Active and passive dual-purpose liquid cooling radiator and manufacturing method thereof

A radiator and liquid cooling technology, used in cooling/ventilation/heating renovation, electrical equipment structural parts, electrical components, etc., can solve the problem of heat dissipation that cannot be solved, liquid cooling products cannot achieve efficient heat dissipation, and affect the normal operation of communication equipment and other problems, to achieve the effect of good heat dissipation, normal use, and efficient vehicle cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

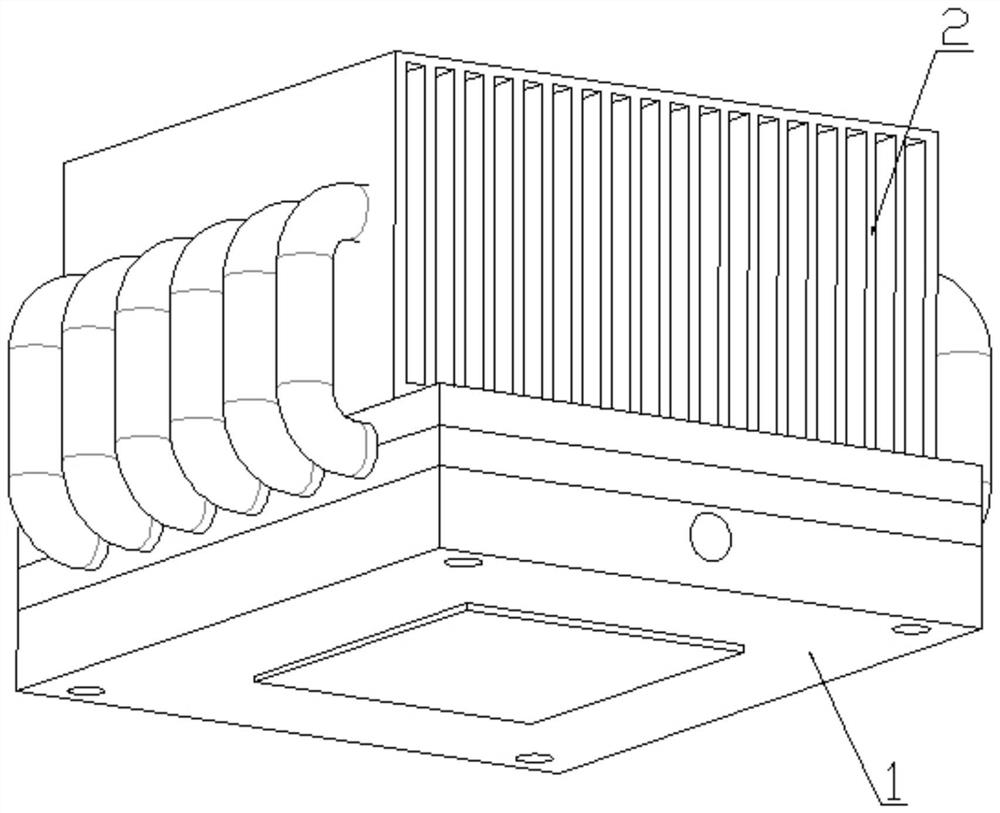

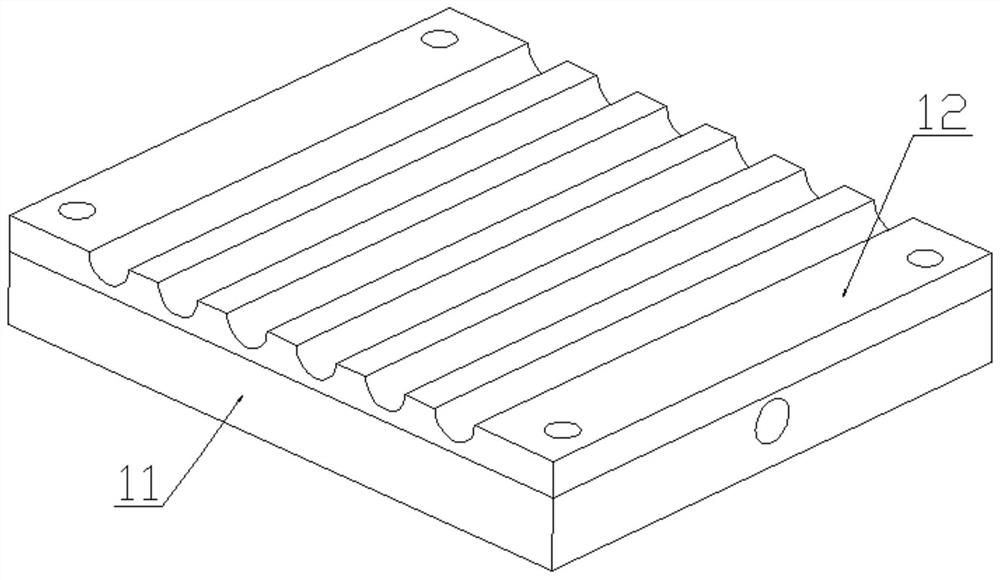

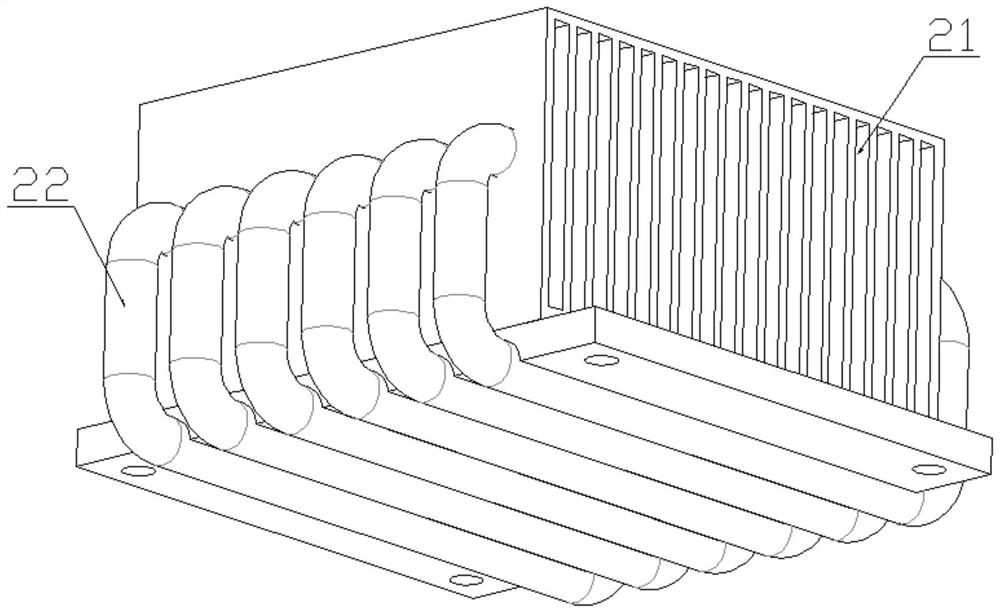

[0026] An active and passive dual-purpose liquid cooling radiator, such as Figure 1-3 As shown, it is used for heat dissipation of the chip, including a liquid cooling base 1 and a heat pipe heat sink 2 . The liquid cooling base 1 is composed of a base plate 11 and a cover plate 12 , and a cooling water tank 111 is provided on the base plate 11 . In order to improve heat dissipation efficiency and reduce carrying weight, the base plate 11 and the cover plate 12 are made of 6063 aluminum alloy. Such as Figure 4 As shown, the cooling water tank 111 includes a plurality of branch water tanks arranged in parallel, and the two ends of the mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com