An automatic tab folding mechanism

A pole-ear, automatic technology, applied in structural parts, primary batteries, battery assembly machines, etc., can solve the problems of high labor cost, poor operation convenience, uneven bending positions of pole ears, etc., to improve quality and consistency, The effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

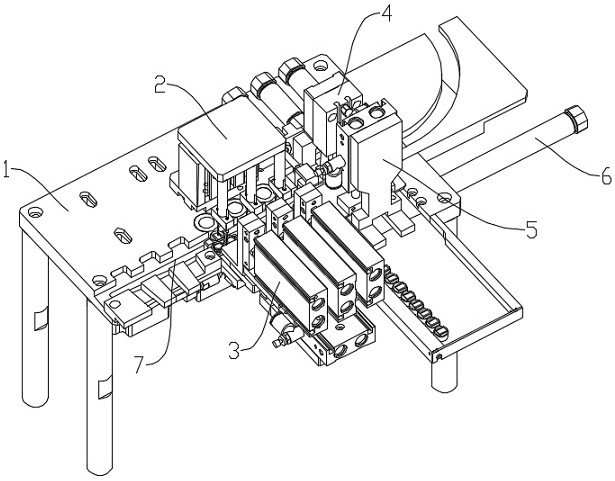

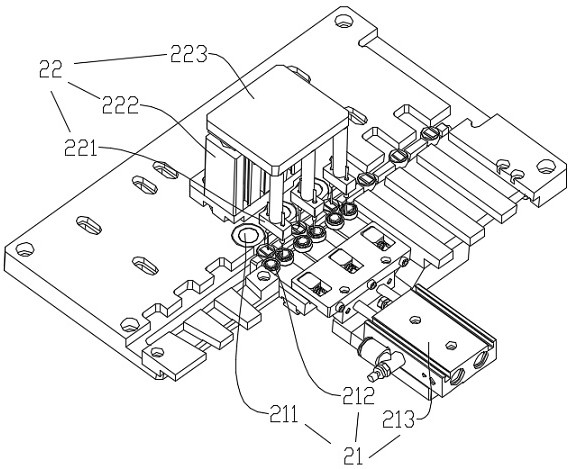

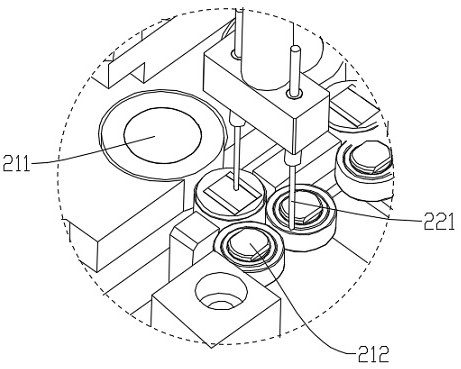

[0024] Such as figure 1 As shown, in a preferred embodiment, the automatic tab folding equipment of the present invention mainly includes a frame 1, an angle alignment mechanism 2, a tab folding mechanism 3, a shaping mechanism 4, a sorting mechanism 5, and a material pushing mechanism 6 . The frame 1 is provided with a feeding trough 7, and the battery cells move along the extension direction of the feeding trough 7, passing through the angle correction mechanism 2, the tab folding mechanism 3, the shaping mechanism 4, the sorting mechanism 5, and the pushing mechanism 6, Among them, the angle alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com