Gas pipeline sealing detection device capable of being pressurized and with scale, detection method and application

A gas pipeline and sealing detection technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of unhygienic pressure filling, poor sealing performance, and large difficulty in filling Pressure and other problems, to achieve the effect of high inflation pressure, convenient observation and reading, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

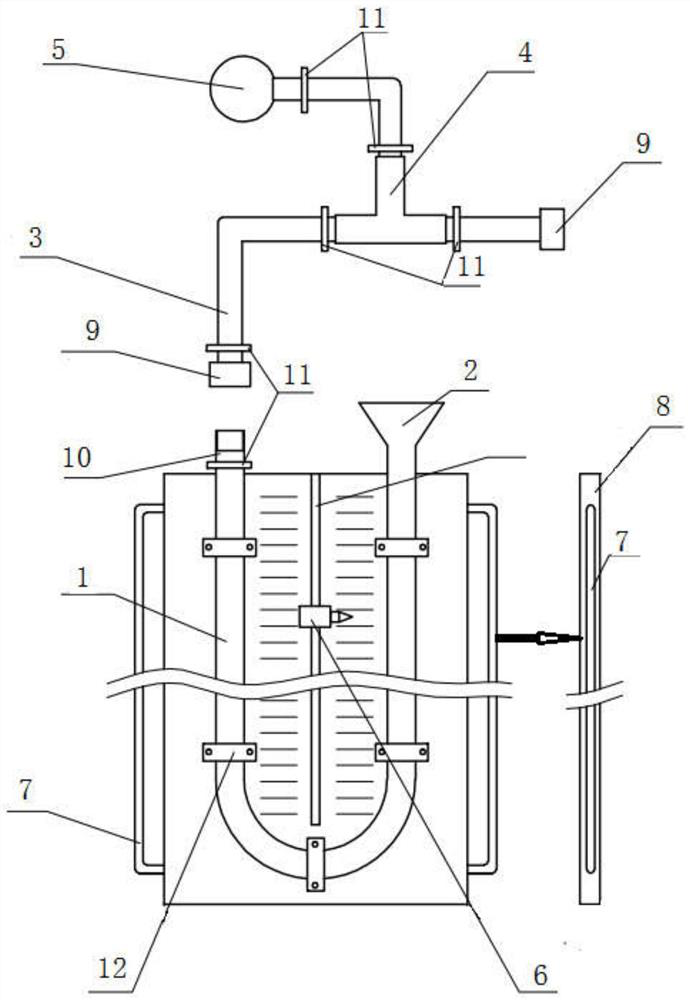

[0032] like figure 1 As shown, the present invention is a gas pipeline seal detection device that can be pressurized and has a scale. Connect the hose 3, the other end of the hose 3 is connected to the detection port of the gas pipeline system to be tested through a quick connector, the hose 3 is provided with a tee 4, and the bypass connection of the tee 4 is used for the U-shaped transparent hose water column meter 1 and An inflatable balloon 5 inflated by the gas pipeline system to be tested, and a movable scale 6 capable of marking the initial liquid level is arranged on the middle beam between the transparent hoses on both sides of the U-shaped transparent hose water column meter 1 .

[0033] As a preferred embodiment of the present invention, it also includes a bracket 7 with a scale plate 8 for supporting and fixing the U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com