A cutting burr grinding device for aluminum profile processing

An aluminum profile processing and burring technology, which is applied to grinding drive devices, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., can solve problems such as consuming more human resources, avoid potential safety hazards and facilitate normal operation. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments.

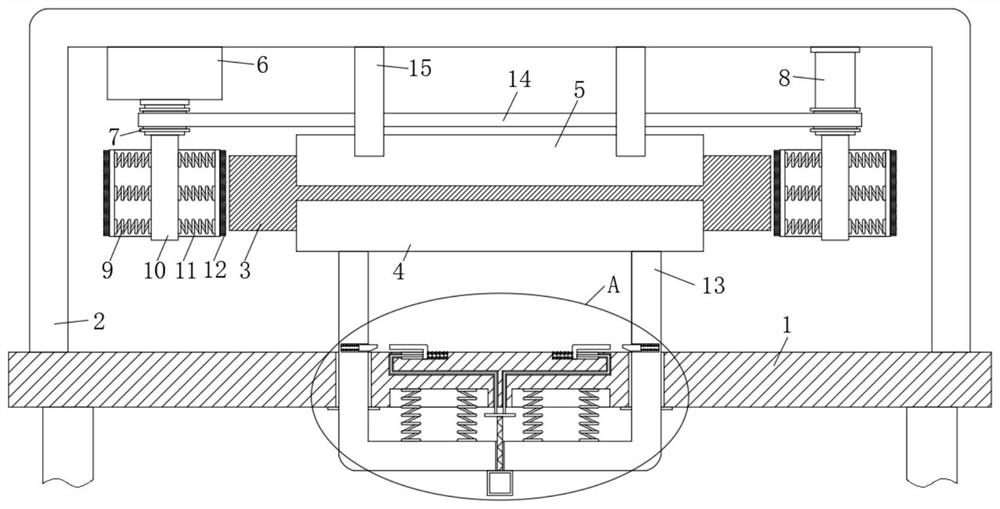

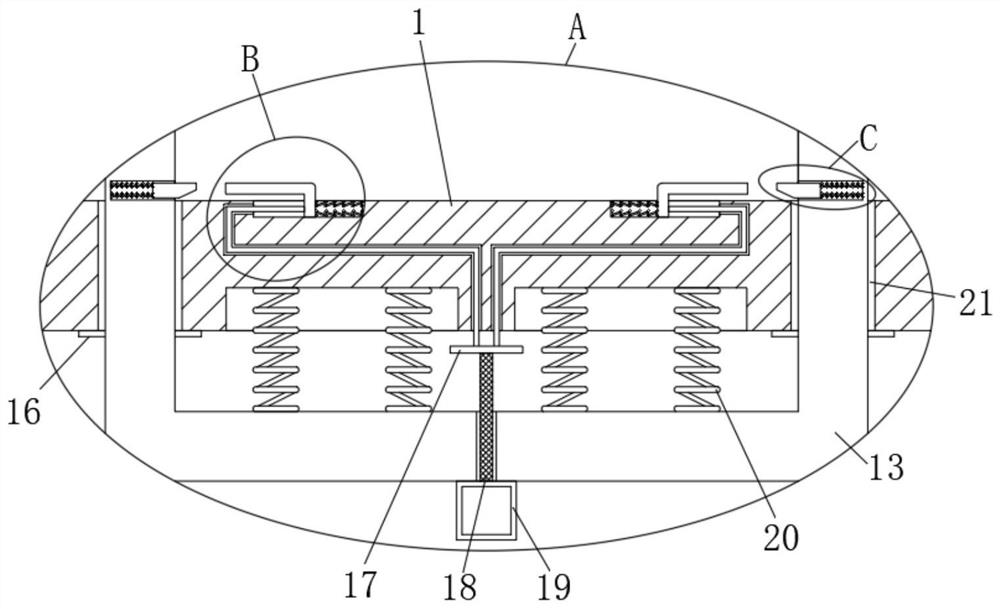

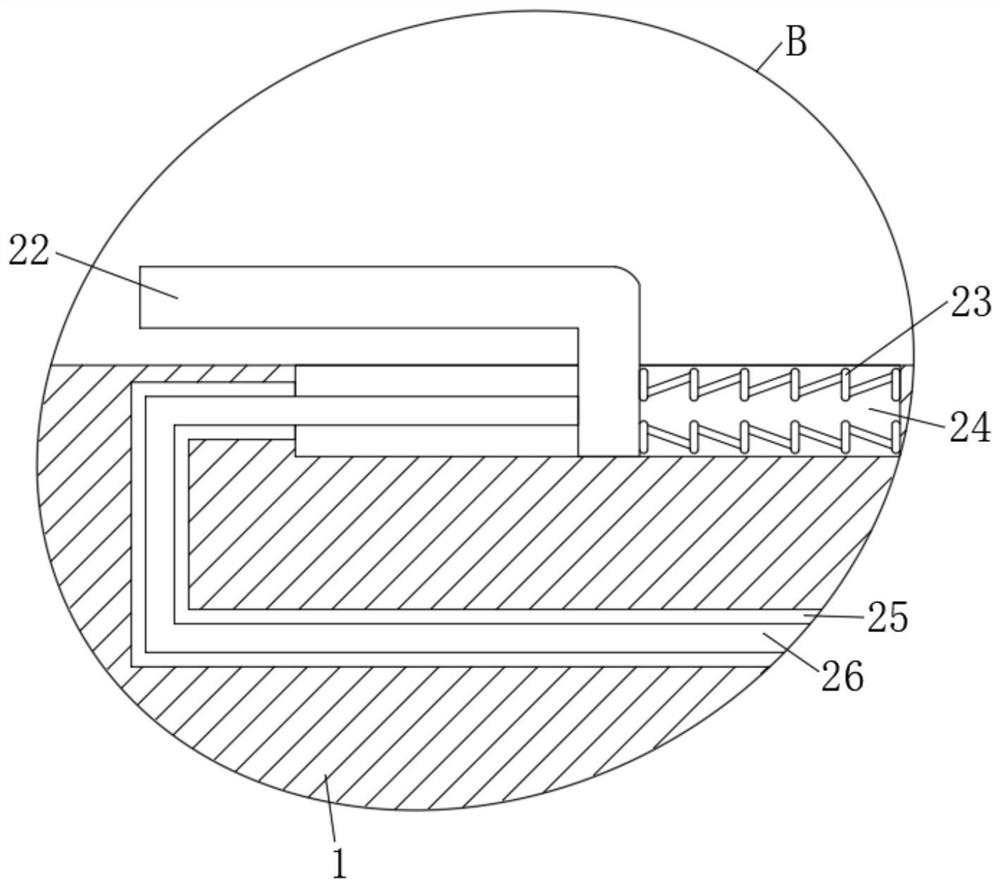

[0025] Refer Figure 1-5 One aluminum profile is processed with a cutting wool grinding device, including a table 1, and a plurality of support legs are provided with a plurality of support legs. The lower ends of the plurality of support legs have a traveling mechanism, and the traveling mechanism is a locking universal wheel. The setting of the traveling mechanism can facilitate the workstock 1 to move the position according to the actual situation, facilitate the normal use of the user, and lock the universal wheel to avoid the workstock 1 easily displacement, to ensure its stability, the upper end of the table 1 There is a mounting rack 2, the bottom of the mounting frame 2 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com