MPR fireproof and thermal insulation template production line

A technology for fire protection and heat preservation and production line, which is applied in the direction of metal processing, etc., and can solve the problems of easy damage of plates and affecting heat preservation performance, etc., and achieve the effects of flexible use, improved work efficiency, and improved laying efficiency and laying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

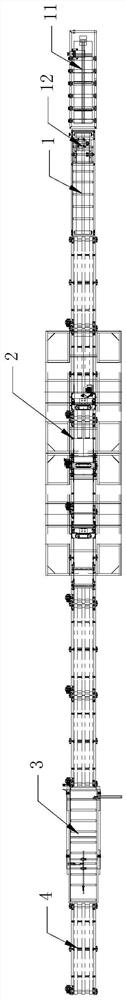

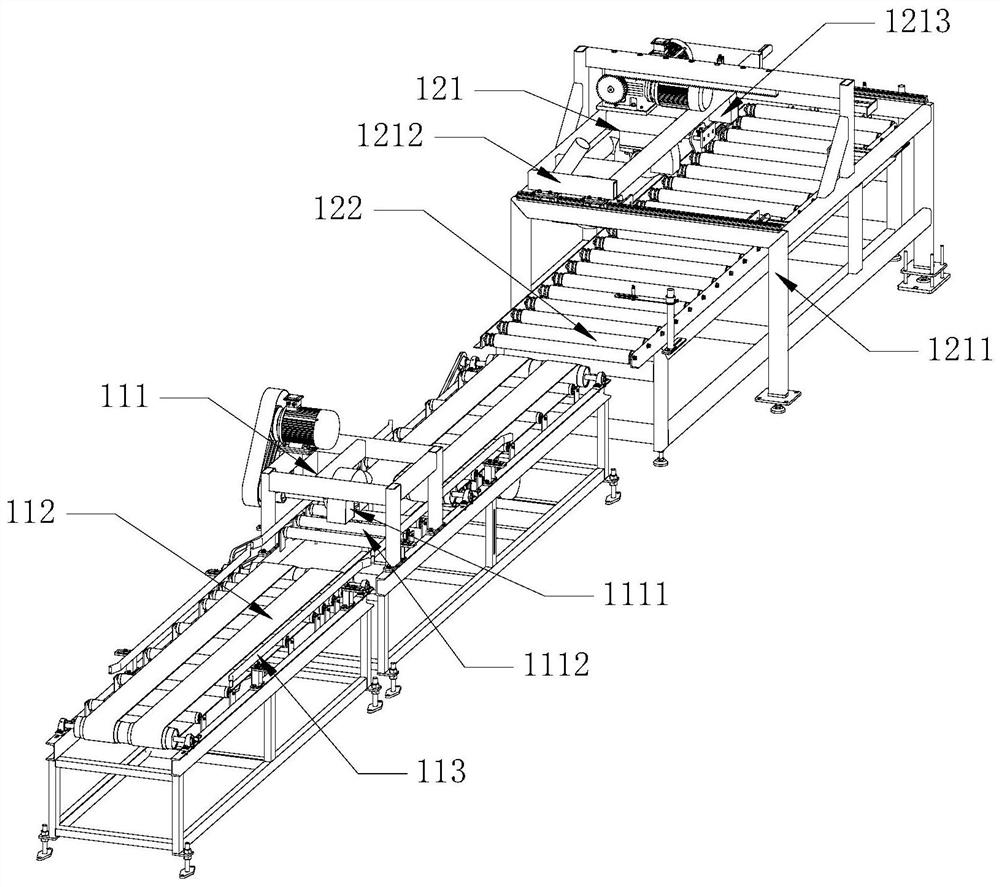

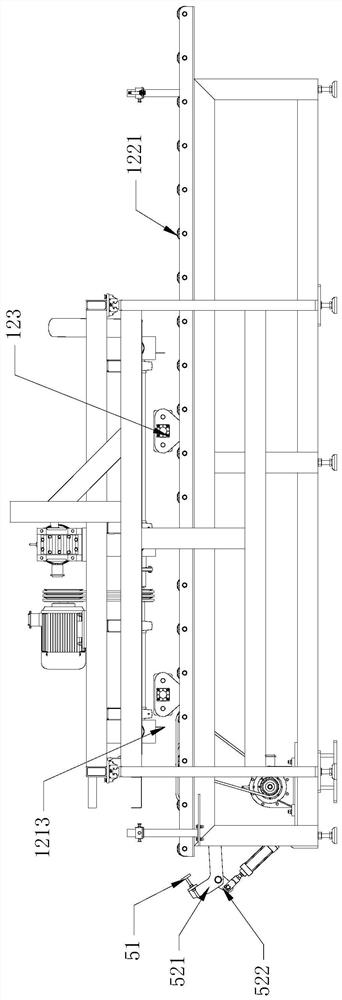

[0050] A kind of MPR fire-proof and heat-preservation formwork production line in the present embodiment, such as figure 1 As shown, including the conveying line, according to the conveying direction of the conveying line, a slotting mechanism 1, a conveying and laying mechanism 2, a grid cloth cutting mechanism 3 and a discharging mechanism 4 are sequentially arranged on the conveying line; Figure 2-Figure 4 As shown, the slotting mechanism 1 includes a first slotting part 11 for axial slotting of a sheet and a second slotting part 12 for radial slotting of a sheet, and the first slotting part 11 includes a first slotting saw 111 and the first transmission part 112, the first grooving saw 111 erects above the first transmission part 112, the second grooving part 12 includes the second grooving saw 121 and the second transmission part 122, the second grooving part 12 erects Above the second transmission part 122 , the first transmission part 112 is connected with the conveyin...

Embodiment 2

[0061] On the basis of Embodiment 1, the present embodiment 1 specifically describes the structure of the grid cloth cutting machine, as Figure 5-Figure 8 As shown, the grid cloth cutting mechanism 3 includes a third transmission part 31 and a cutting frame 32. The cutting frame 32 is arranged directly above the third transmission part 31. A limiting part 6 and a cutting part 7 are arranged on the cutting frame 32. The transmission direction of the part, the limit part 6 is arranged in front of the cutting part 7;

[0062] The limiting part 6 includes a baffle 61, which is arranged on the end of the cutting frame 32 away from the cutting member 7. When the baffle 61 is in the first position, the baffle 61 is located between the third transmission part 31 and the cutting frame 32. When the plate 61 is in the second position, the baffle plate 61 is located above the cutting frame 32 ; the cutting member 7 includes a cutting knife 71 and a cutting track 72 , and the cutting knif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com