Hybrid power vehicle driving system capable of realizing single-motor two-gear driving

A hybrid vehicle and drive system technology, applied in hybrid vehicles, motor vehicles, power units, etc., can solve problems such as high cost, increase system complexity, and complex structure, and achieve improved ride comfort, simplified control strategies, simplified effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

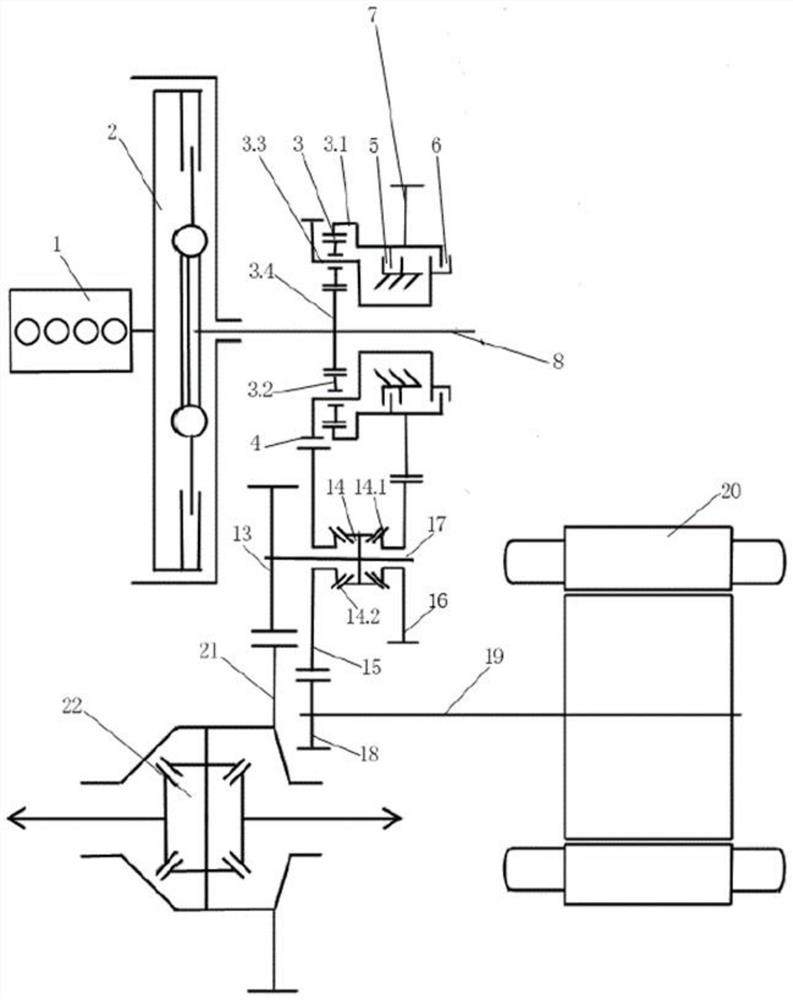

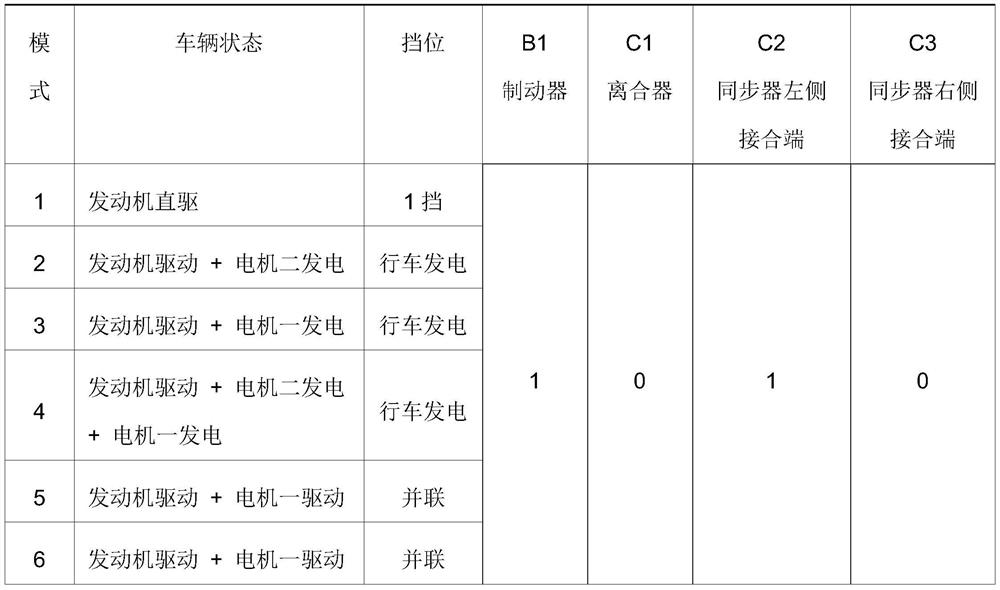

[0027] Such as figure 1 As shown, a hybrid vehicle drive system capable of realizing single-motor two-speed drive includes an engine 1, a motor one 20, a planetary gear mechanism 3 and a synchronizer 14, and the engine 1 is connected to the drive shaft 8 of the engine through a torsional shock absorber 2 The planetary gear mechanism 3 includes a sun gear 3.4 fixedly connected to the drive shaft 8 of the engine, an outer ring gear 3.1 connected to the gearbox housing through a brake 5, a planetary carrier 3.3 connected to the outer ring gear 3.1 through a clutch 6, and located at The planetary gear 3.2 on the planet carrier 3.3 and meshed with the sun gear 3.4 and the outer ring gear 3.1 respectively, the synchronizer 14 is fixedly connected to the intermediate shaft 17, and the left joint end 14.2 of the synchronizer and the right joint end 14.1 of the synchronizer can respectively be connected with the Gear 1 15 and gear 2 16, which are vacantly sleeved on the intermediate sh...

Embodiment 2

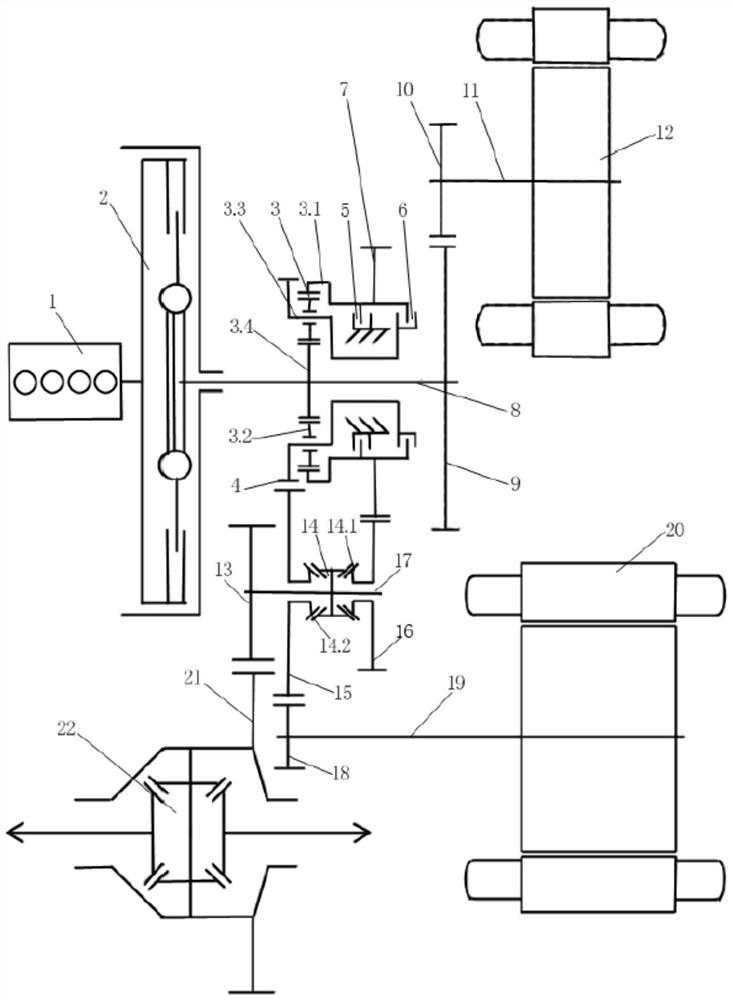

[0050] Such as figure 2 As shown, a hybrid vehicle drive system capable of realizing single-motor two-speed drive includes an engine 1, a motor one 20, a motor two 12, a planetary gear mechanism 3 and a synchronizer 14, and the engine 1 communicates with the engine through a torsional shock absorber 2. The transmission shaft 8 is connected, and the planetary gear mechanism 3 includes a sun gear 3.4 fixedly connected to the transmission shaft 8 of the engine, an outer ring gear 3.1 connected to the gearbox housing through a brake 5, and a planetary carrier connected to the outer ring gear 3.1 through a clutch 6 3.3. The planetary gear 3.2, which is set on the planet carrier 3.3 and meshes with the sun gear 3.4 and the outer ring gear 3.1 respectively, the synchronizer 14 is fixedly connected to the intermediate shaft 17, and the left joint end 14.2 of the synchronizer and the right joint end of the synchronizer 14.1 can be respectively engaged with gear one 15 and gear two 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com