Variable-speed control assembly for electric device

A technology for controlling components and electrical equipment, applied in the direction of electrical components, electric components, motor control, etc., can solve problems such as high maintenance and repair costs, increased wear sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

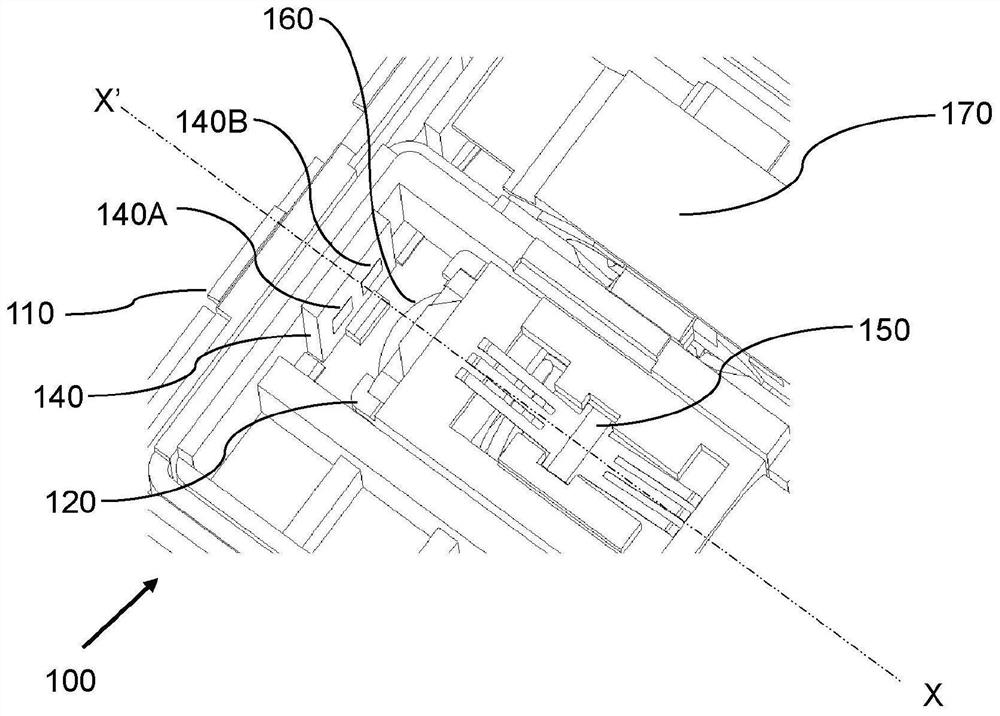

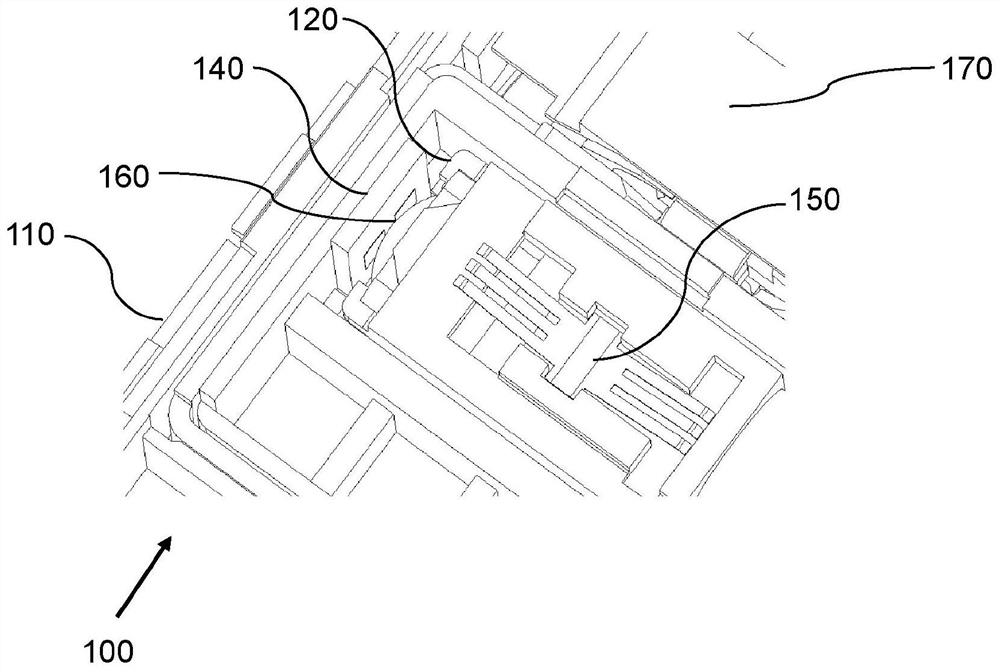

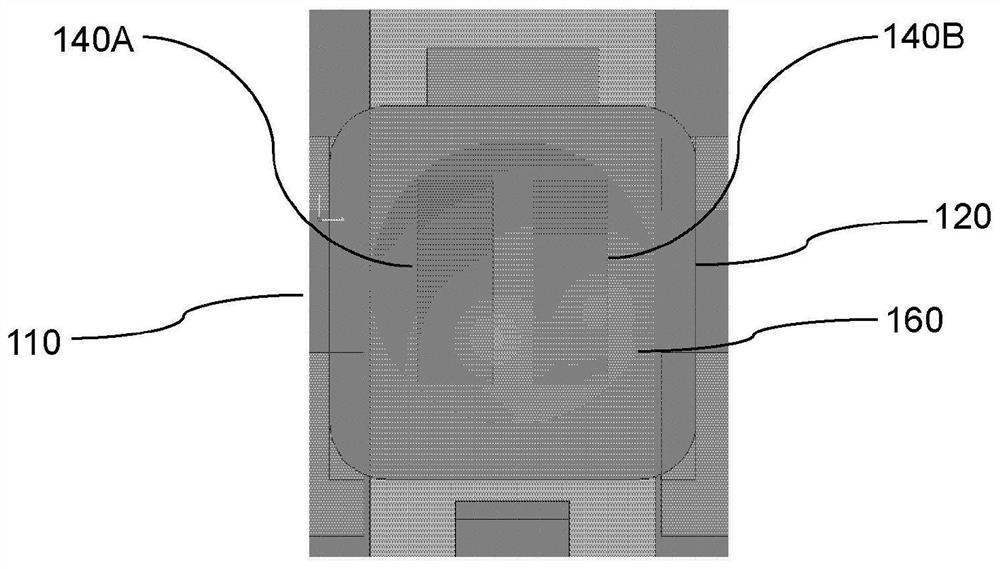

[0028] will now be referred to in this Figure 1 to Figure 4 Preferred embodiments of the present invention are described. These embodiments include a variable speed control assembly 100 for use with a power tool having an electric motor, including, for example, a drill, grinder, sander, saw, rotary drive tool, and the like. It should be appreciated and understood that although this embodiment is described as being used with a power tool, this is for functional purposes only and that alternative embodiments of the invention may of course be used with other types of electrical equipment, such as electric garden tools . Furthermore, although the embodiments of the present invention described herein refer to electrical equipment including electric motors, it should be understood that alternative embodiments of the present invention can also be applied to electrical equipment that includes solenoid-type electromechanical units to achieve The operational movement (eg, reciprocati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com