A glassy coated positive electrode material and preparation method thereof

A kind of positive electrode material, glassy state technology, applied in the field of glassy state coated positive electrode material and its preparation, can solve the problems such as not being able to block the electrolyte erosion well, partial contact of the electrolyte, difficult to uniform dense coating, etc. , to achieve the effect of improving long-term cycle performance, benefiting the stability of material structure, and improving high-temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

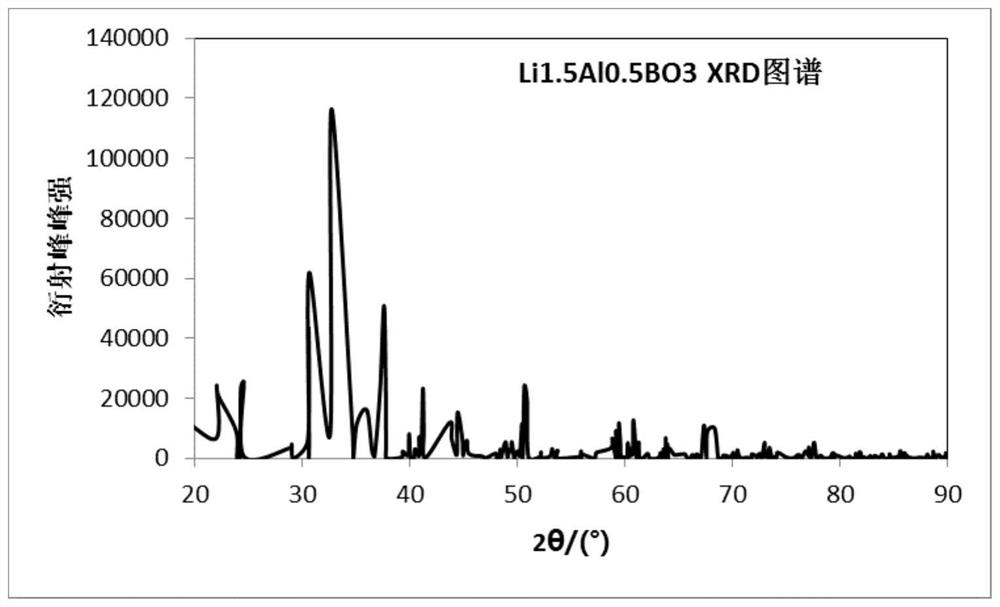

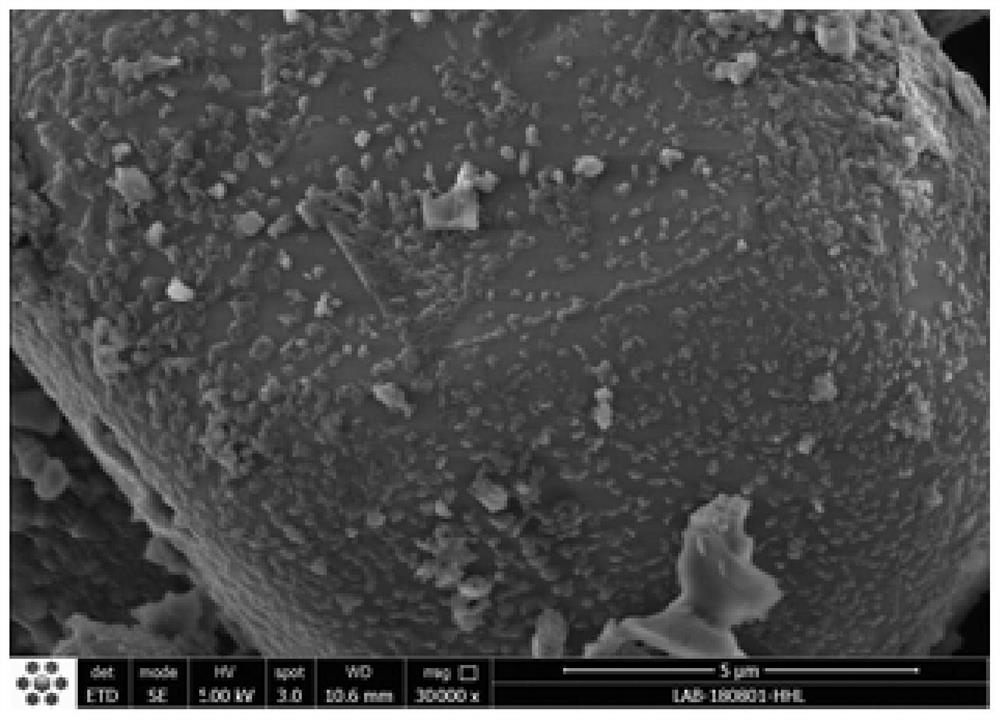

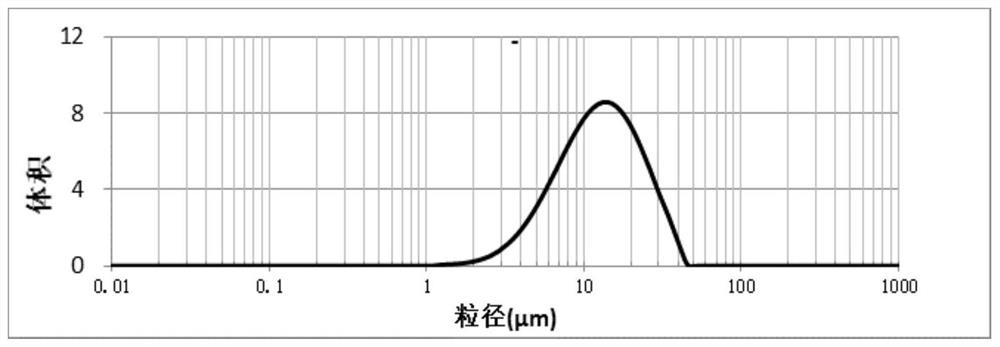

[0043] The glassy coated positive electrode material of this embodiment includes the positive electrode material matrix Li 1.04 Ni 0.6 mn 0.2 co 0.2 al 0.01 o 2 And the glassy substance Li coated on the surface of the positive electrode material matrix 1.5 al 0.5 BO 3 .

[0044] The preparation method of the glassy coated positive electrode material of this embodiment comprises the following steps:

[0045] (1) According to the cathode material matrix Li 1.04 Ni 0.6 mn 0.2 co 0.2 al 0.01 o 2 Design ratio, weigh 10kg precursor Ni 0.6 mn 0.2 co 0.2 (OH) 2 , battery-grade lithium carbonate 4.18kg, aluminum hydroxide 84.78g (above purity is all by 100%), join in the high-speed mixer together, mix 30min with 1000rpm, visual inspection has no white spots after the mixing is completed, obtains the mixture;

[0046] (2) Using a bell furnace, put the mixture obtained in step (1) into a sagger, put it into a sintering device, and use a 10m 3 Air is passed at a rate of...

Embodiment 2

[0070] The glassy coated positive electrode material of this embodiment includes the positive electrode material matrix Li 1.08 Ni 0.5 mn 0.3 co 0.2 mn 0.02 Mg 0.02 o 2 And the glassy substance Li coated on the surface of the positive electrode material matrix 2.4 al 0.2 BO 3 .

[0071] The preparation method of the glassy coated positive electrode material of this embodiment comprises the following steps:

[0072] (1) Press Li 1.08 Ni 0.5 mn 0.3 co 0.2 mn 0.02 Mg 0.02 o 2 The ratio of weighing 10kg precursor Ni 0.5 mn 0.3 co 0.2 (OH) 2 , battery-grade lithium carbonate 4.35kg, magnesia 87.97g (the above purity is all pressed 100%), join in the high-speed mixer, mix 5min with the speed of 800rpm, then mix with the speed of 1000rpm for 30min, after the mixing completes, there is no White spots, get the mixture;

[0073] (2) Using a bell furnace, put the mixture obtained in step (1) into a sagger, put it into a sintering device, and use a 10m 3 Air is passe...

Embodiment 3— Embodiment 7

[0087] The difference between Example 3-Example 7 and Example 1 is that the positive electrode material matrix, coating material, matrix calcination temperature and constant temperature time, coating material treatment temperature and time are different, and other parameters are the same, see Table 1 for details.

[0088] The characteristics of the glassy coating type positive electrode material of table 1 embodiment 3-7

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com