Kr-85 sealed radioactive source vacuum inflation system and inflation method

An inflatable system and radioactive source technology, applied in the directions of radioactive source, container filling method, container discharge method, etc., can solve the problems of prolonged production operation time, large pipeline volume, poor inflatable pressure accuracy, etc., and improve operation safety. , Simplify the production process and improve the effect of inflation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

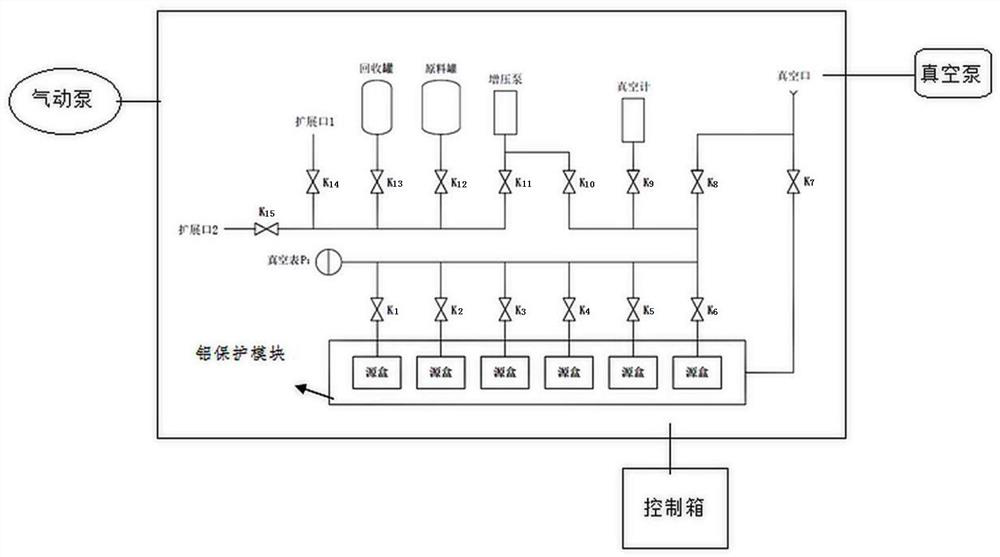

[0086] This embodiment is an inverted Kr-85 raw material. The Kr-85 raw material gas is in a hemispherical tank with a manual valve, the inner cavity of the sphere is 300mL, and the Kr-85 raw material gas pressure is 110kPa.

[0087] The connection between the hemispherical tank and the valve K14 is realized through the metal pipe and ferrule. There is no raw material in the raw material tank in the vacuum inflation system, and the internal absolute pressure is 10Pa.

[0088] Follow the steps below to implement:

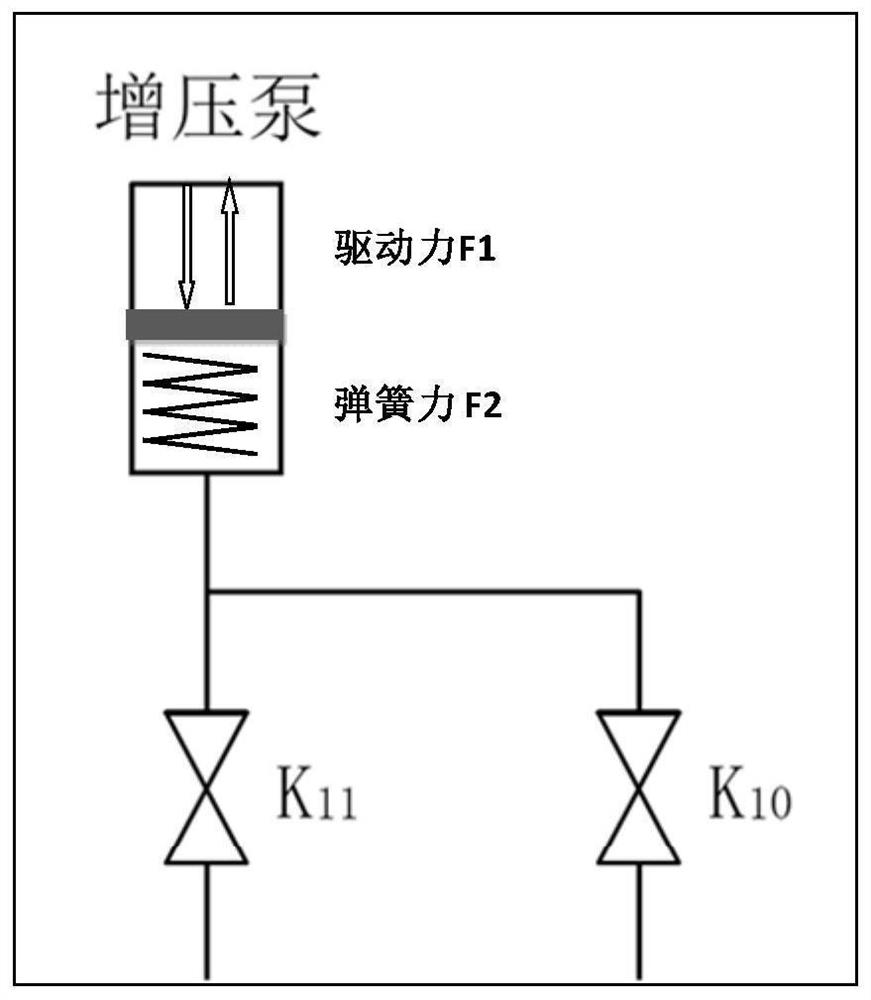

[0089] Turn on the vacuum pump, turn on K8, K9, K10, K11, and K14, evacuate the gas in the main pipeline until the vacuum gauge shows 1Pa, and then turn off K8, K9.

[0090] Soak the recovery canister and radioactive source canister in liquid nitrogen for 1 minute.

[0091] Open the manual valve on the hemispherical tank to release the Kr-85 raw material gas so that the raw material gas fills the pipeline.

[0092] Open K12 to make most of the Kr-85 gas in the pi...

Embodiment 2

[0096] This example is the inflation of a 150 kPa source box.

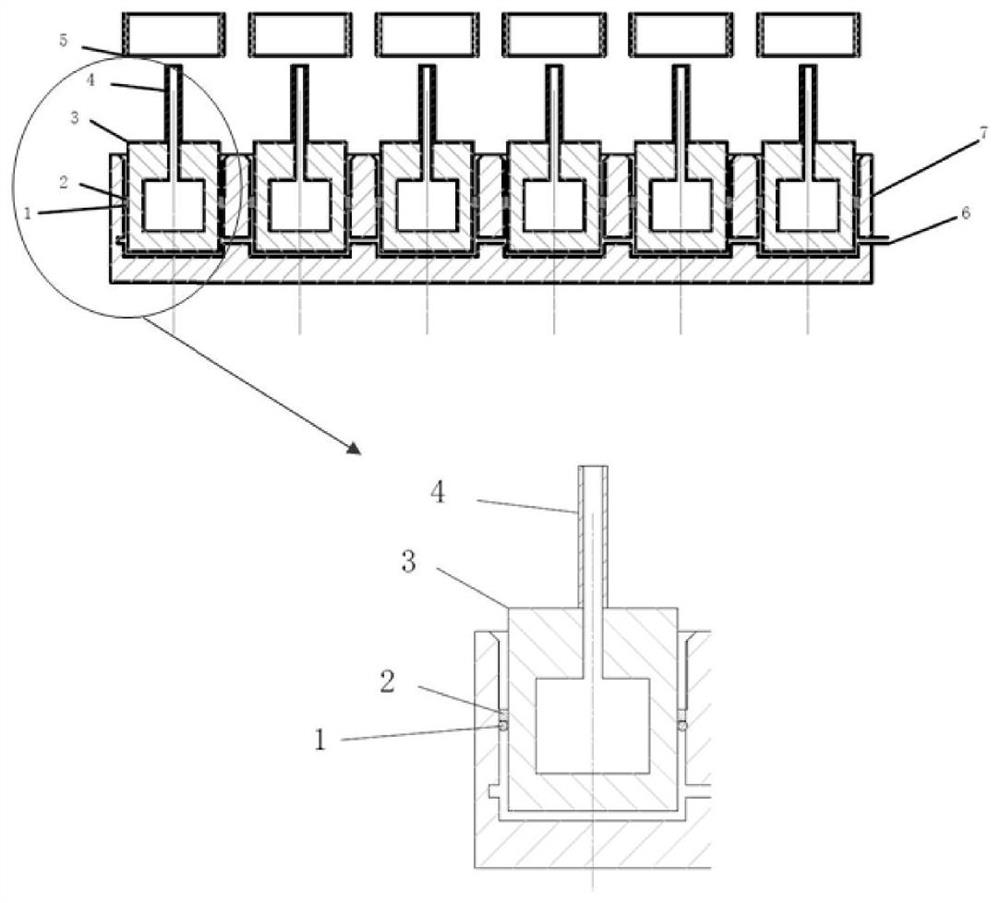

[0097] Put the source box into the aluminum protection module, tighten the threaded pressure head with a special wrench, raise the protection module, and tighten the double ferrule thread to connect the K1-K6 valve.

[0098] Turn on the vacuum pump, turn on K8, K9, K10, and K11, evacuate the gas in the main pipeline until the vacuum gauge reads 1 Pa, and then turn off K10, K11.

[0099] Open the pneumatic valve K7, and the aluminum protection module is evacuated.

[0100] Turn on K1-K6 in turn, and vacuum each source box until the vacuum gauge is 1Pa. Then close K1-K6 and K8. After 1 minute, open K1. If the vacuum gauge rises more than 20Pa after opening the valve, it is judged that the source box connected to K1 is leaking. Open K2-K6 in turn to check the remaining 5 source boxes. leak. Then close the K9 valve.

[0101] Open the K12 valve to release the raw material gas, and then open the K11, K10, K8, K1-K6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com