Polyimide film for OLED flexible substrate and preparation method of polyimide film

A polyimide film and flexible substrate technology, applied in the field of optical materials, can solve the problems of limiting the application of OLED flexible substrates, high glass transition temperature, low linear expansion coefficient, etc., to achieve regular arrangement and close stacking, low Effect of thermal expansion coefficient and high heat resistance thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

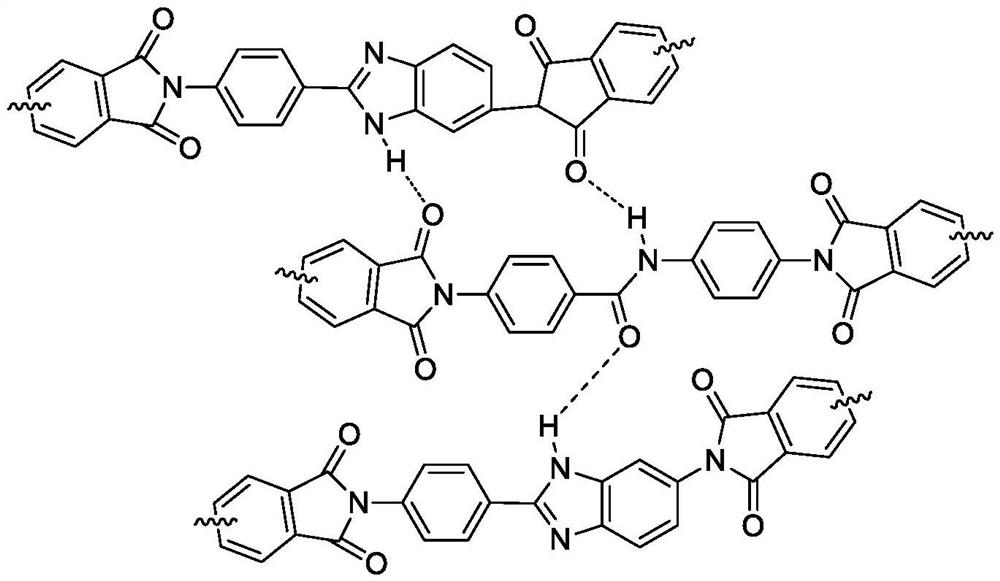

Method used

Image

Examples

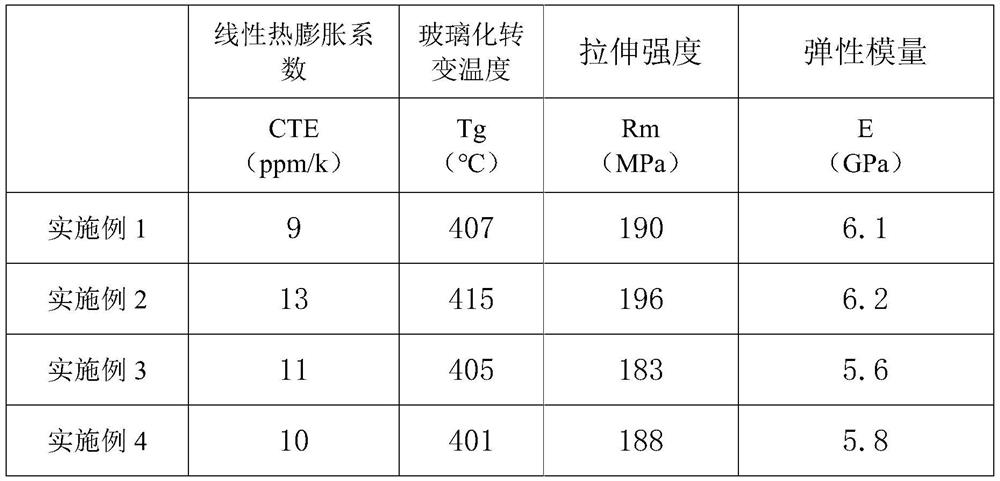

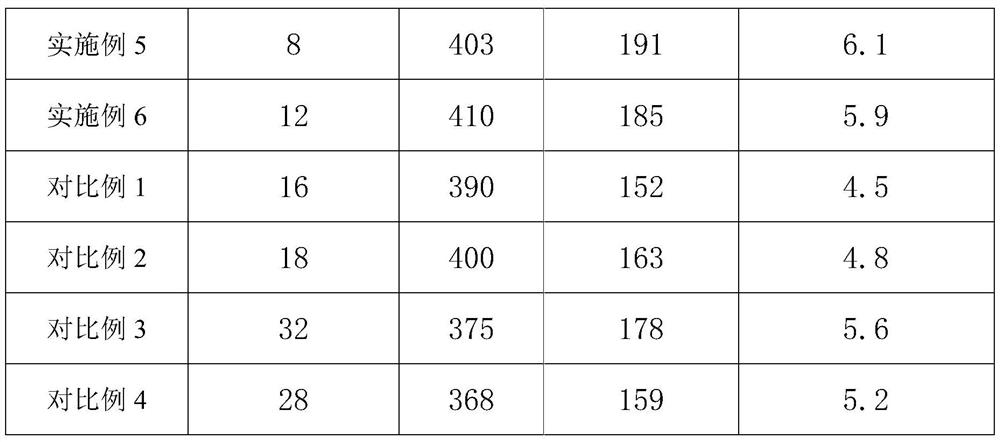

Embodiment 1

[0020] A kind of polyimide film for OLED flexible substrate, its preparation method comprises:

[0021] S1. Under nitrogen protection, pour 40mmol 3,3',4,4'-biphenyltetracarboxylic dianhydride into 30mmol 2-(3-aminophenyl)-5-aminobenzimidazole and 10mmol diaminobenzene In the N,N-dimethylacetamide solution of anilide, stirring and reacting at room temperature for 8 hours, a polyamic acid solution with a solid content of 10wt% was obtained;

[0022] S2. Coat the polyamic acid solution obtained above on a glass plate, place the glass plate in a drying oven, heat up to 80°C, dry for 1h, heat up to 200°C, dry for 2h, and wait until the temperature drops to 25°C Take out the glass plate, transfer the glass plate to a tube furnace, raise the temperature to 150°C, heat for 1h, then raise the temperature to 350°C, heat for 1.5h, then raise the temperature to 400°C, heat for 0.5h, cool down to 25°C and take it out. Place in water to remove the film, and then place the film in a drying...

Embodiment 2

[0025] A kind of polyimide film for OLED flexible substrate, the preparation method of this film is the same as embodiment 1, except that in step S1, 40mmol 4,4'-(hexafluoroisopropylene) diphthalic anhydride monomer is poured into the solvent There are 30mmol2-(3-aminophenyl)-5-aminobenzimidazole and 10mmol diaminobenzanilide in the N,N-dimethylacetamide solution, the relevant properties of the polyimide film thus obtained The test results are also shown in Table 1.

Embodiment 3

[0027] A polyimide film for OLED flexible substrates, the preparation method of the film is the same as in Example 1, except that in step S1, 40mmol 4,4'-oxydiphthalic anhydride monomer is poured into 30mmol 2-(3-aminophenyl)-5-aminobenzimidazole and 10mmol diaminobenzanilide in the N,N-dimethylacetamide solution, the relevant performance test of the polyimide film thus obtained The results are also shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com