High-stability underground coal mine inspection robot

An inspection robot and high-stability technology, applied in the field of robots, can solve the problem that the crawler wheels cannot be adjusted according to the terrain of up and down slopes, and achieve the effect of improving the climbing ability, good stability, and easy to climb uphill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

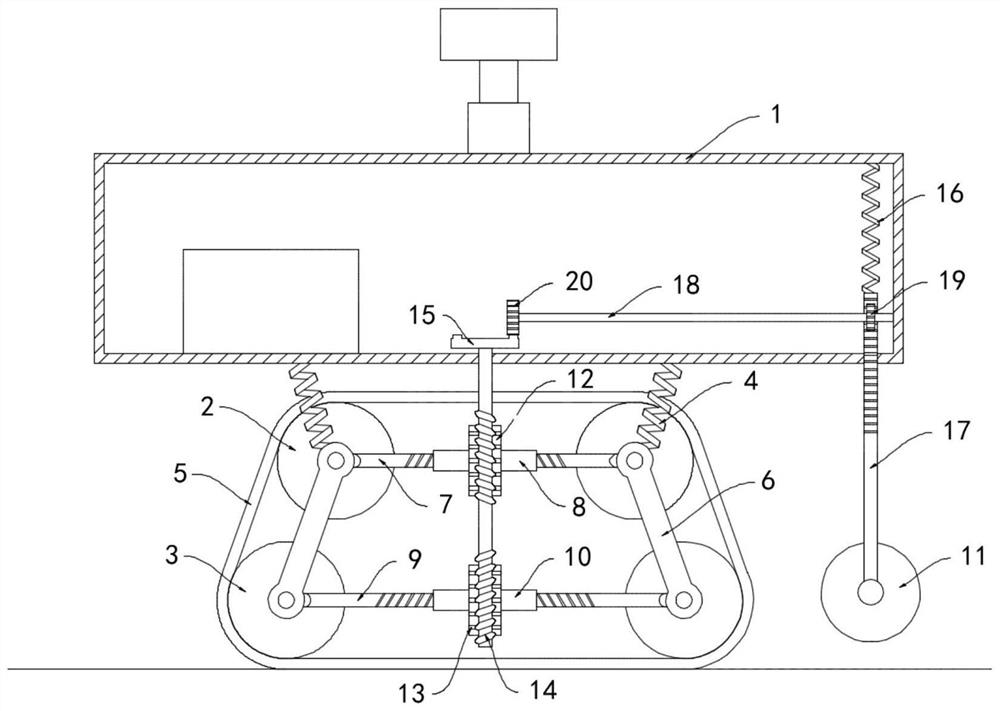

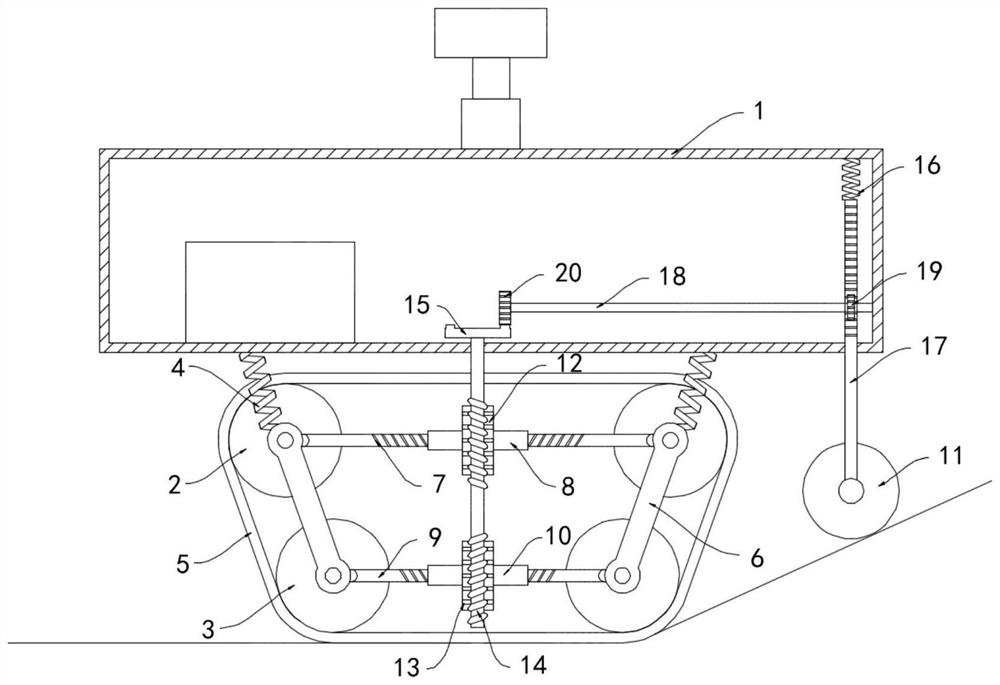

[0018] Such as Figure 1-2 As shown, a high-stability coal mine underground inspection robot includes a car body 1, a driving motor is installed on the lower surface of the car body 1, a driving wheel is installed on the output shaft of the driving motor, and upper and lower sides of the driving wheel are provided. Driven wheel 2, two upper driven wheels 2 are rotationally connected with car body 1 by supporting spring 4 respectively, two lower driven wheels 3 are arranged below the two upper driven wheels 2, driving wheel, upper driven wheel 2 and lower driven wheel 3 are connected by crawlers 5, and the upper driven wheel 2 and the lower driven wheel 3 are connected by connecting rod 6. The upper ends of the two connecting rods 6 are connected with upper threaded rods 7, and the two upper threaded rods 7 are threaded on the surface. The screw direction is opposite, and the external threads of two upper threaded rods 7 are socketed with an upper threaded cylinder 8, and the l...

Embodiment 2

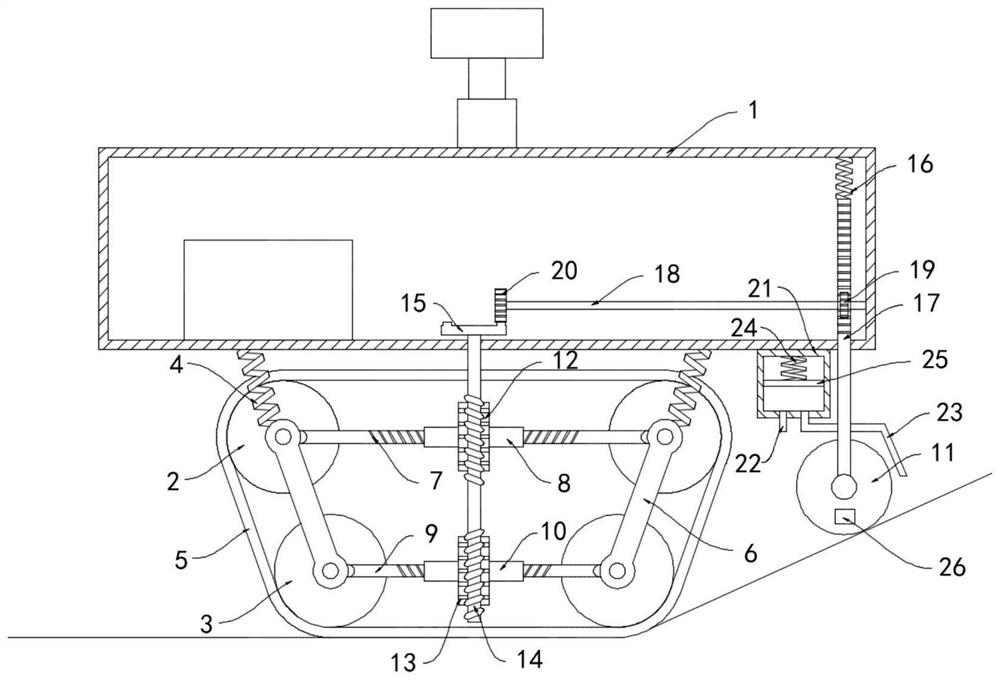

[0024] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is: the bottom surface of the car body 1 is fixedly equipped with a wrecker box 21, and the side wall of the wrecker box 21 is fixedly connected with a one-way air intake pipe 22 and a one-way exhaust pipe. Pipe 23, the one-way air intake pipe 22 only allows outside air to enter the obstacle removal box 21, the one-way exhaust pipe 23 only allows the air in the obstacle removal box 21 to be discharged, and the lower end of the one-way exhaust pipe 23 extends to the detection wheel 11 Set at the location, the piston plate 25 is sealed and slidably connected in the obstacle removal box 21, the piston plate 25 is made of ferromagnetic material, the upper surface of the piston plate 25 is fixedly connected with the inner top surface of the obstacle removal box 21 by the return spring 24, and the detection wheel The sidewall of 11 is equipped with permanent magnet piece 26.

[0025] In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com