Ultrahigh-speed high-density high-reliability connector socket assembly structure

A connector socket and component structure technology, which is applied to the components, connections, and fixed connections of connecting devices, can solve the problems of unstable impedance characteristics, loose sockets, and bending damage of sockets, and achieve good impedance characteristics consistency. , The effect of eliminating radial clearance and eliminating axial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

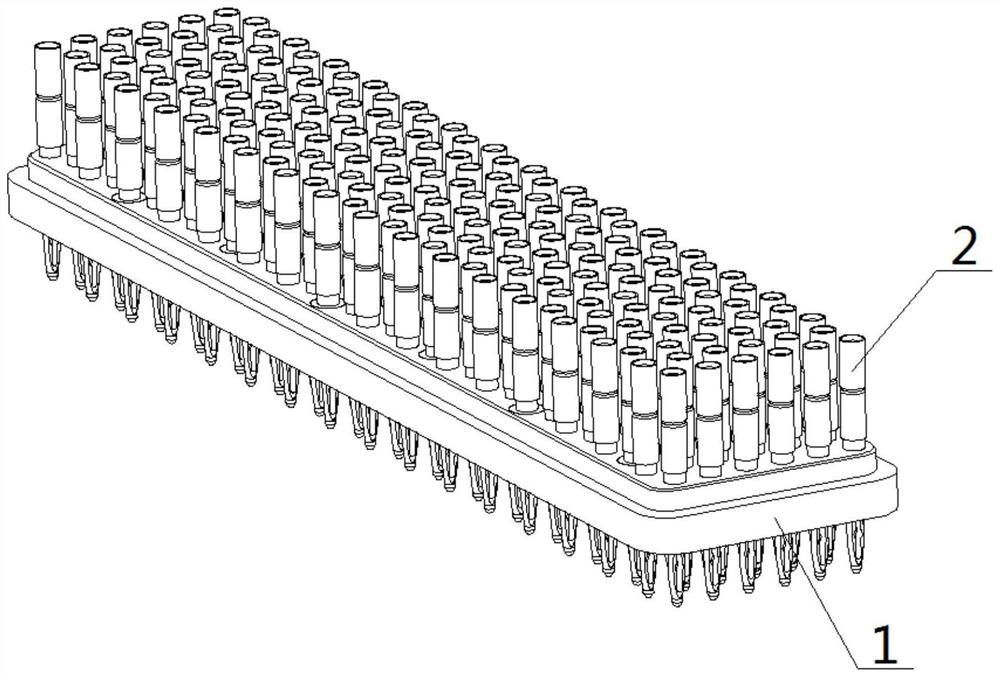

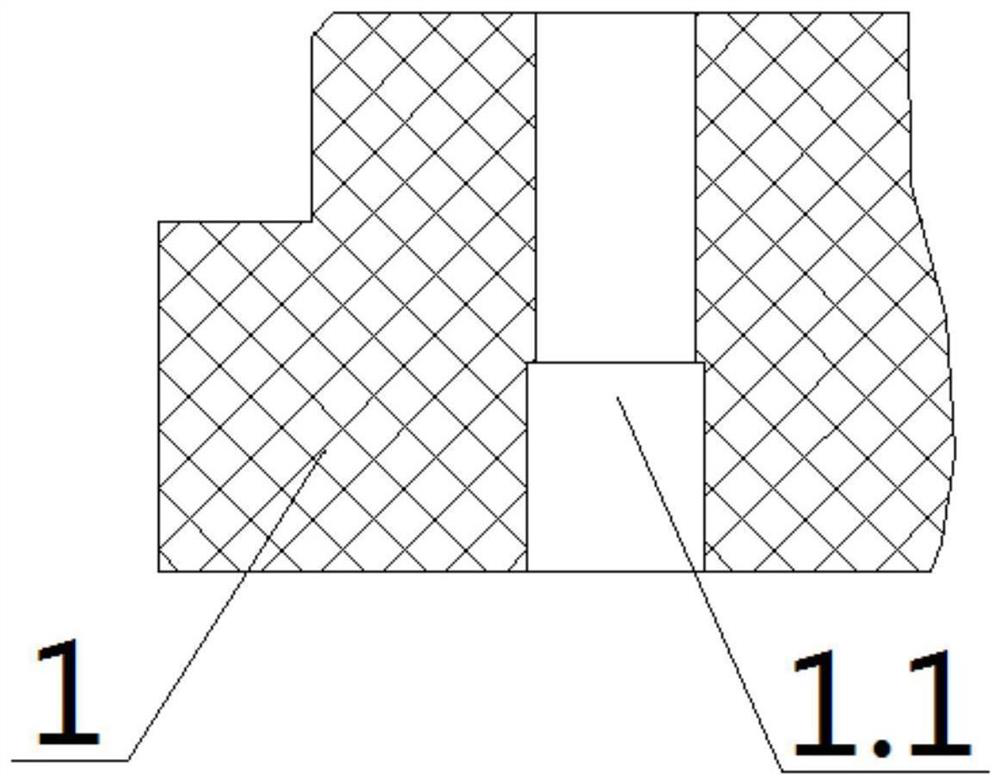

[0019] An ultra-high-speed, high-density, high-reliability connector socket assembly structure, including a socket body 1 and a socket 2; the socket body 1 is in the shape of a rectangular block, and its upper and lower surfaces are provided with a number of through socket installation holes 1.1, and the socket is installed The hole 1.1 is a stepped hole, and its lower aperture is larger than the upper aperture; the socket 2 is in the shape of a thin stepped shaft, which is fixedly arranged in the socket installation hole 1.1;

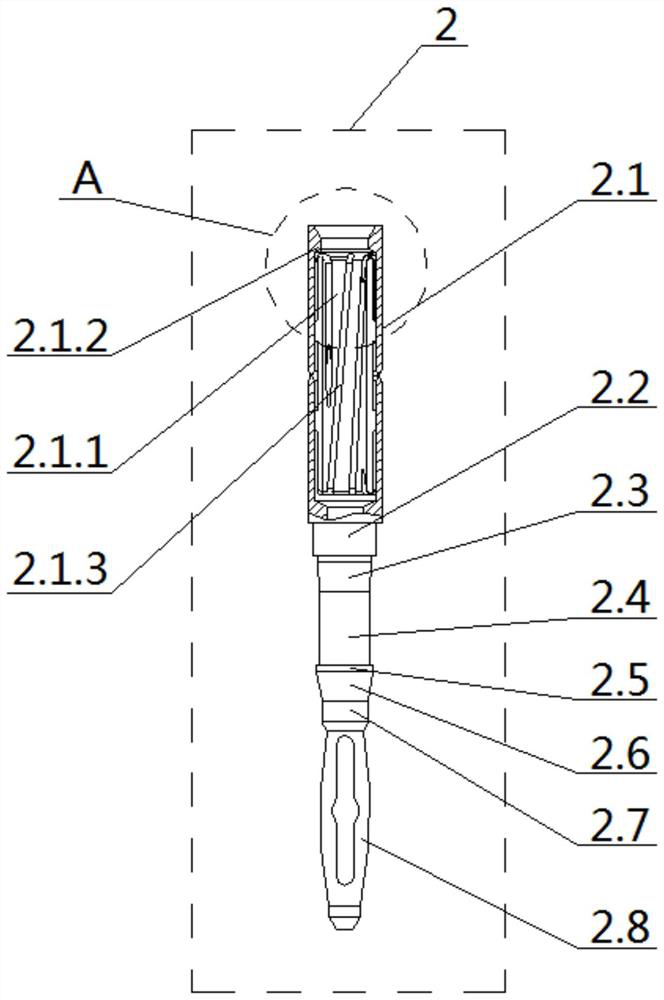

[0020] The socket 2 is sequentially provided with a socket tail section 2.1, a transition section A2.2, an anti-loosening cone section 2.3, a transition section B2.4, an anti-stripping section 2.5, an expansion cone section 2.6, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com