Tape coil positioning and parking method

A tape and coil technology, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as difficulty in positioning tape coils, and achieve the effects of shortening no-load running time, reducing power consumption costs, and improving maintenance efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

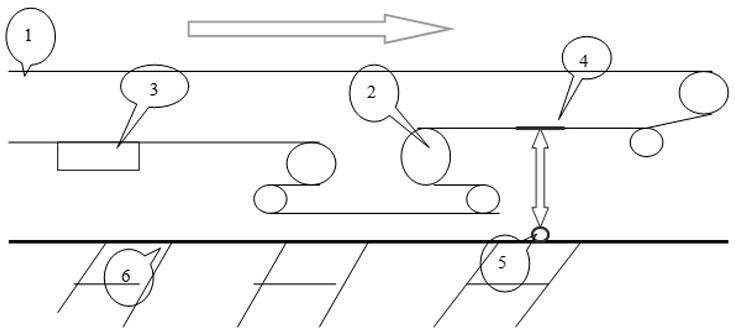

Image

Examples

Embodiment Construction

[0014] Taking the tape coil positioning and parking device installed on the N03 corridor belt conveyor of Taigang Jianshan Iron Mine Inclined Shaft System as an example, the description is as follows:

[0015] In view of the inability to accurately locate the coil of the tape and the fault location, the edge of the tape running is used as the detection point. Every time the electrical tear or fault stops, the underground maintenance personnel will confirm the number of the tape and stick a special reflective sticker (above 1mm) on the side of the tape. The non-transparent object works best) as the receiver of the photoelectric proximity switch, install the reflective photoelectric proximity switch monitoring probe device as the transmitter on the belt frame on the second floor of the east corridor outside the surface cavern, and dynamically monitor the edge of the belt conveyor. The light beam emitted from the transmitter is reflected to the opposite reflector (receiver). When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com