Broadband motor

A motor, broadband technology, applied in the field of broadband motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

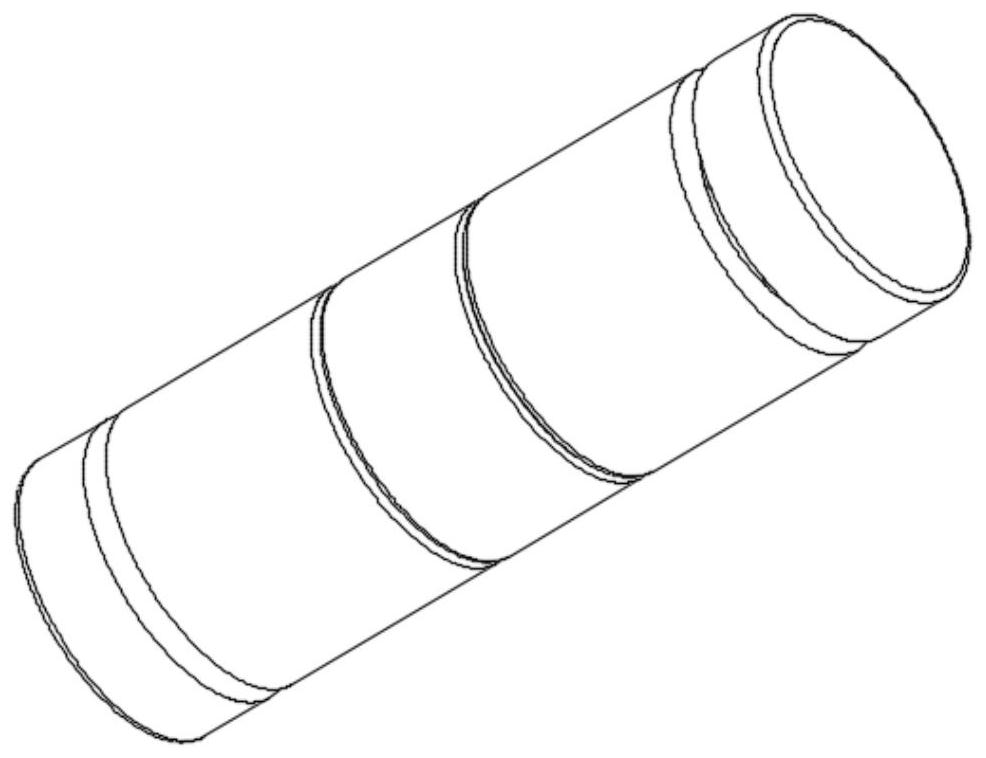

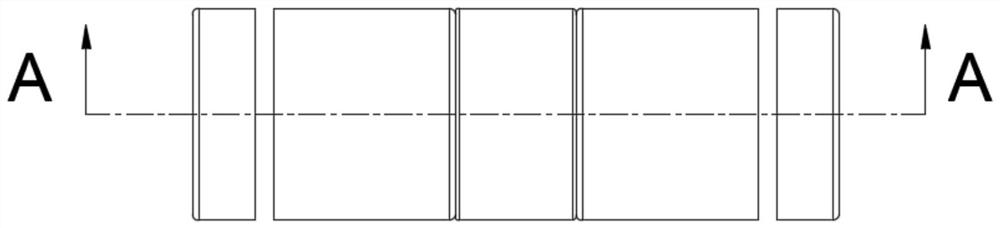

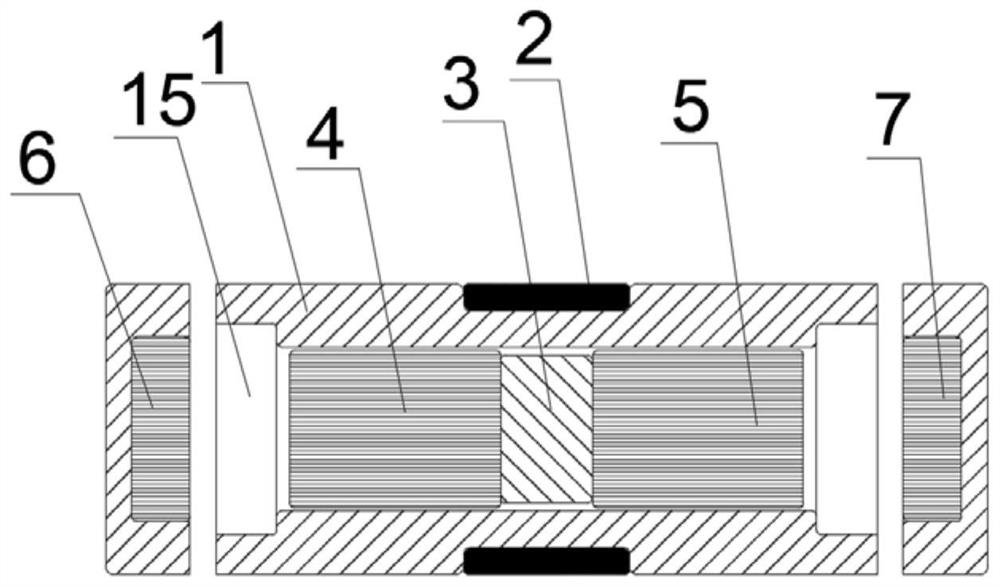

[0094] Example 1: Semi-maglev circular wide-frequency response motor

[0095] like Figure 1-2 , as shown in 4-6 and 3a, the present invention provides a wide-frequency response motor, including a housing 1, a coil 2, a magnetic assembly and a connecting piece 3, the magnetic assembly is arranged in the housing, wherein the magnetic assembly includes a first A magnetic part 4, a second magnetic part 5, a third magnetic part 6 and a fourth magnetic part 7, the left and right sides of the connecting part 3 are respectively provided with a first magnetic part 4 and a second magnetic part 5, wherein the The connecting piece 3 is closely connected with the first magnetic piece 4 and the second magnetic piece 5, and the connecting piece 3, the first magnetic piece 4 and the second magnetic piece 5 constitute a vibrator assembly; the first magnetic piece 4 is far away from the connecting piece 3 One side of the second magnetic part 5 is provided with a third magnetic part 6, and the...

Embodiment 2

[0104] Example 2: The other half of the maglev circular wide-frequency response motor

[0105] The difference between Embodiment 2 and Embodiment 1 is only that the magnetic force of the third magnetic part is different from that of the fourth magnetic part, such as Figure 3b As shown, the distance between the first magnetic piece and the third magnetic piece provided in this embodiment is not equal to the distance between the second magnetic piece and the fourth magnetic piece, although it is not a symmetrical force balance, but in the left-right direction The magnetic force balance is also achieved, so that the vibrator assembly is suspended in the inner cavity of the stator.

Embodiment 3

[0106] Example 3: Magnetic Suspension Circular Wide-Frequency Response Motor

[0107] like Figure 7 As shown, this embodiment provides a wide-frequency response motor, including a housing 1, a coil 2, a magnetic assembly and a connecting piece 3, the magnetic assembly is arranged inside the housing, and the coil 2 is sleeved outside the housing 1.

[0108] Wherein, the magnetic assembly includes a first magnetic piece 4, a second magnetic piece 5, a third magnetic piece 6, a fourth magnetic piece 7, a fifth magnetic piece 8 and a sixth magnetic piece 9, and the connecting piece 3 has two left and right sides. The first magnetic part 4 and the second magnetic part 5 are respectively arranged on the side, wherein, the connecting part 3 is closely connected with the first magnetic part 4 and the second magnetic part 5, and the connecting part 3, the first magnetic part 4 and the The second magnetic part 5 constitutes a vibrator assembly; the first magnetic part 4 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com