Rotating structure of part detecting device for electronic product design

A technology for detecting devices and electronic products, which is applied to measuring devices, parts of electrical measuring instruments, and cleaning methods using tools, etc. Less frequent cleaning, less operation, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

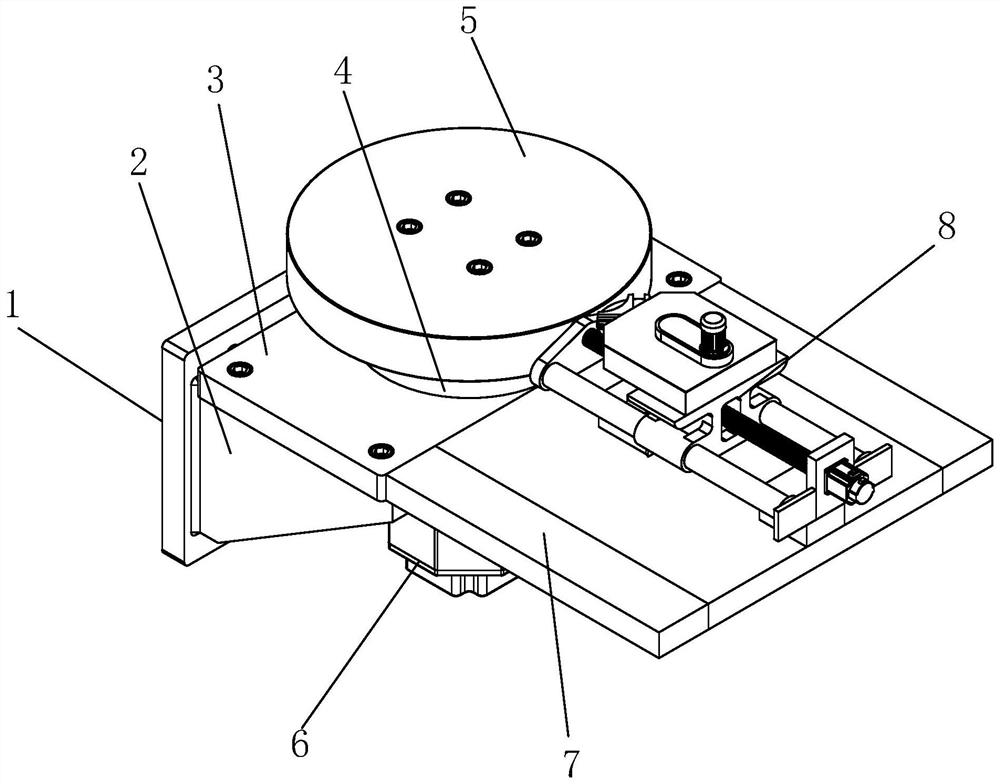

[0031] See figure 1 , The present invention provides a rotating structure of a part detection device for electronic product design through improvement, including a support plate 1, the right side of the support plate 1 is fixed to a fixing frame 2, and the top of the fixing frame 2 is fixed to the top plate 3 by bolts, The top middle of the top plate 3 is provided with a fixing base 4, the top of the fixing base 4 is equipped with a turntable 5, the bottom of the top plate 3 is provided with a first motor 6, and the top output shaft of the first motor 6 sequentially penetrates the top plate 3 and the top of the fixing base 4 to connect with the turntable 5. , A side plate 7 is installed on the right side of the top plate 3, and an auxiliary cleaning device 8 is installed on the top of the side plate 7.

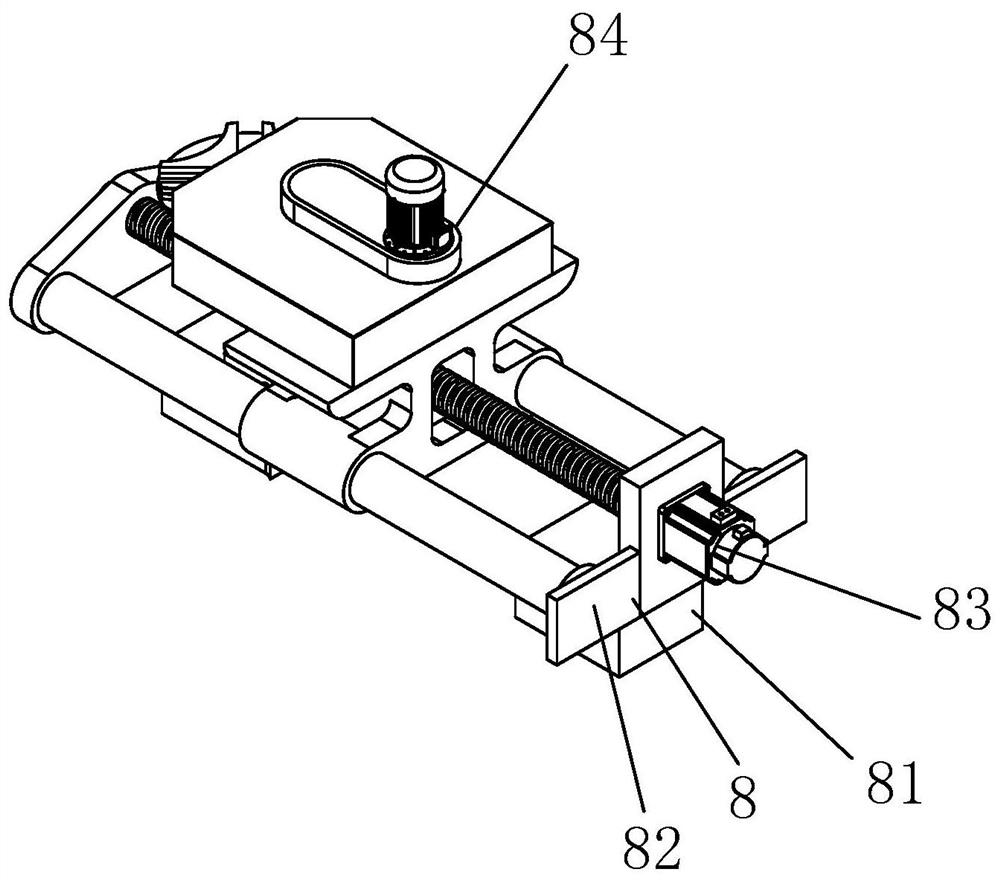

[0032] See figure 2 , The present invention provides a rotating structure of a part detection device for designing electronic products by improving. The auxiliary cleaning device...

Embodiment 2

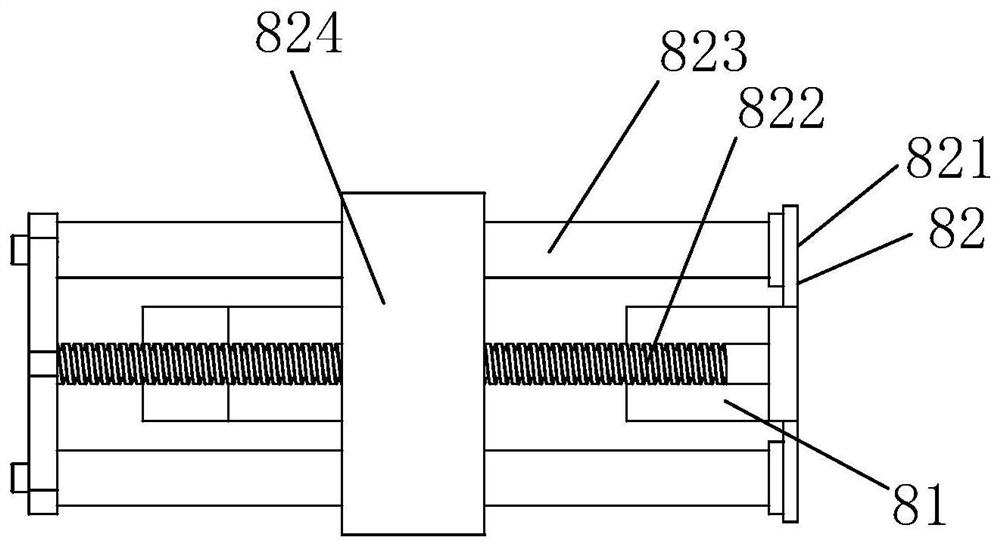

[0039] The present invention provides a rotating structure of a component detection device for electronic product design through improvement. The outer diameter surface of the guide rod 823 is smooth, and the outer diameter of the guide rod 823 is larger than the outer diameter of the threaded rod 822, which effectively realizes stable Guide; the back of the protective shell 841 is provided with a sealing cover, and the protective shell 841 is fixed with the sealing cover by bolts, which is convenient for inspection and maintenance in the protective shell 841; the four ends of the outer diameter surface of the driving wheel 8443 are concave arc shapes, and drive The four ends of the outer diameter surface of the wheel 8443 are in contact with the surface of the rotating wheel 8441.

[0040] The present invention provides a rotating structure of a component detection device for electronic product design through improvement, and its working principle is as follows;

[0041] First, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com