Waste gas purification pipeline for garbage treatment

A technology for waste gas purification and garbage treatment, which is applied in chemical instruments and methods, the use of liquid separation agents, and the separation of dispersed particles. Avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

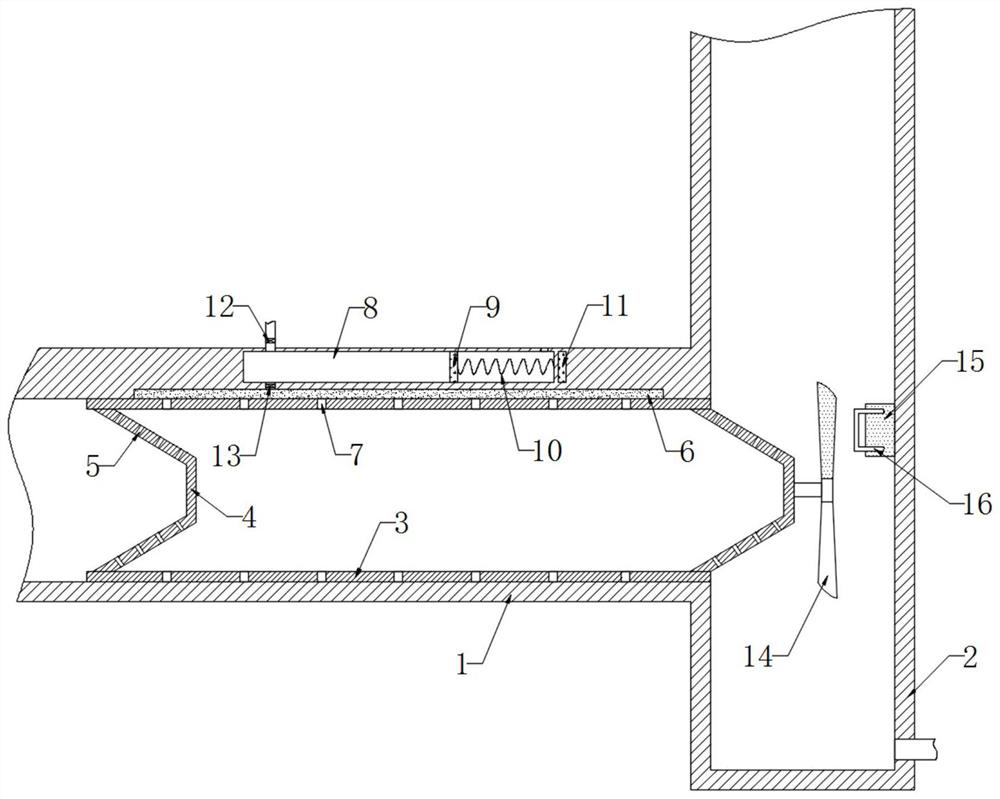

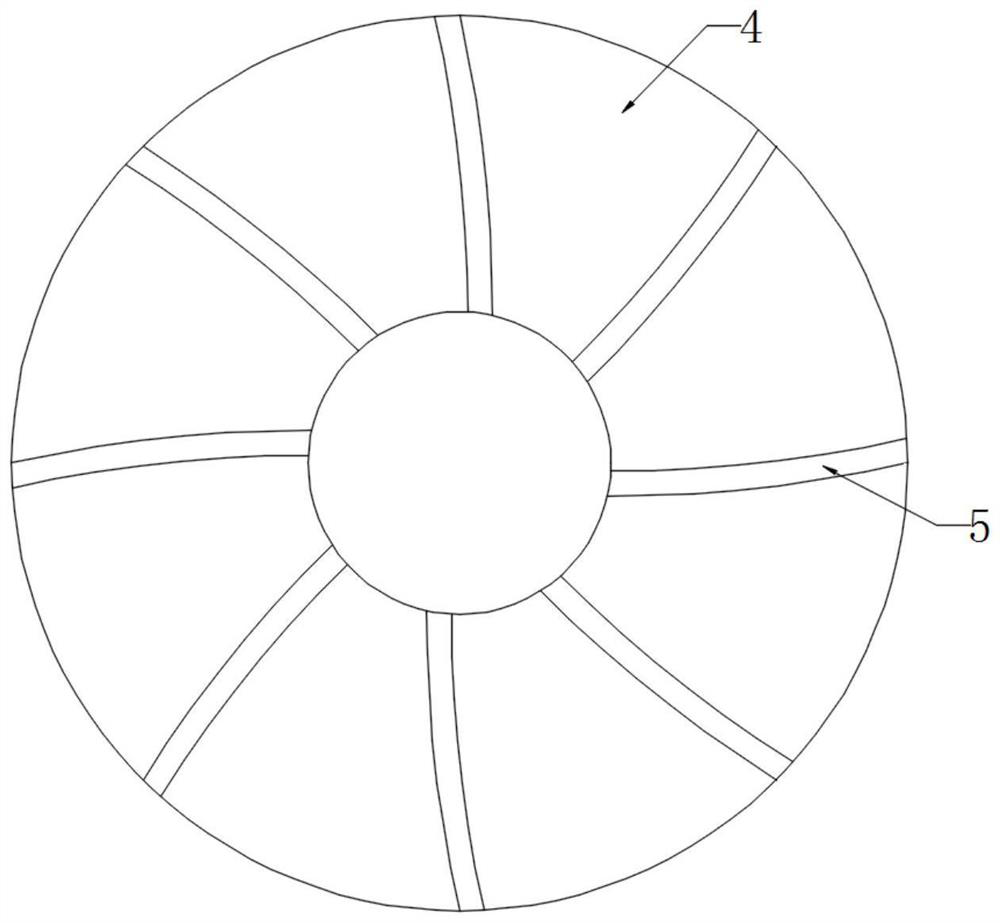

[0022] refer to Figure 1-2 , a waste gas purification pipeline for waste disposal, comprising a pipe body 1, the side wall of the pipe body 1 is fixedly connected with an exhaust pipe 2, the inner wall of the pipe body 1 is rotatably connected with a ring 3, and the inner wall of the ring 3 is symmetrically fixedly connected with a tapered pipe 4. The conical tube 4 is arranged in a hollow conical shape, and the side wall of the conical tube 4 is provided with a plurality of exhaust channels 5 uniformly distributed in the circumferential direction. Further, the plurality of exhaust channels 5 are curved and have the same direction of rotation. When When the exhaust gas flows in the pipe body, the rotational force generated by the gas flowing in the exhaust channel 5 is superimposed on each other, so that the conical pipe 4 rotates under the action of the air flow. The upper end of the pipe body 1 is embedded with a liquid absorbent cotton 6, and the inner wall of the ring 3 A...

Embodiment 2

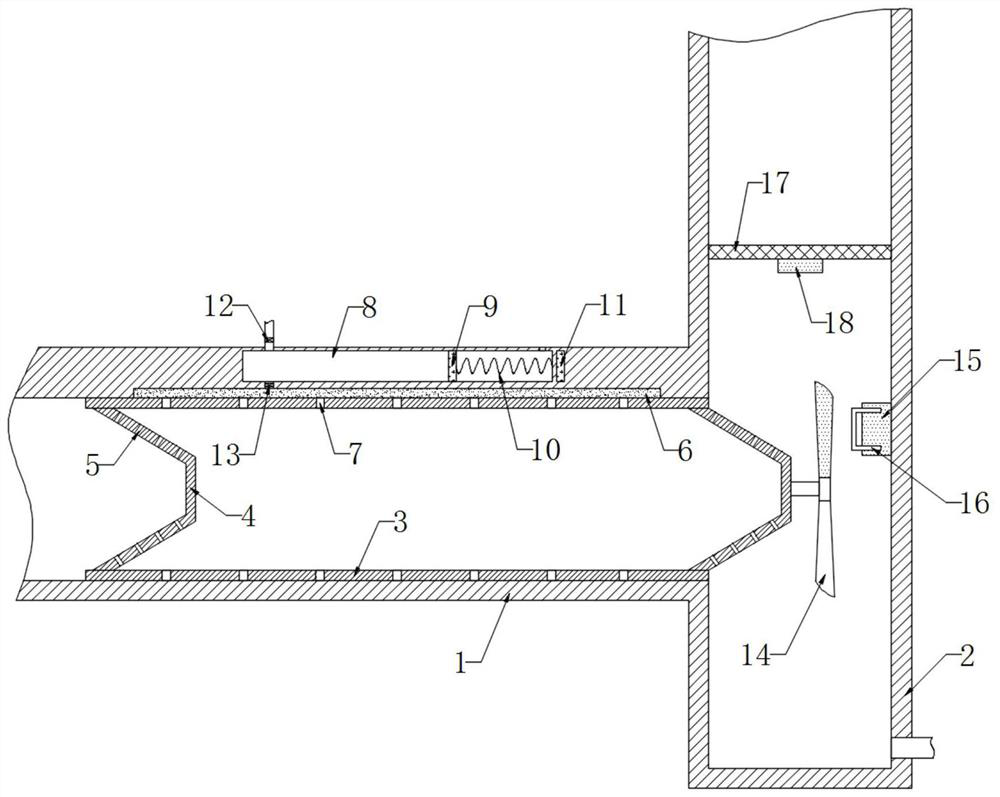

[0029] refer to image 3 , different from the first embodiment, the inner wall of the exhaust pipe 2 is fixedly connected with an elastic filter 17, and the lower end of the elastic filter 17 is fixedly connected with an iron block 18.

[0030] In this embodiment, when the air bubbles absorb harmful gas and dust and flow out from the exhaust duct 5 into the exhaust pipe 2, part of the air bubbles will flow upward in the exhaust pipe 2 along with the flow of the exhaust gas. When in contact, the air bubbles burst, and then the elastic filter 17 blocks the air bubbles to prevent the air bubbles from escaping into the air and causing secondary pollution. The net 17 shakes continuously to shake off the dust and water droplets accumulated on the elastic filter screen 17, so that the elastic filter screen 17 maintains good gas circulation and will not affect the discharge of exhaust gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com