Superhydrophilic/underwater superoleophobic copper mesh and its preparation method and application of separating emulsified oil-in-water

An underwater superoleophobic and emulsified water technology, which is applied in the fields of chemical engineering and superhydrophilic materials, can solve the problems of low flux and separation efficiency, and achieve the effects of high flux separation, excellent durability and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

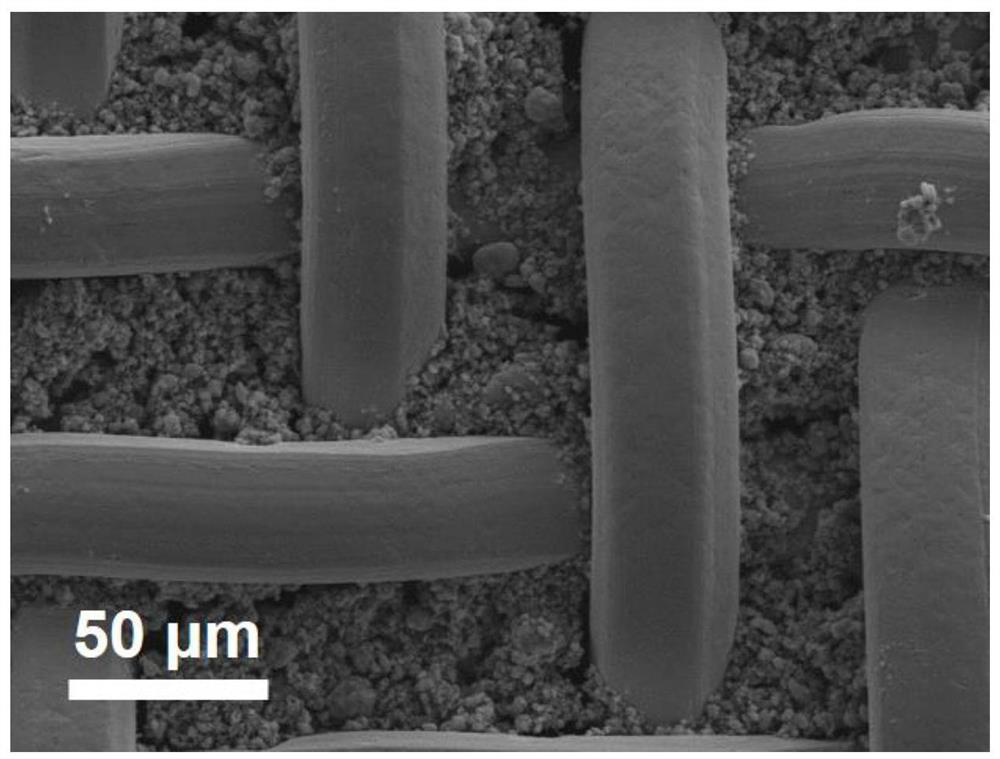

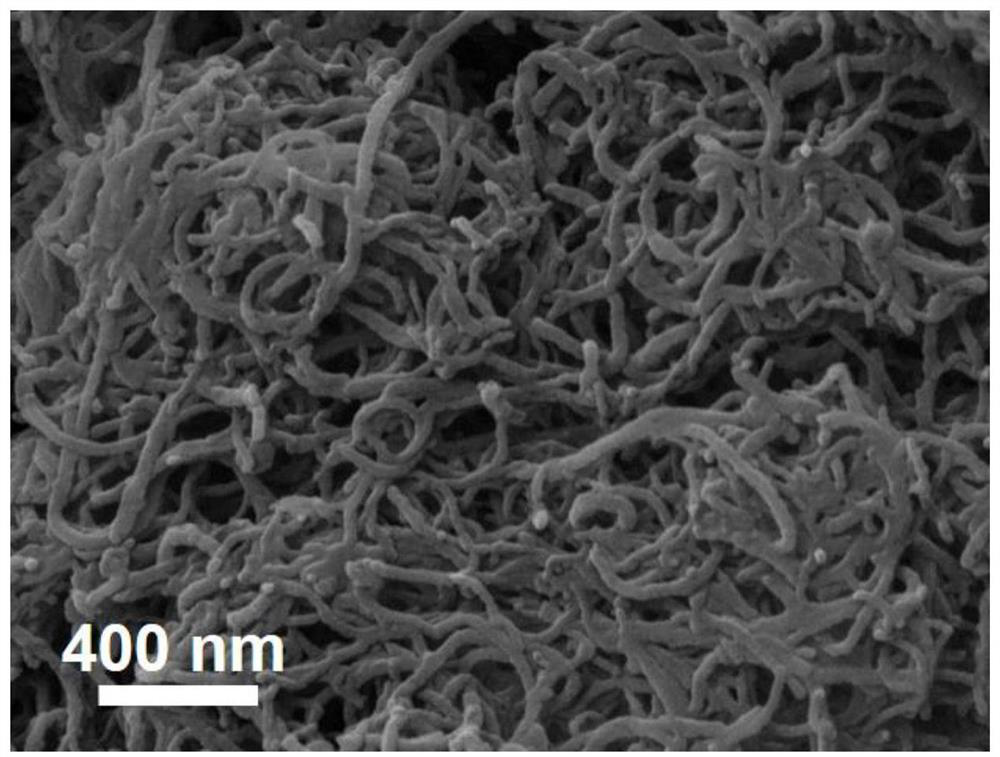

[0053] The 400-mesh phosphorus copper mesh (size 3cm×3cm) was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 minutes, and dried with nitrogen for use; ) solution, add 0.25g / L dopamine and 0.78g / L PEI, ultrasonically shake in a water bath for 5min, then add 0.2g / L MWCNTs-NH 2 , continue ultrasonication for 5 minutes to obtain the dipping solution; soak the cleaned copper grid in the above dipping solution, transfer the whole system to the shaker, set the rotation speed of the shaker to 120rpm, the dipping time is 6h, and the dipping temperature 25°C; after taking it out, dry it in an oven at a drying temperature of 100°C and a drying time of 10 minutes to obtain a superhydrophilic / underwater superoleophobic copper mesh.

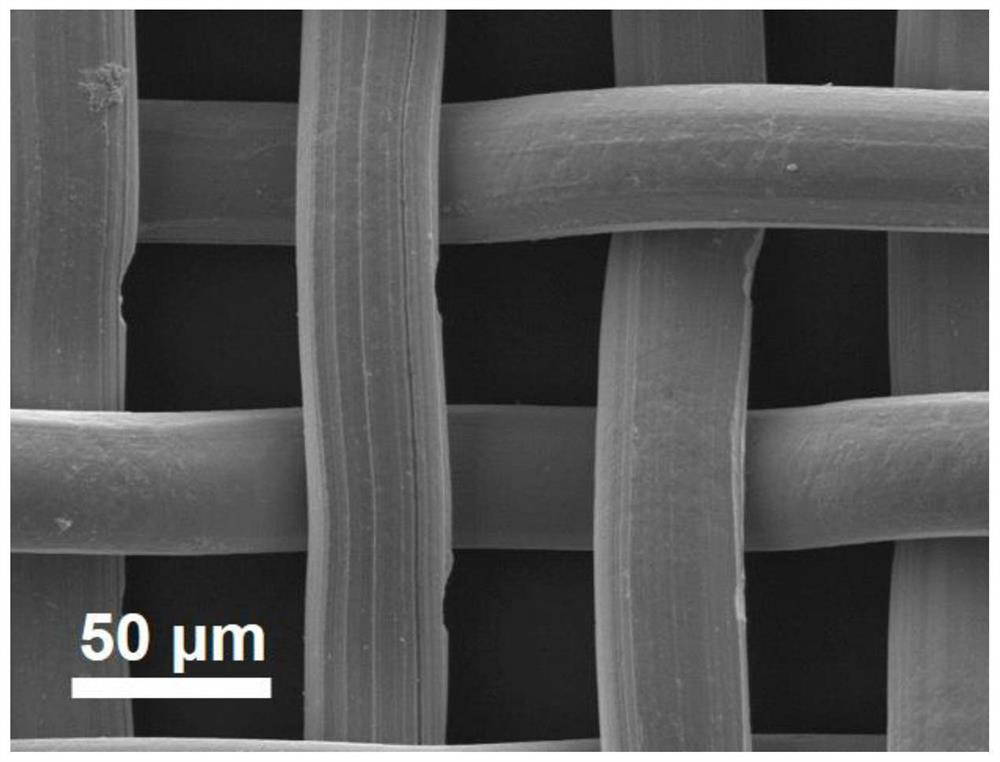

[0054] figure 1 It is a scanning electron microscope (SEM) picture of the 400-mesh phosphor copper mesh that has only been cleaned in the present invention. figure 1 It can be seen that the pore size of the unmodified copper...

Embodiment 2

[0060] The 400-mesh phosphorus copper mesh (size 3cm×3cm) was ultrasonically cleaned with acetone, absolute ethanol and deionized water for 10 minutes, and dried with nitrogen for use; ) solution, add 0.25g / L of dopamine and 0.78g / L of PEI, ultrasonically shake in a water bath for 5min, and then add 0.25g / L of MWCNTs-NH 2 , and continue ultrasonication for 5 minutes to obtain the dip coating solution; soak the cleaned copper grid in the above dip coating solution, transfer the whole system to the shaking table, set the rotation speed of the shaking table to 120rpm, dip the coating time to 8h, dip coating temperature 25°C; after taking it out, dry it in an oven at a drying temperature of 100°C and a drying time of 10 minutes to obtain a superhydrophilic / underwater superoleophobic copper mesh.

Embodiment 3

[0062] A 400-mesh phosphorus copper mesh (size 3cm×3cm) was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 min, and dried with nitrogen for use; ) solution, add 0.30g / L dopamine and 0.85g / L PEI, ultrasonically shake in a water bath for 5min, then add 0.25g / L MWCNTs-NH 2 , continue ultrasonication for 5 minutes to obtain the dip coating solution; soak the cleaned copper grid in the above dip coating solution, transfer the whole system to the shaking table, set the rotation speed of the shaking table to 130rpm, dip the coating time to 10h, dip coating temperature 30°C; take it out and dry it in an oven at a drying temperature of 120°C and a drying time of 30 minutes to obtain a superhydrophilic / underwater superoleophobic copper mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com