A reinforced ultra-high-speed, high-density, and high-reliability connector

An ultra-high-speed, high-density technology, applied in the direction of connection, two-part connection device, and components of the connection device, which can solve the problems of signal transmission failure, unstable product performance, and high cost, and achieve the effect of improving the crosstalk problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

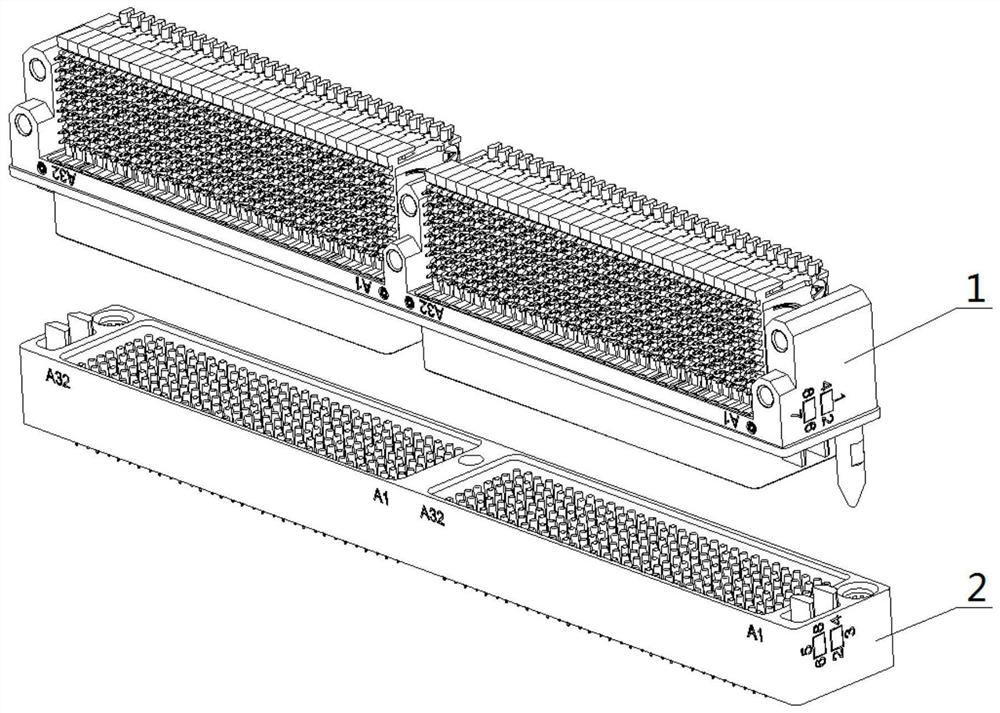

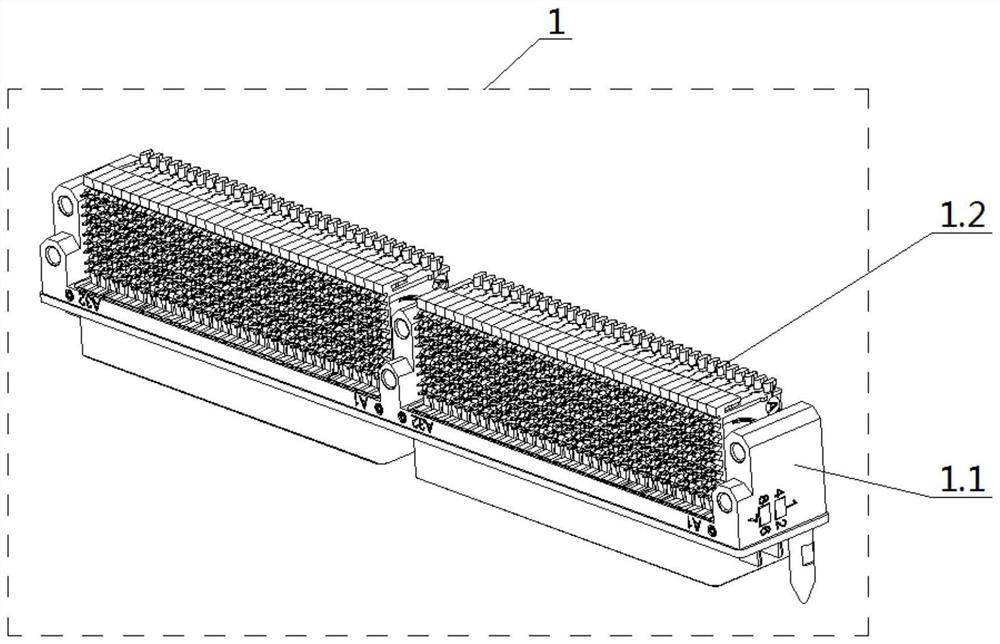

[0056] A reinforced ultra-high-speed, high-density, and high-reliability connector, including a plug 1, a socket 2, and the plug 1 and the socket 2 are mated to form a complete ultra-high-speed, high-density, and high-reliability connector;

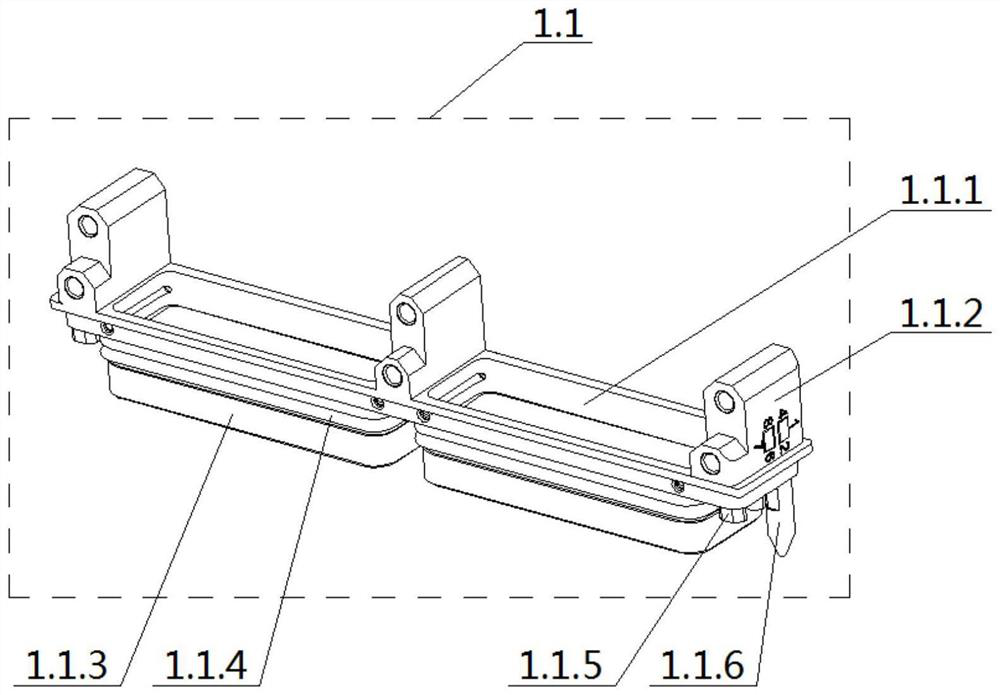

[0057] The plug 1 includes a plug housing 1.1 and a plug module 1.2; the plug housing 1.1 is in the shape of a rectangular plate, which is provided with several through-hole plug module mounting holes 1.1.1; the upper plate is provided with several plug fixing ears 1.1 .2, the plug fixing ear 1.1.2 is provided with a fixing hole; the lower plate is provided with a plug guide frame 1.1.3 around the plug module installation hole 1.1.1, and a sealing ring is provided on the outer peripheral surface of the plug guide fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com