PMOS power tube grid clamping driving module, driving circuit and switching power supply

A drive module and gate drive technology, applied in high-efficiency power electronic conversion, output power conversion device, DC power input conversion to DC power output, etc. The problem of effective clamping between the pole and the source can achieve the effect of reducing the conduction loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

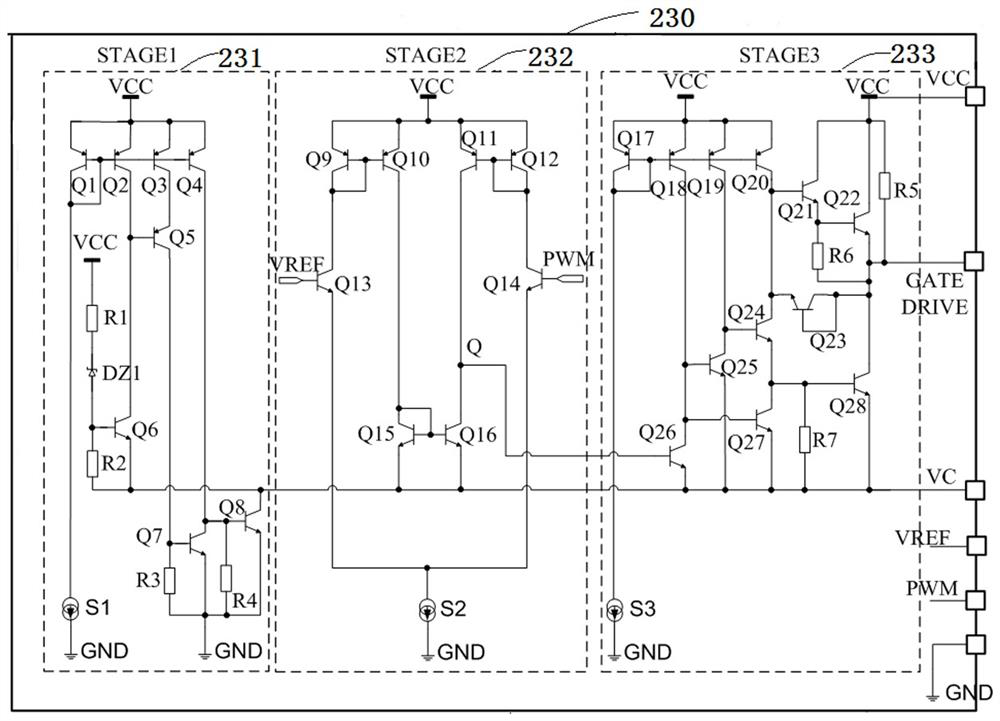

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with specific embodiments.

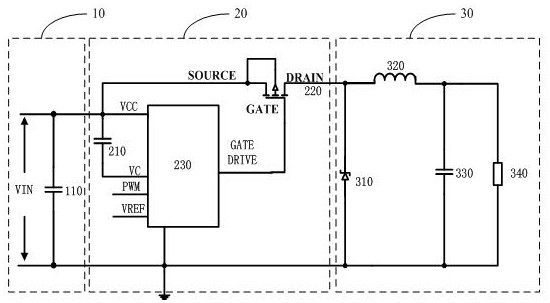

[0029] The embodiment of the present invention firstly provides a switching power supply, please refer to figure 1 , including a power supply circuit 10 , an output circuit 30 and a switching power supply driving circuit 20 . One end of the switching power supply driving circuit 20 is connected to the power supply circuit 10 , and the other end of the switching power supply driving circuit 20 is connected to the output circuit 30 .

[0030] In this embodiment, the power supply circuit 10 includes an input DC power supply VIN and an input filter capacitor 110 connected in parallel.

[0031] The output circuit 30 includes a Schottky diode 310, a power inductor 320, an output filter capacitor 330, and a load 340. The cathode of the Schottky diode 310 is connected to the drain of the PMOS power tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com