Video welding mask

A welding mask and video technology, which is applied in eye masks, eye surgery, etc., can solve the problems of incomplete filtering of harmful light, poor protection and visibility of masks, and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

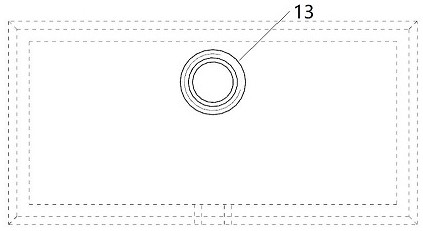

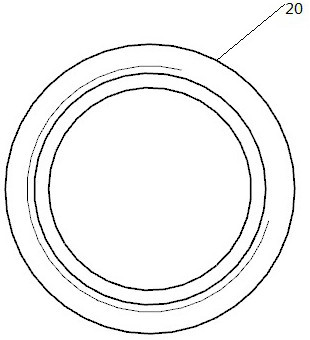

[0051] Concrete embodiment: the mask main body is handmade, selects display to be 3 inch screens, and camera selects 2,000,000 pixel common objective lens cameras; Battery selects 3.7V mobile phone lithium battery to be contained in the display, battery capacity 1200mAh; Filter system consists of a filter glass Composed of transparent glass, the filter lens is No. 7 depth welded glass, the transparent lens is on the outside, the filter lens and transparent lens are screwed onto the boss by the lens barrel; an O-shaped rubber gasket is installed between the glass at the bottom of the lens barrel , here the rubber gasket plays the role of anti-loosening and cushioning; the filter lens can be easily removed during spot welding, so that the best view can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com