A fast-laying railway engineering cable

A railway engineering and fast technology, applied in the direction of cable joints, circuits, electrical components, etc., can solve problems such as troublesome operation, and achieve the effect of easy docking, good traction effect, and preventing the sliding of the movable ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

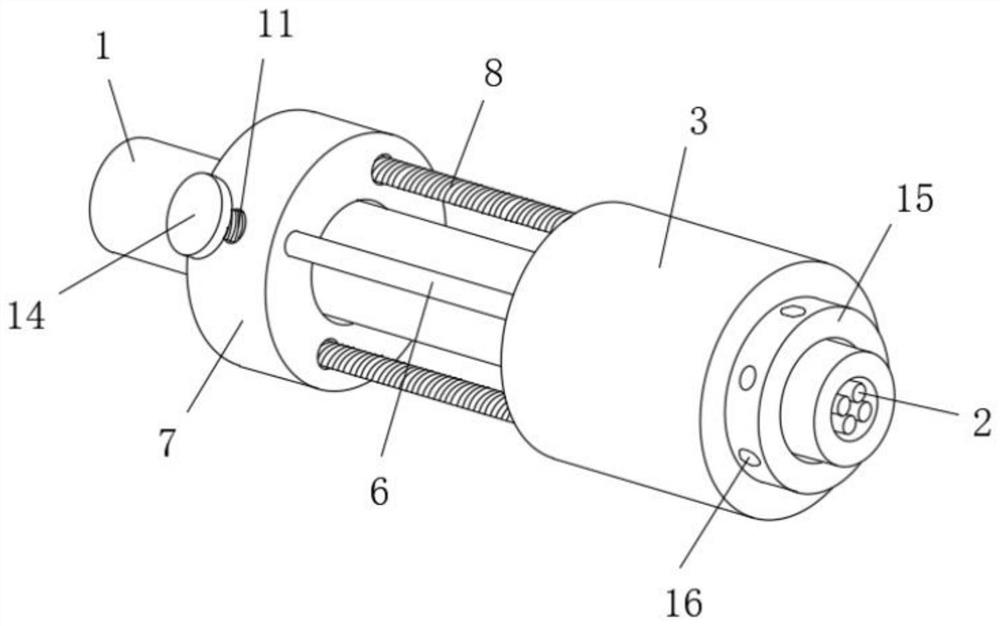

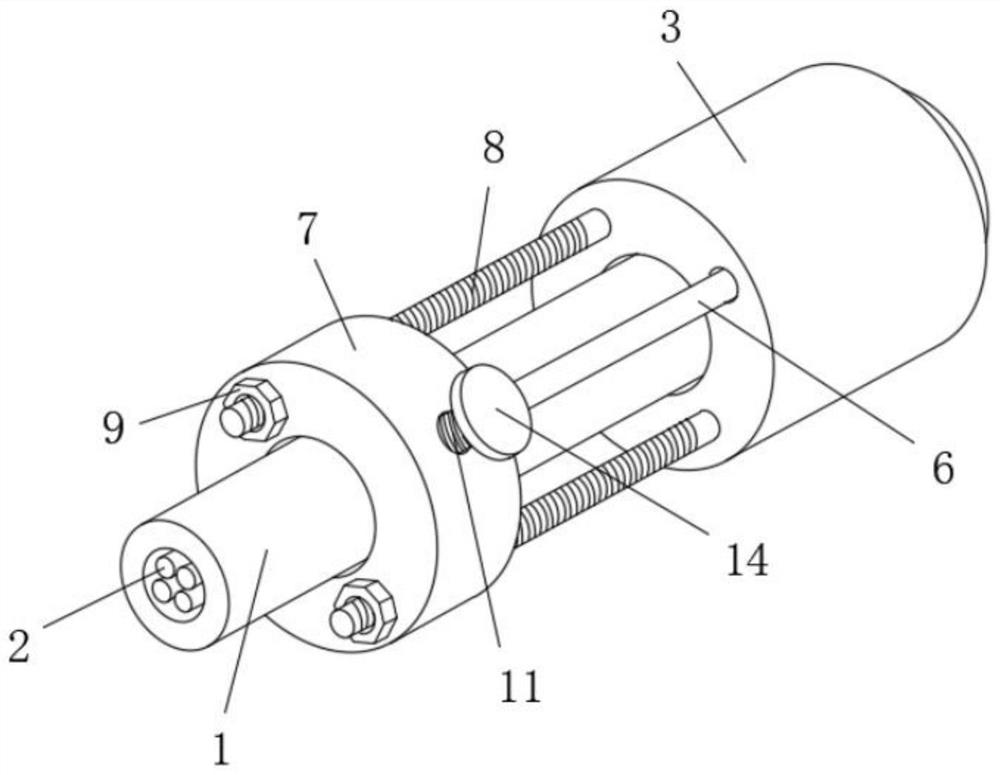

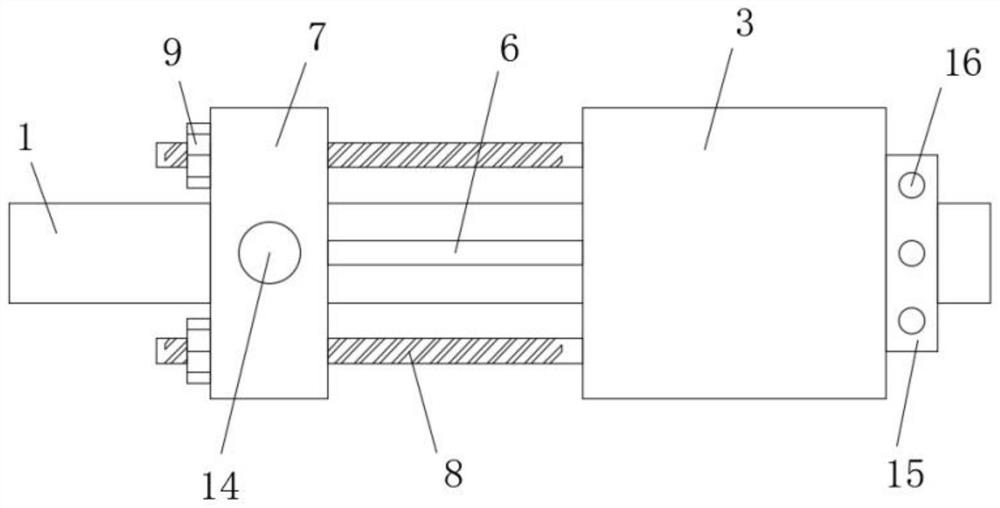

[0030] refer to Figure 1-8 , a railway engineering cable that can be quickly laid, including a cable body 1, a cable core 2 is provided inside the cable body 1, a butt joint protection collar 3 is provided on the outer wall side of the cable body 1 sliding sleeve, and the butt joint protection collar 3 The inner wall is provided with a chute 4, the inner wall of the chute 4 is sealed and slidably connected with a slip ring 5, and the slip ring 5 is connected with the outer wall of the cable body 1 by a sealing and sliding sleeve, and one side of the slip ring 5 is symmetrically fixedly connected with two connecting rods 6. Both ends of the two connecting rods 6 extend to the outside of the docking protective collar 3 and are fixedly connected with the same movable ring 7, and the movable ring 7 is sleeved and connected with one side of the outer wall of the cable body 1, and the movable rings 7 are connected to each other. Two clamping assemblies are arranged symmetrically on...

Embodiment 2

[0032]Further improvement on the basis of Embodiment 1: the side of the butt joint protective collar 3 away from the convex ring 15 is symmetrically fixedly connected with two limit screw rods 8, and one side of the two limit screw rods 8 respectively passes through the movable ring 7 away from the One side of the docking protective collar 3 extends to the outside of the movable ring 7, and one side of the two limit screw rods 8 is threaded with a limit nut 9, and one side of the two limit nuts 9 is connected to the movable ring 7 respectively. The side away from the docking protective collar 3 is in contact, and through the cooperation of the limit screw 8 and the limit nut 9, the butt joint protective collar 3 and the movable ring 7 can be limited. The arc-shaped groove 10, the inner wall of the arc-shaped groove 10 away from the cable body 1 is threaded through the clamping screw 11, and the end of the clamping screw 11 close to the cable body 1 is rotatably connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com