Finishing correction die suitable for special material welded pipe and finishing machine

A technology for welded pipes and special materials, which is applied in the field of finishing, can solve the problems of scratches on the outer wall of welded pipes made of special materials, high yield strength of zirconium materials, and affect the appearance quality, etc., so as to avoid scratches, large diameter adjustment ability, and ensure production rhythm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

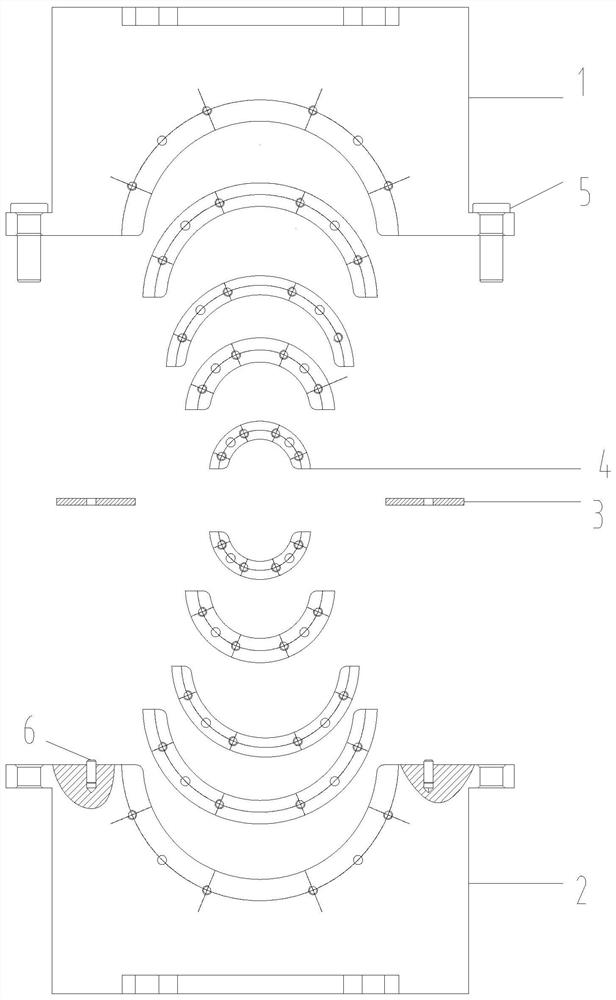

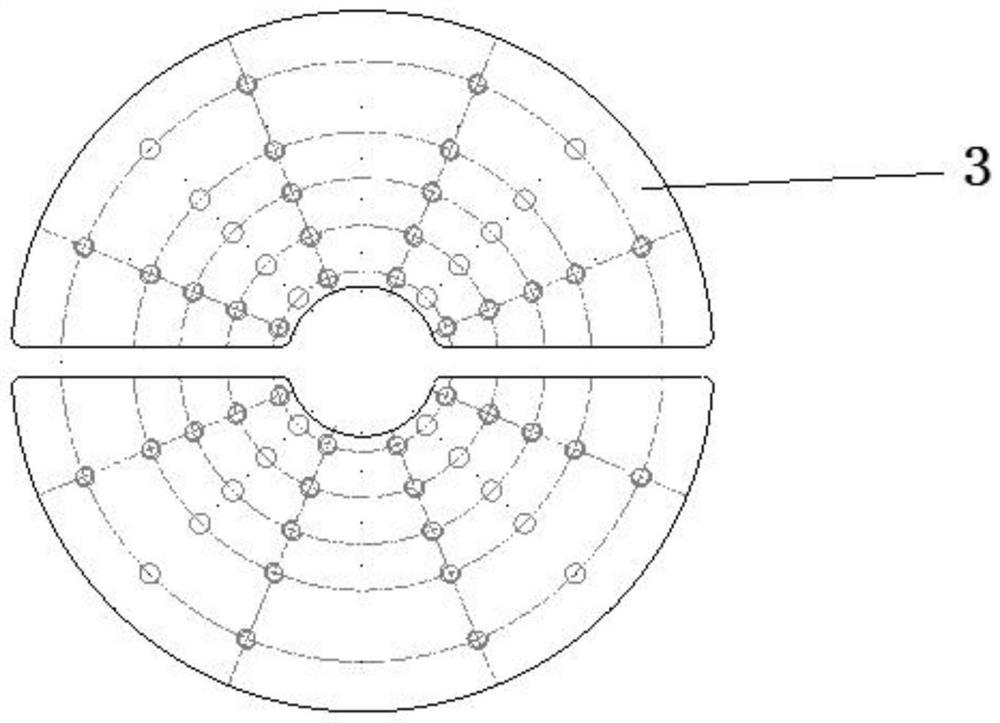

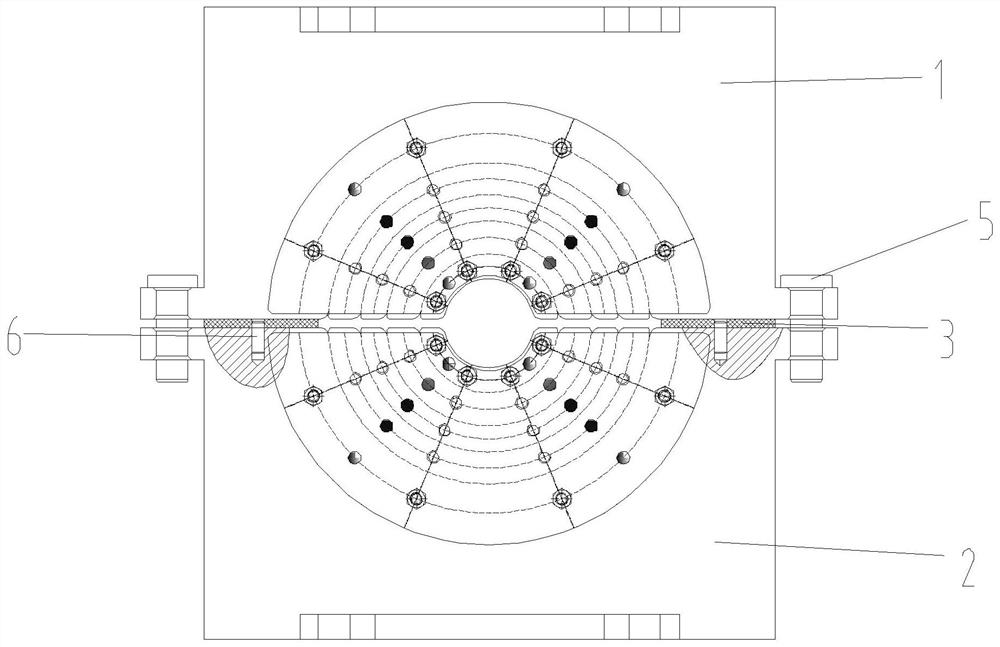

[0032] Such as figure 1 As shown, a finishing correction mold suitable for special material welded pipes of the present invention includes an upper mold base 1 and a lower mold base 2, the upper mold base 1 and the lower mold base 2 are fixed by positioning pins 5, and the lower mold base 2 and the lower mold base 2 form a mold cavity after the mold is closed, and tiles 4 of different sizes are installed and removed through the stop pins in the mold cavity. These cavity tiles 4 are used in combination, so that they can be quickly replaced in actual processing; A mold clamping gap 8 is preset between the lower mold base 2 and the corresponding inner end surface of the lower mold base 2 after mold clamping, and an adjustment backing plate 3 is provided at each of the two mold clamping gaps 8, and the adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com