Sand sieving machine for small building machine

A technology of construction machinery and sand screening machine, which is applied in the direction of screening, conveyor, solid separation, etc., can solve the problems of high sand feeding height, increased construction tasks, heavy sand screening equipment, etc. High efficiency and light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

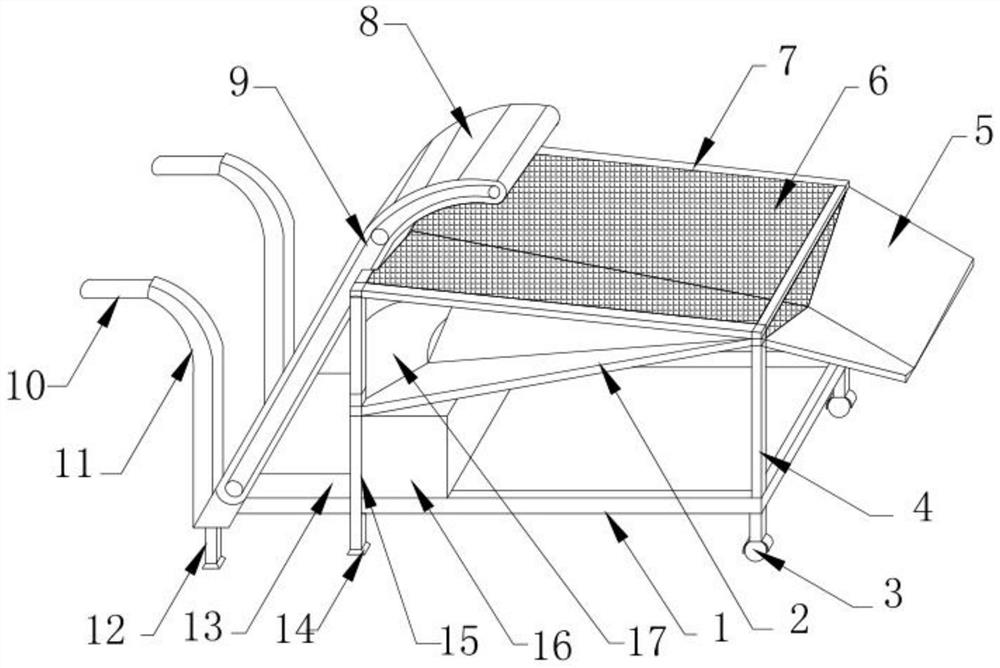

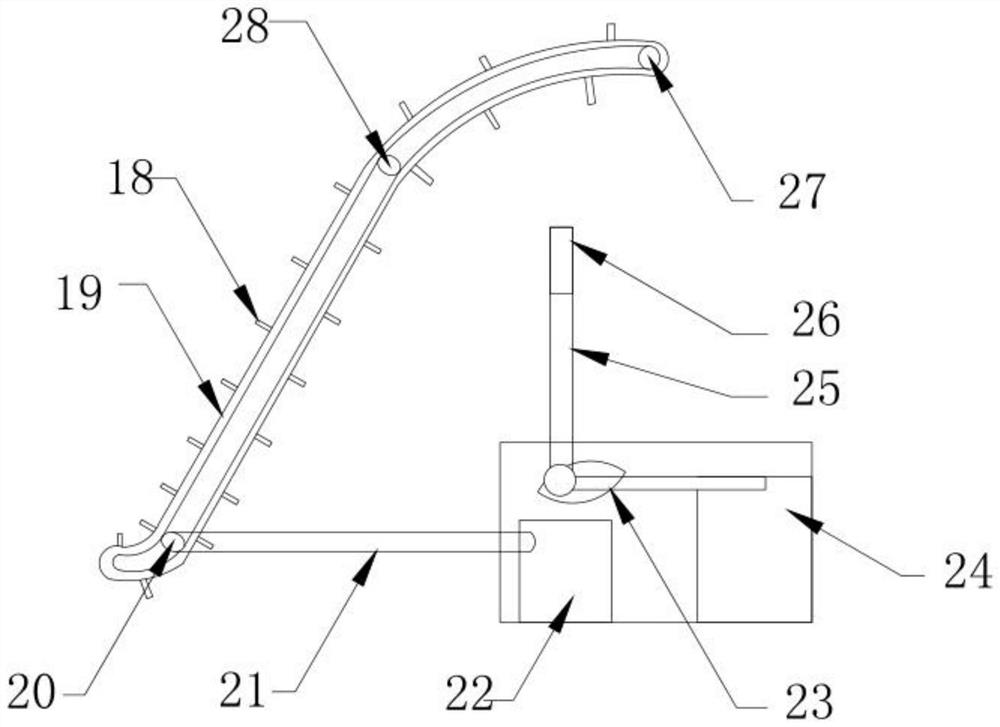

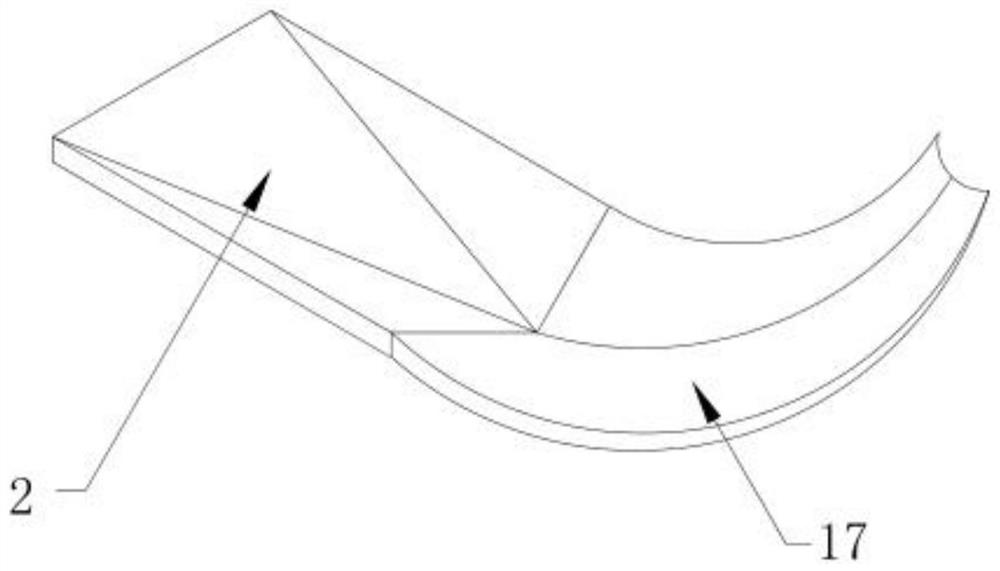

[0025] from Figure 1-3 It can be seen that the sand screening machine for small construction machinery in this embodiment includes a sand screening device 1 and a conveying device 8, the right part of the sand screening device 1 is provided with a universal wheel bracket 4, and the lower part of the universal wheel bracket 4 is provided with The universal wheel 3, the universal wheel 3 is rotationally connected with the universal wheel bracket 4 through the rotating shaft, the universal wheel 3 is symmetrically provided with two universal wheels 3 adopting a special thickened hub, the body is stable, easy to move, and the sand screening device 1 The left part is provided with a machine base bracket 15, and the bottom of the machine base bracket 15 is provided with a fixed machine foot 14, which is made into a square platform shape, and the fixed machine foot 14 cooperates with the auxiliary machine foot 12 to make the placement of the whole device more stable. The fixed machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com