Pushing mechanism of mechanical polishing equipment for machining

A technology of mechanical processing and pushing mechanism, applied in machine tools, metal processing equipment, grinding/polishing equipment, etc. suitable for grinding workpiece planes, can solve the problems of sliding, difficult to stabilize workpiece pushing, low stability, etc. The process is stable, the workpiece processing is stable, and the effect of strengthening and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

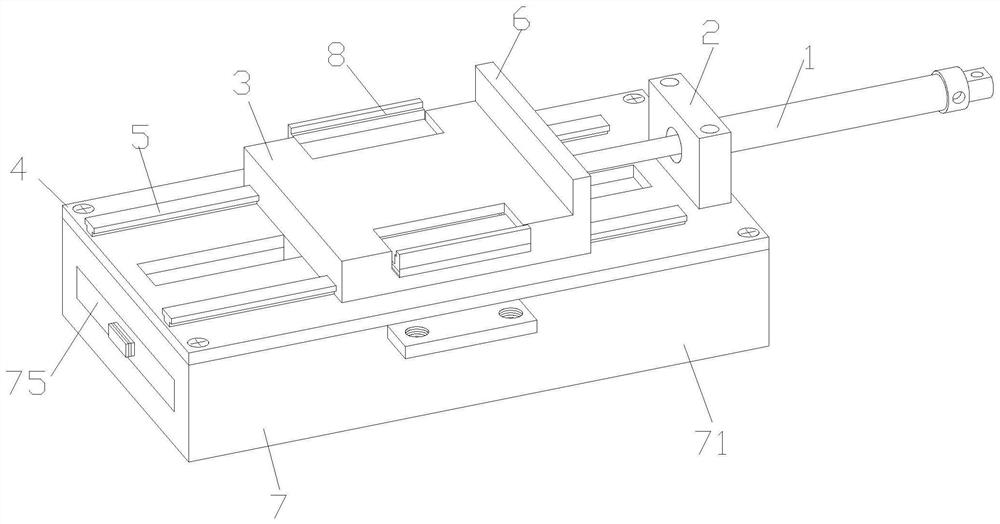

[0030] see figure 1 , the present invention provides a push mechanism for mechanical grinding equipment through improvement, including a cylinder 1 and a side plate 2, the cylinder 1 is installed on the right end side plate 2, and the piston rod on the left side of the cylinder 1 passes through The right end of the side plate 2 is fastened to the top of the right end of the slide plate 3, and the slide plate 3 is slidably mounted on the guide rail 5 fastened to the top end of the bottom plate 4, and the right end of the top of the slide plate 3 is provided with a push plate 6.

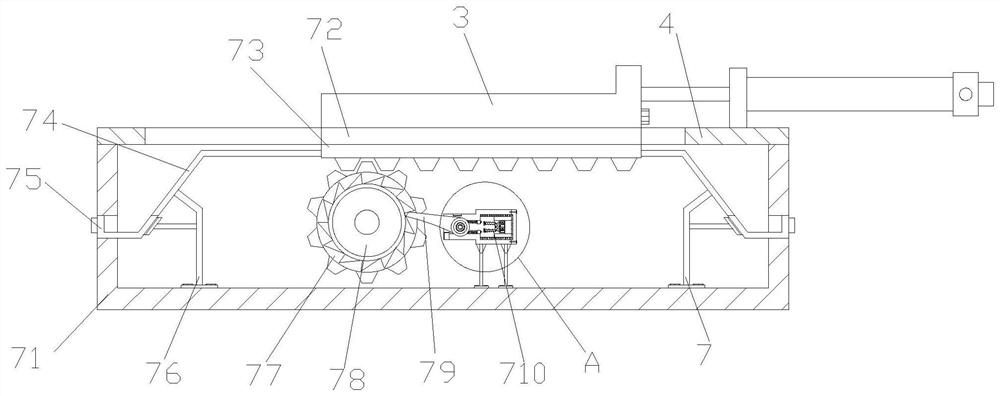

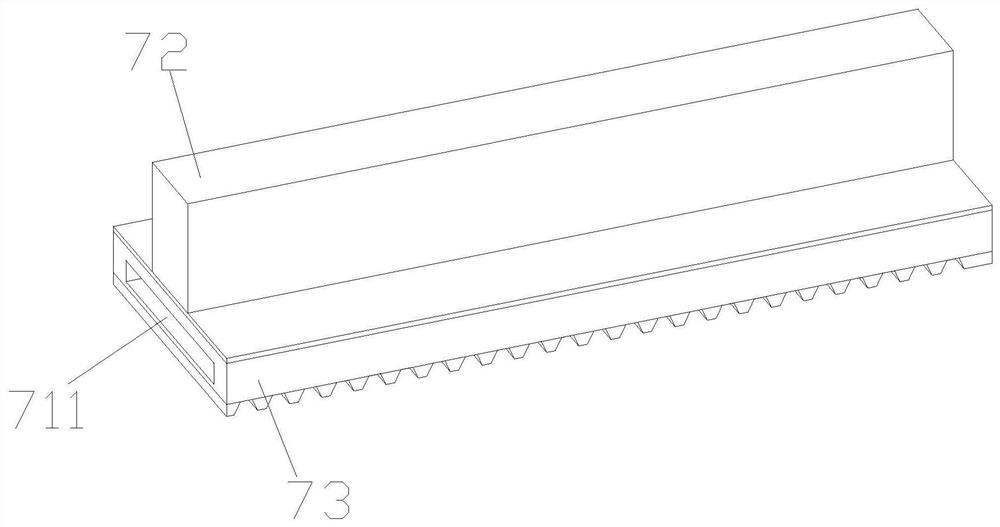

[0031] see figure 2 and image 3, the present invention provides a push mechanism for mechanical grinding equipment through improvement, the auxiliary reinforcement mechanism 7 is arranged on the bottom of the bottom plate 4, the extension mechanism 8 is arranged on the inner side of the slide plate 3, and the auxiliary reinforcement mechanism 7 includes a pre-embedded shell 71. Connecting plate 72,...

Embodiment 2

[0036] The present invention provides a push mechanism for mechanical grinding equipment through improvement. The middle part of the left and right ends of the side plate 2 is provided with a round hole, and the inner diameter of the round hole is 1.5 cm larger than the outer diameter of the output shaft of the cylinder 1. It is convenient to make the output shaft on the left side of the cylinder 1 stably pass through the side plate 2 and connect to the slide plate 3. The guide rail 5 is a T-shaped structure, and the bottom of the slide plate 3 is provided with a matching T-shaped groove, which makes the horizontal movement of the slide plate 3 more stable.

[0037] The present invention provides a push mechanism for mechanical grinding equipment through improvement, and its working principle is as follows;

[0038] First, firstly, the device is fixedly installed on the specified position on the workpiece grinding equipment as a whole, and the embedded shell 71 needs to be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com