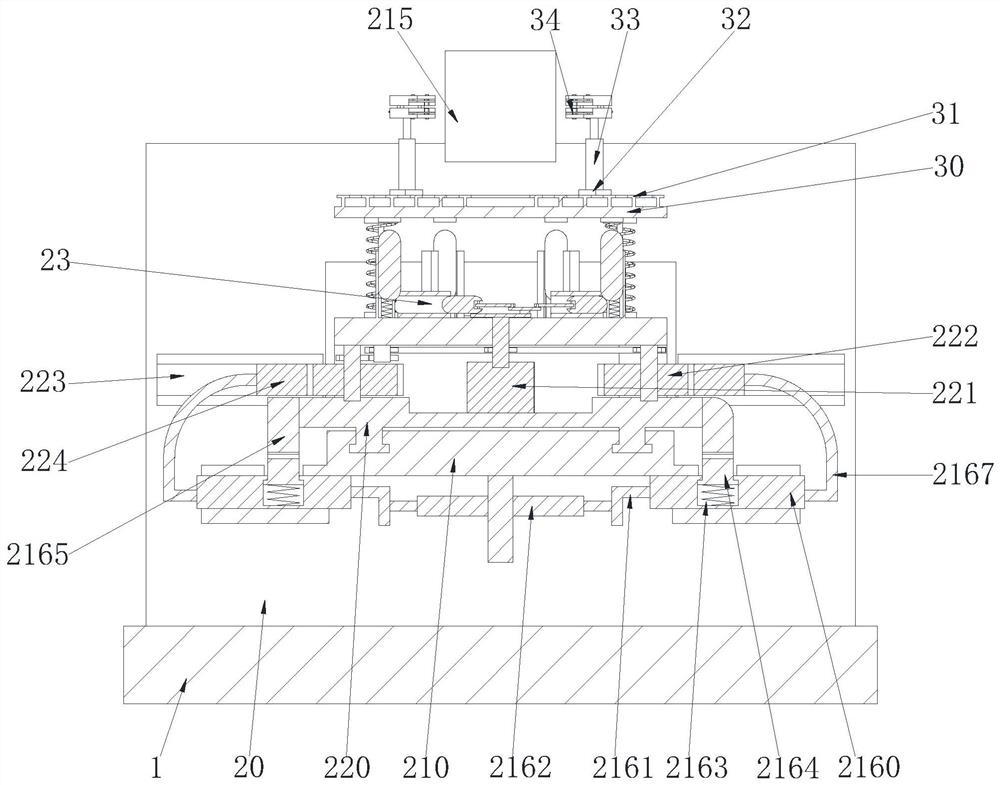

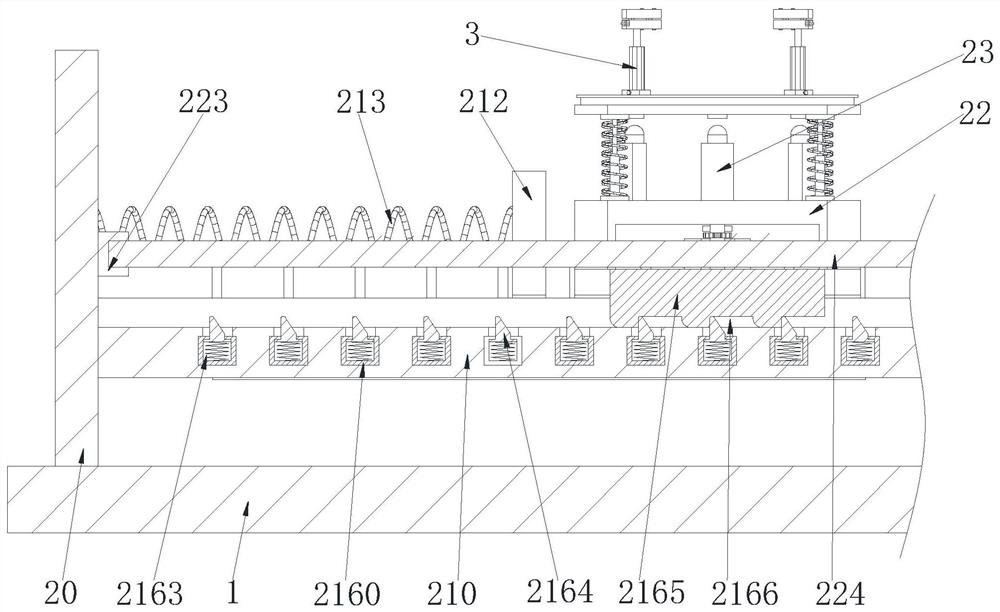

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0032] A new energy vehicle electronic control circuit board testing system, comprising a base 1, a detection device 2 and a clamping unit 3, the detection device 2 is provided on the upper surface of the base 1, and the clamping unit 3 is provided on the detection device 2; wherein:

[0033] The detection device 2 includes a detection riser 20, a collision detection unit 21, a drive unit 22 and a vibration detection unit 23. The detection riser 20 is symmetrically installed on the upper surface of the base 1, and a collision detection unit 21 is arranged between the detection risers 20. , the collision detection unit 21 is provided with a driving unit 22, and the driving unit 22 is provided with a vibration detection unit 23; during specific work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com