Tire and tire mold for tire vulcanizing

A tire mold and tire technology, which is applied in the field of railway freight cars, can solve the problems of poor visual effect of tire surface appearance, etc., and achieve the effect of improving recognition, ensuring attenuation degree, and ensuring recognition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

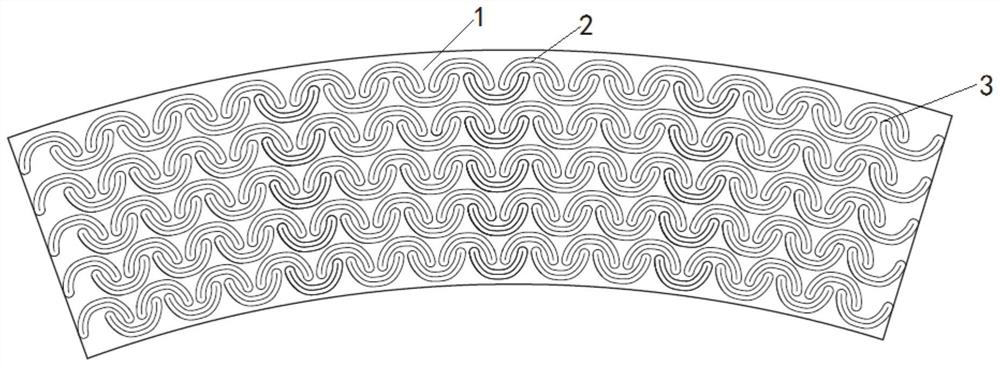

[0056] In a typical embodiment of the present invention, refer to figure 1 and Figure 7 As shown, a tire is equipped with an identification area 1, and the identification area is located on the sidewall of the tire.

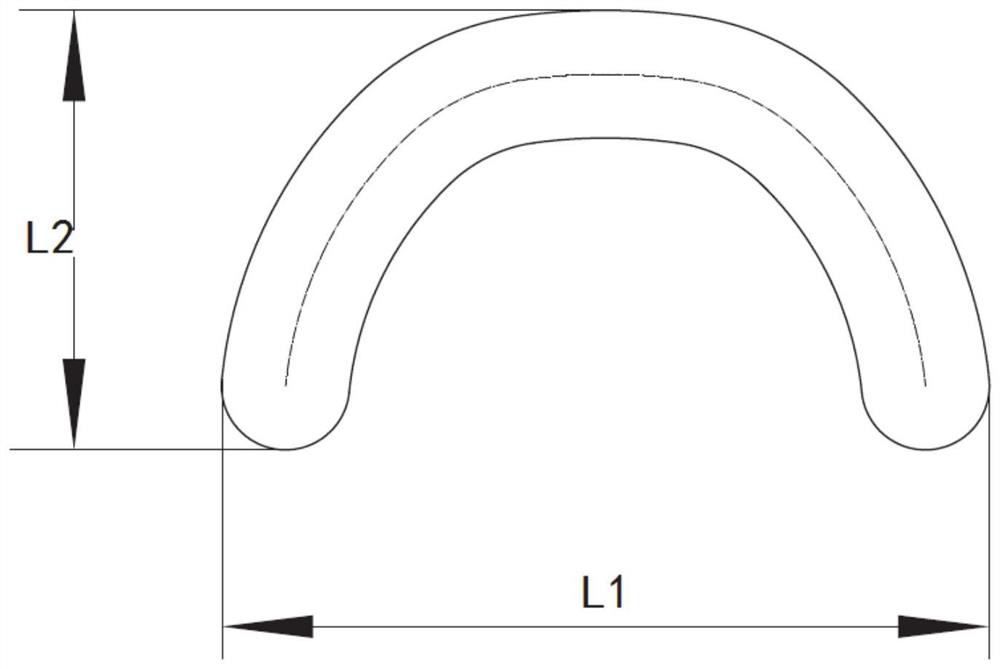

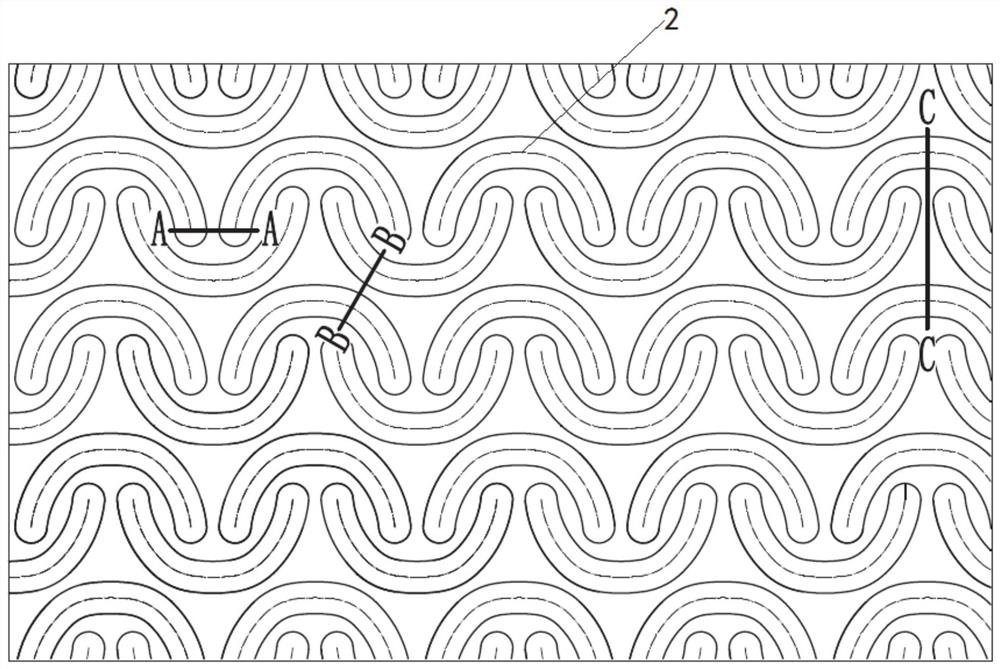

[0057] The marking area 1 has a relatively bright part and a dark part. The dark part is provided with a texture, and the texture protrudes from the outer surface of the tire. The chain 3 includes a plurality of curved portions 2 that protrude from the outer surface of the tire. Two adjacent curved portions 2 of each curved portion chain 3 are arranged at a predetermined distance, and the top end of the curved portion is smaller than the bottom end.

[0058] At least one end of each curved part chain curved part is inserted into the curved inner side of the curved part adjacent to the curved part in the adjacent curved part chain, the curved part is bent, and the direction of the normal line in the curved part is the curved inner side of the curved part, The d...

Embodiment 2

[0071] The differences between this embodiment and Embodiment 1 are:

[0072] refer to Figure 8 As shown, a raised portion 4 is arranged between two adjacent bent portions in each curved portion chain. In some examples, the raised portion is an independent raised portion 4, and the raised portion 4 can be conical or cylindrical. , frustum-shaped, etc., the height of the independent raised part is preferably consistent with the height of the curved part; the setting of the raised part further facilitates the attenuation of light in the curved part chain, and is conducive to the highlighting of the texture.

[0073] All the protrusions in each bending chain are arranged on the same straight line or on the same curve. For the bending chains arranged in rows and columns, the protrusions in two adjacent bending chains arranged at intervals are arranged on multiple straight lines , for a fan-shaped or ring-shaped bent part chain, the protrusions in two adjacent bent part chains ar...

Embodiment 3

[0075] The differences between this embodiment and Embodiment 1 are:

[0076] The curved part is provided with a branch structure, the branch structure is connected to the parent curved part, interspersed in the blank area between the curved parts, the branch structure is connected to the adjacent curved part, the branch structure has a set height, and the height of the branch structure is less than or equal to the curved part the height of.

[0077] The branch structure includes a first connecting portion 5, and / or, also includes a protruding portion 6 disposed inside the bending portion, and / or, also includes a second connecting portion 7 for connecting two bending portions in two adjacent bending portion chains .

[0078] Specifically, in some examples, refer to Figure 9 and Figure 10 As shown, the adjacent bending parts of the same bending part chain are connected by the first connecting part 5, the number of the first connecting part is 1-3, and the interval between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com