Automatic film re-pasting equipment for slender type workpiece

A kind of automation equipment, slender technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, sheet quality problems, high cost, etc., to reduce the demand for human resources, improve production yield, The effect of ensuring the accuracy of reposting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

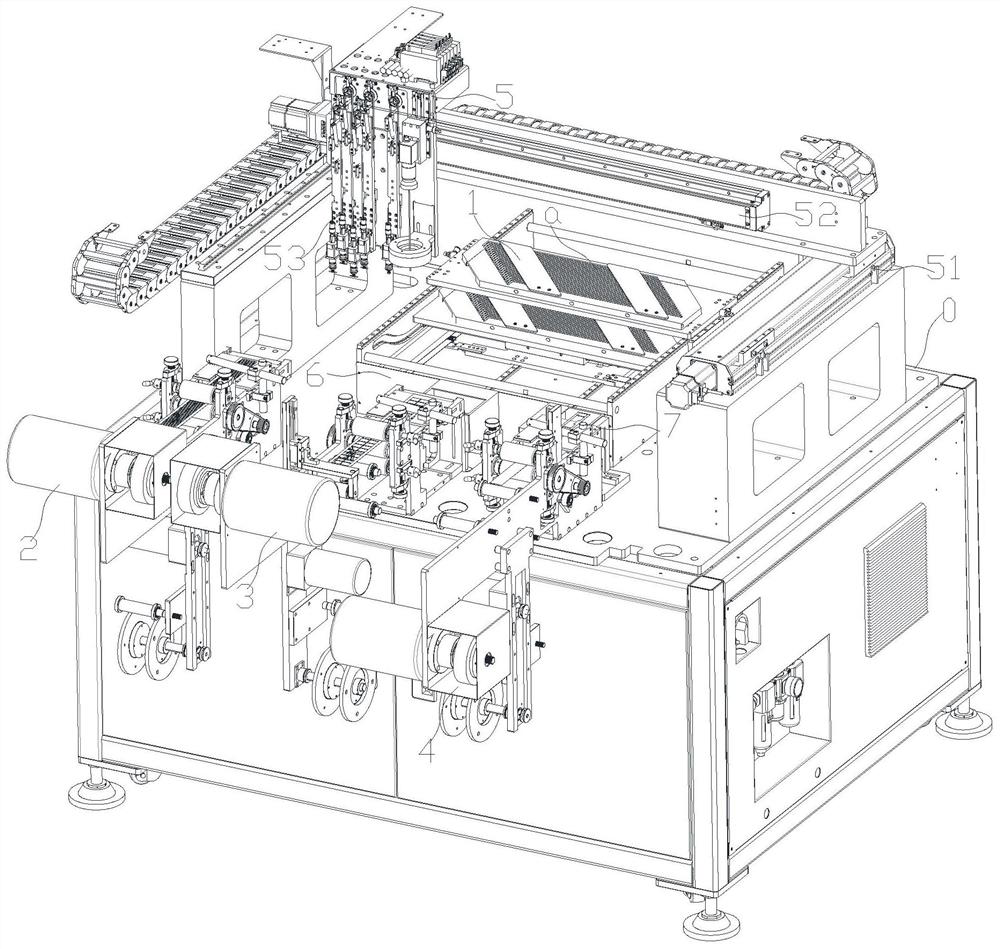

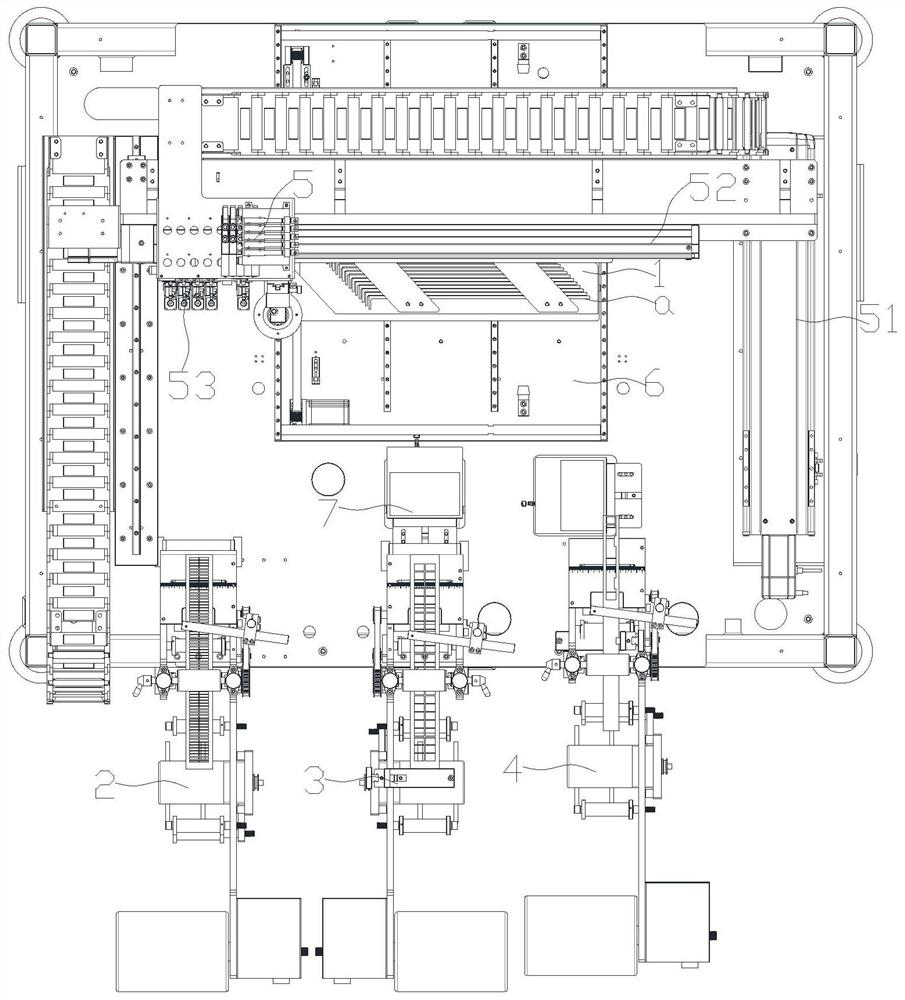

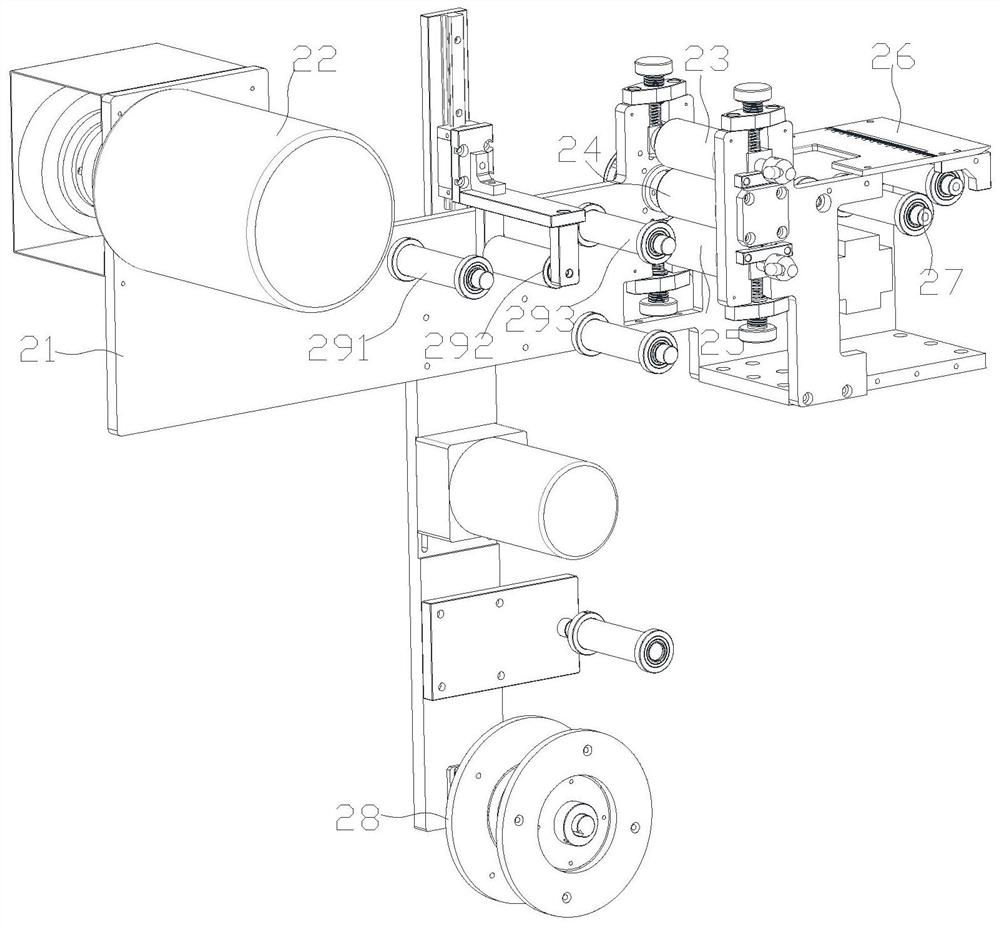

[0043] Figure 1-2 Schematically shows the film material transfer automation equipment for elongated workpieces according to an embodiment of the present invention, including machine 0, loading plate 1, first stripping device 2, second stripping device 3, the first Three stripping devices 4 and reposting devices 5; the loading plate 1, the first stripping device 2, the second stripping device 3, the third stripping device 4, and the posting device 5 are all arranged on the machine platform 0, and the first stripping device The material device 2, the second stripping device 3, and the third stripping device 4 are distributed in an array and are located on one side of the carrier plate 1, and the transfer device 5 is located at the first stripping device 2, the second stripping device 3, and the third stripping device. Above the feeding device 4, a number of w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com