Lateral moving device of hanging basket formwork

A technology of formwork and built-in poles, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as unsatisfactory safety, hidden safety hazards, beam damage, etc., and achieve saving and transportation, efficient overall construction, and overall construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

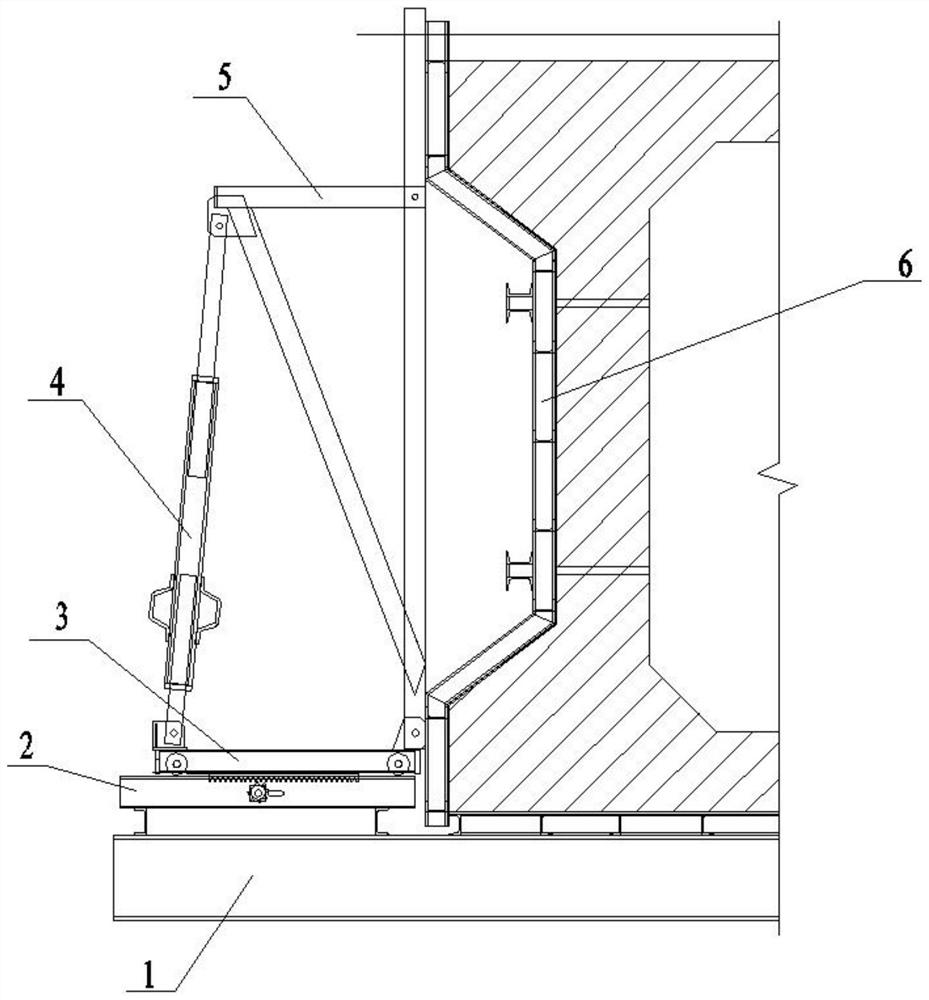

[0021] see figure 1 , the hanging basket formwork side shifting device provided by the present invention includes a lateral working platform 2, a mobile trolley 3, a lateral adjustment rod 4 and a triangle stabilizer 5; the mobile trolley 3 is placed on the upper surface of the lateral working platform 2 and works sideways The upper surface of the platform 2 slides freely; one end of the lateral adjustment rod 4 is movably arranged on the mobile trolley 3, and the other end is movably connected with a vertex of the triangular stabilizer 5;

[0022] Between the lateral adjustment rod 4 and the mobile dolly 3, between the lateral adjustment rod 4 and the triangular stabilizer 5, and between the triangular stabilizer 5 and the mobile dolly 3 are all connected by pin shafts.

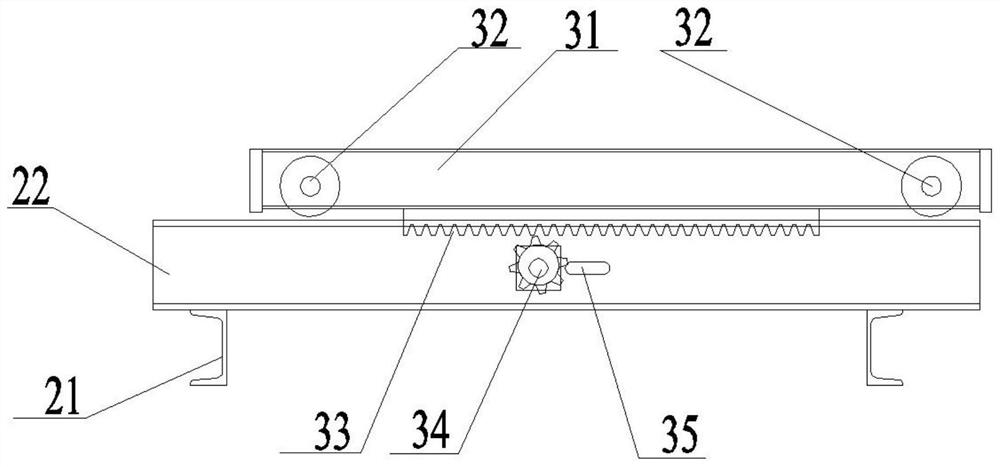

[0023] see figure 2 The mobile trolley 3 used in the present invention includes a car body 31 and steel rollers 32 placed on the side of the car body; the steel rollers 32 are placed on the upper surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com