Hard start, soft start and variable frequency start integrated switching module

A technology of variable frequency starting and switching modules, which is applied to motor generators/starters, starters of single multi-phase induction motors, etc., can solve the problems of complicated wiring, burden on wiring installation personnel, complicated equipment connection control, etc., and achieve work safety. Reliable, stable, and the effect of meeting switching needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

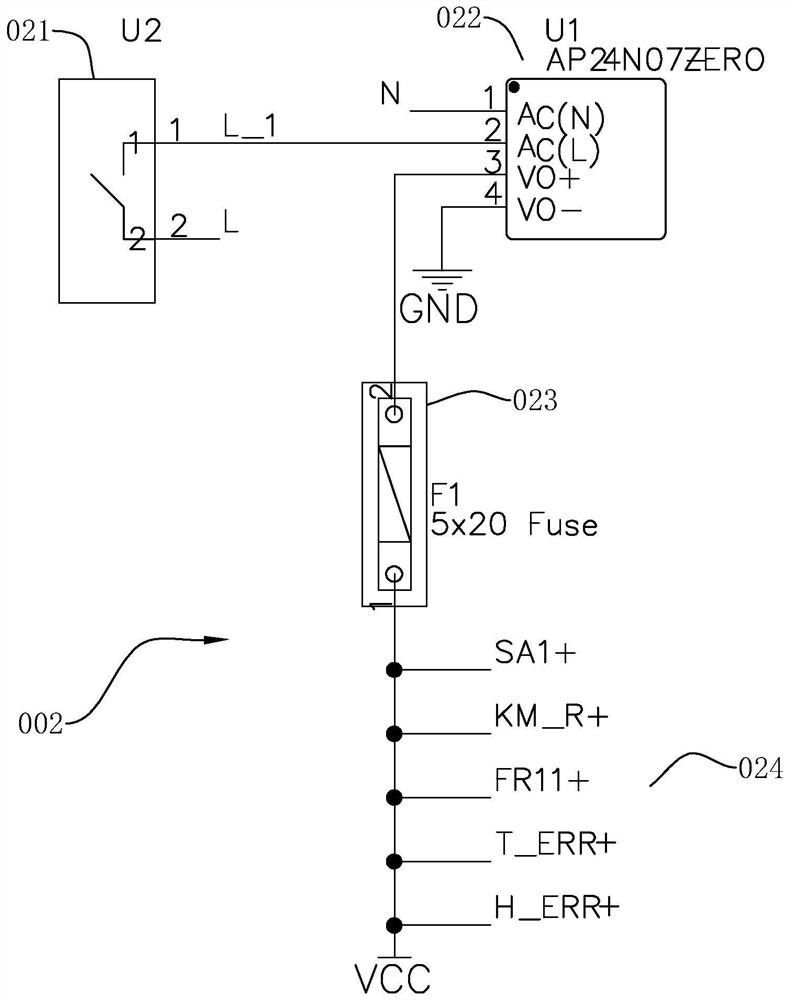

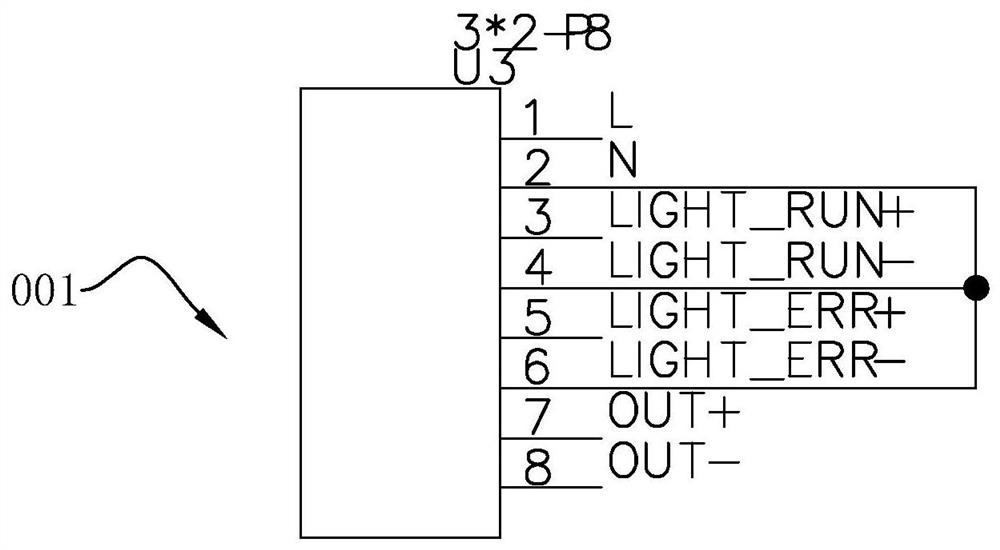

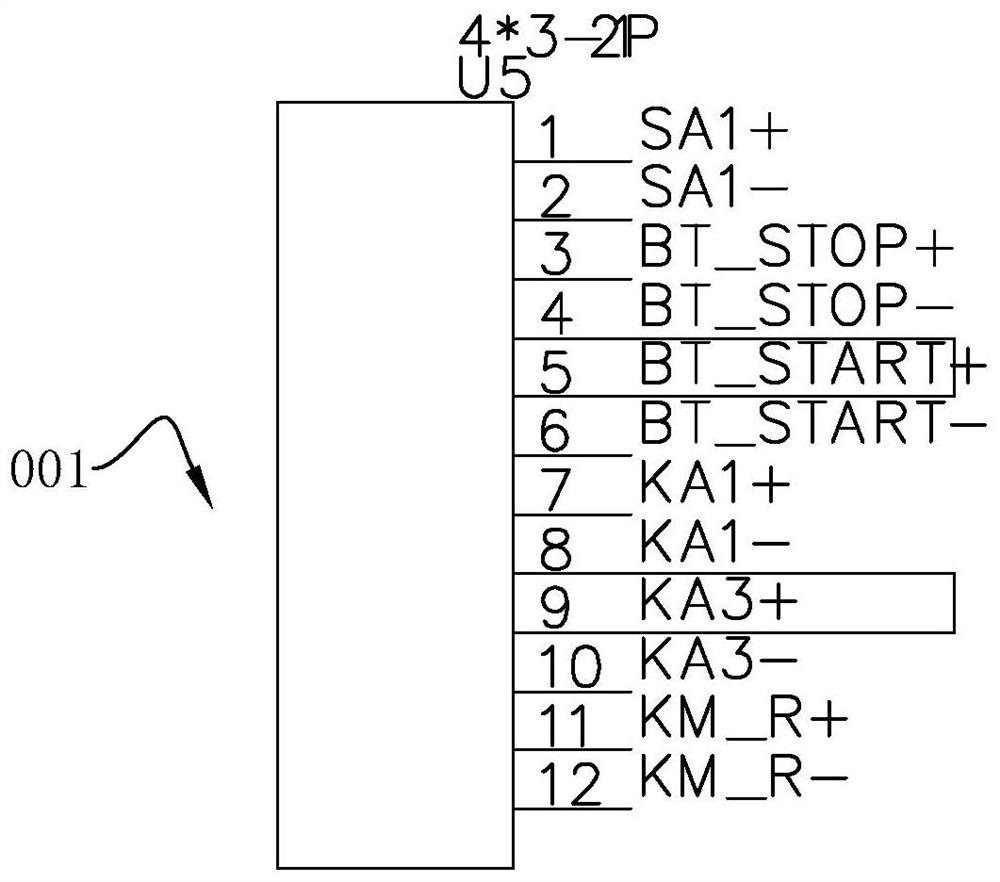

[0033] refer to Figure 1 to Figure 9 , can be used as an embodiment, a hard start, soft start, frequency conversion start integrated switching module, combined with figure 1 , figure 2 , image 3 and Figure 4 , including a signal connection port 001, a power conversion module 002, an indicator light module 003, and a relay module 004. There are three signal connection ports 001, one with 8 terminals and two with 12 terminals. The signal names on the interface ends of the signal lines are defined by popular conventional naming. L means live line, N means neutral line, from figure 2 At the beginning, it is the positive signal of the running light, the negative signal of the running light, the positive signal of the fault light, the negative signal of the fault light, the positive output, the negative output, image 3 Middle, Device Positive, Device Negative, Stop Positive, Stop Negative, Start Positive, Start Negative, Repeater Coil Positive, Repeater Coil Negative, Th...

Embodiment 2

[0041] Based on the structural foundation of embodiment 1, refer to Figure 10 As shown, it also includes a high-voltage isolating switch 051, a high-voltage circuit breaker 052, a voltage and current transformer 053, an intelligent electric energy detection module 054, a controller 055, a graded frequency converter 056, a power conversion circuit 057, a filter reactor 058, and a variable reactance Inverter 059, capacitor bank 060.

[0042] The three-phase power supply is sequentially connected to a high-voltage isolation switch 051 and a high-voltage circuit breaker 052. The output end of the high-voltage circuit breaker 052 is connected to an external motor device through the second contact switch, and the variable reactance converter 059 is also connected in series through the first contact switch. On the external motor equipment, the filter reactor 058 is also connected to the external motor equipment through the third contact switch, and the voltage and current transforme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com