Paddle leg composite driving mechanism

A driving mechanism and paddle leg technology, applied in the field of driving mechanism, can solve the problems of low operation efficiency, slow speed, difficulty in meeting land obstacle crossing and underwater propulsion requirements at the same time, etc., and achieve high travel speed, long service life, and high terrain. adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

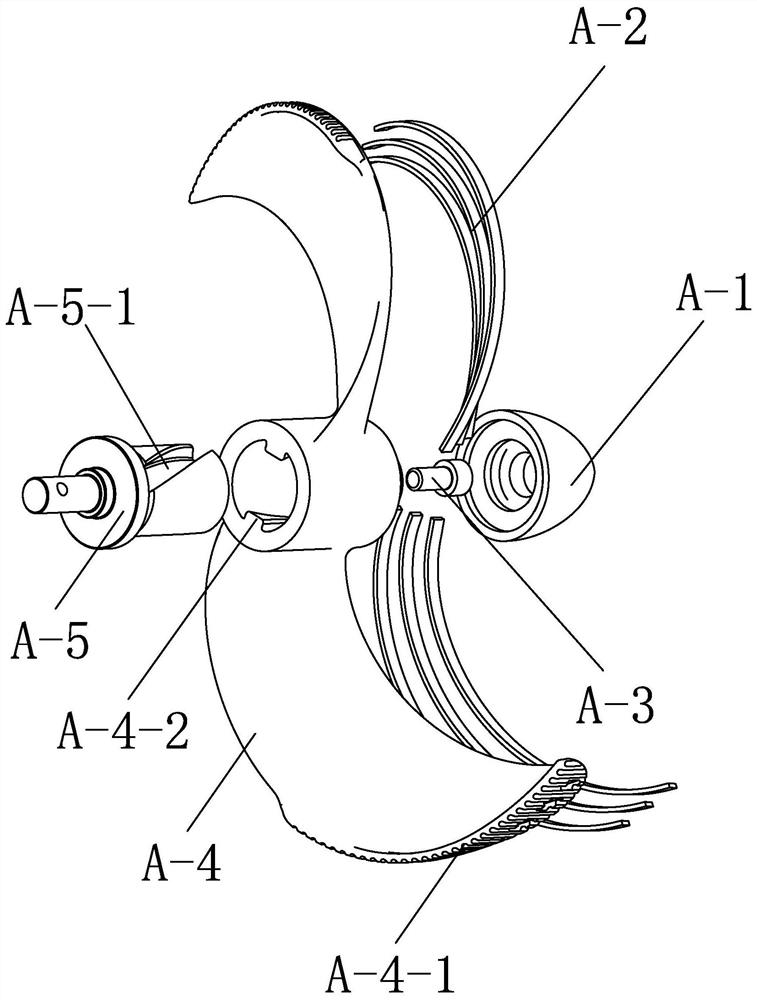

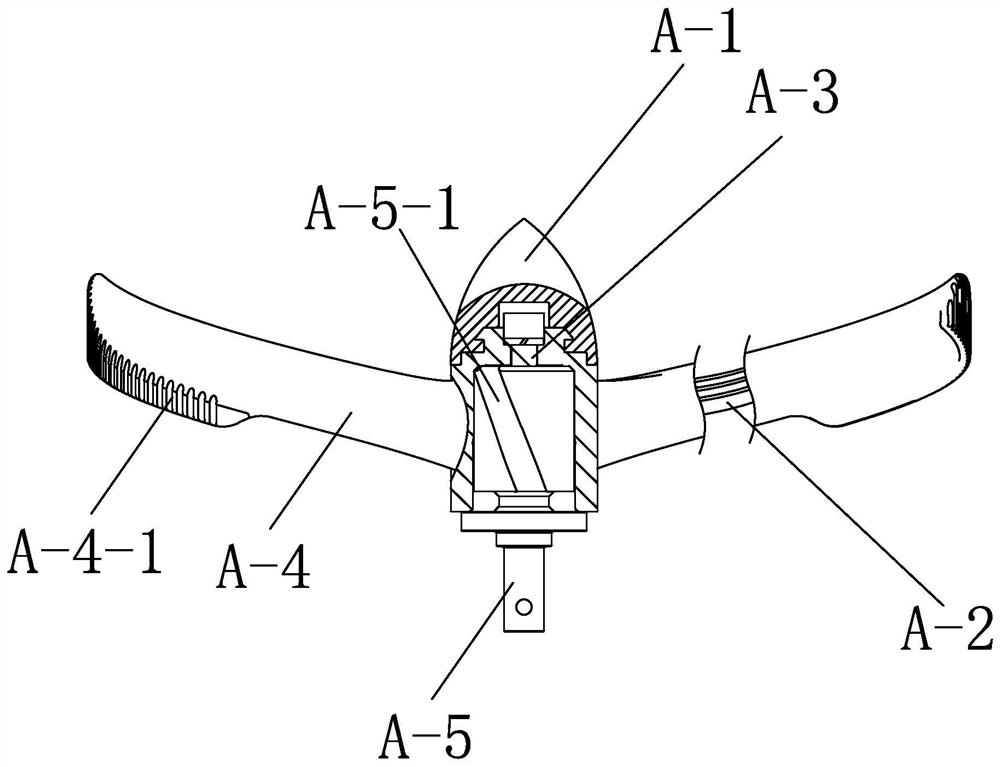

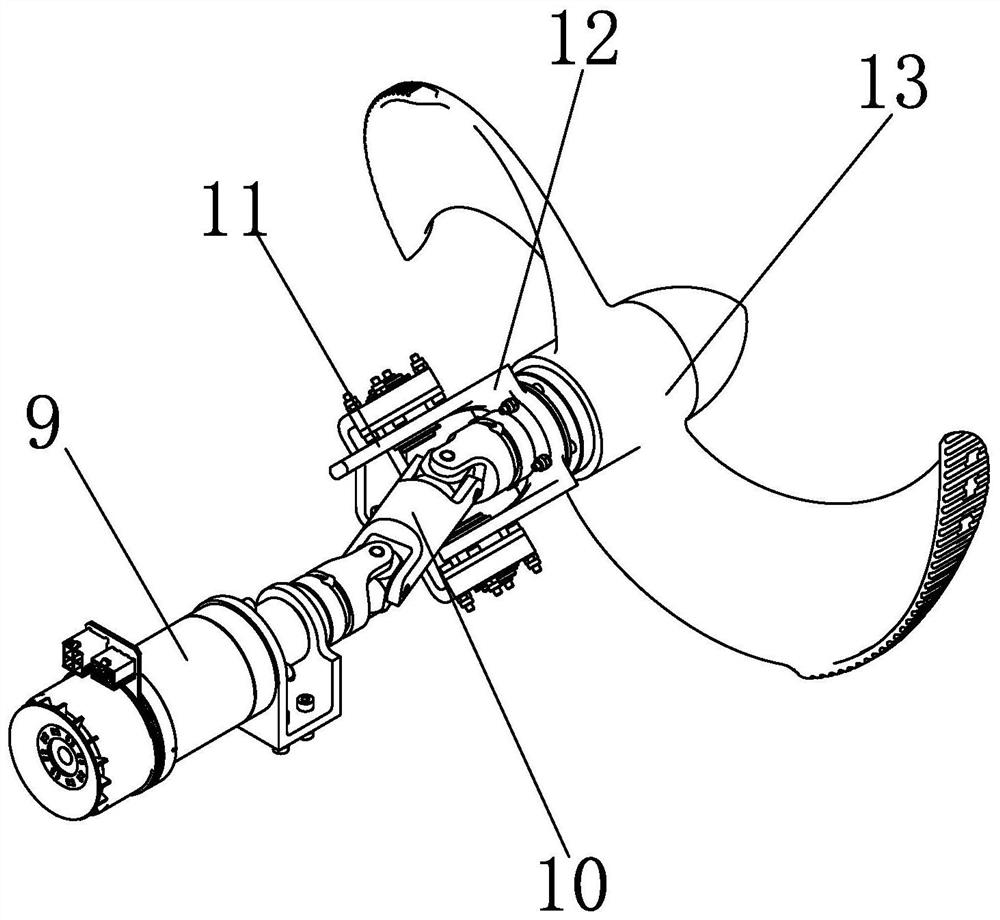

[0019] Specific implementation mode one: combine Figure 1 to Figure 4 To illustrate this embodiment, a paddle leg composite driving mechanism in this embodiment includes a paddle leg drive module and a paddle leg 13, and the paddle leg 13 includes a conical cap A-1, an embedded beam A-2, a fixing screw A-3, a paddle leg The leg base A-4 and the screw shaft A-5, the screw shaft A-5 is provided with a spiral groove A-5-1, the screw shaft A-5 is inserted in the paddle leg base A-4 and rotated by the fixing screw A-3 into the screw hole of the screw shaft A-5, the embedded beam A-2 is embedded in the paddle leg base A-4, and one end of the embedded beam A-2 extends into the screw tenon A-5-1, and the cone cap A-1 is installed on the circular platform protrusion outside the hub of the paddle leg base A-4; the paddle leg base A-4 is a C-shaped propeller blade, and the cone cap A-1 and the paddle leg base A-4 are made of flexible material, the paddle leg drive module is connected w...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 1 to Figure 2 To describe this embodiment, both the conical cap A-1 and the paddle leg base A-4 of this embodiment are made of thermoplastic polyurethane rubber material. With such a setting, it is very flexible and wear-resistant. It is suitable for walking on land and overcoming obstacles. It can withstand ground wear for a long time and has a long service life. It can be divided into two halves by using the helical surface as the parting surface and made by mold overmolding. The cone cap A-1 can also be made by 3D printing by fused deposition and direct mold overmolding. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 1 to Figure 2 To describe this embodiment, a plurality of grooves A-4-1 are provided along the axial direction on the outer end surface of the C-shaped propeller blade of the paddle leg base A-4 of this embodiment. Such setting is convenient for the propeller blade to increase the frictional force of the ground or water body when rotating. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com