A treatment method for shield shell grouting wrapping of shield machine

A treatment method and wrapping technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, earth-moving drilling and mining, etc., can solve the unfavorable shield construction risks, construction period and cost control, uncontrollable shield tunneling attitude, shield The driving force of the mechanism is large, so as to achieve the effect of controllable driving attitude, avoiding water and sand gushing, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

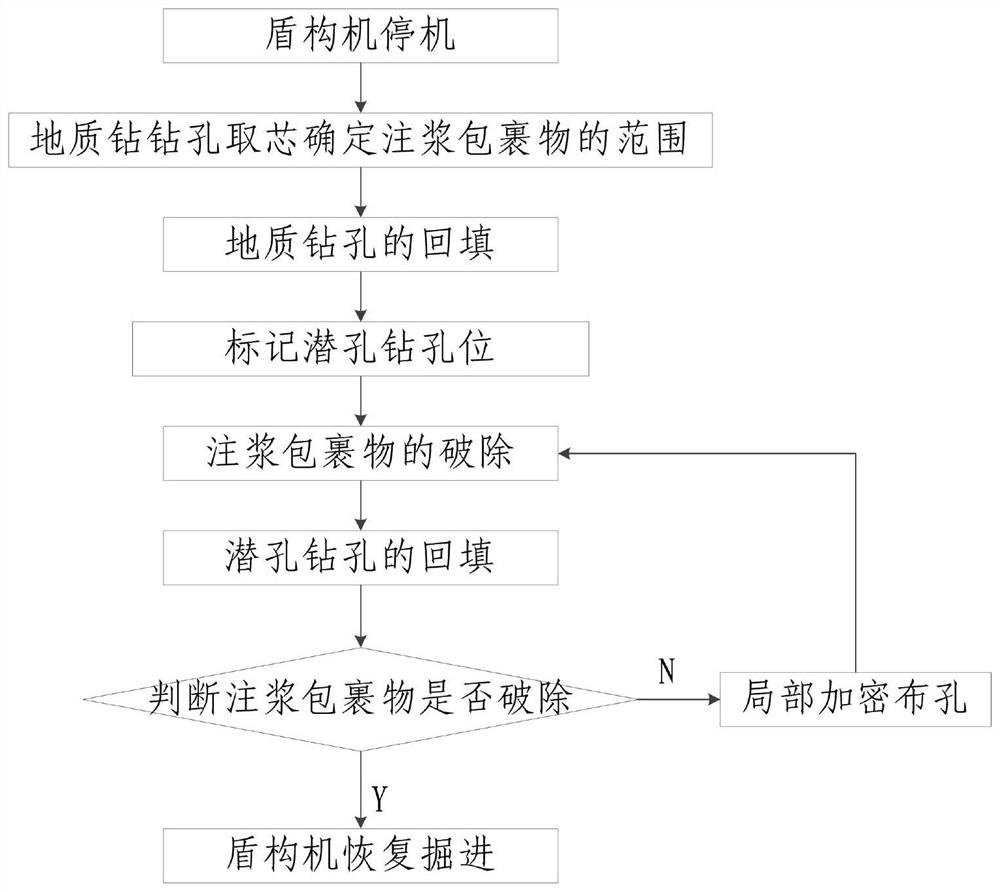

[0043] Such as Figure 1 to Figure 6 A treatment method for the grouting wrapping of a shield shell of a shield machine shown includes the following steps:

[0044] Step 1. Stop the shield machine;

[0045] In actual use, when the upper surface of the shield machine is wrapped by the mortar produced by synchronous grouting, the tunneling attitude of the shield machine will be uncontrollable and the thrust of the shield machine will be large. Due to the excessive thrust, the design thrust of the shield machine cannot be reached. Satisfy the propulsion requirement for the shield machine to move forward, causing the shield machine to stop.

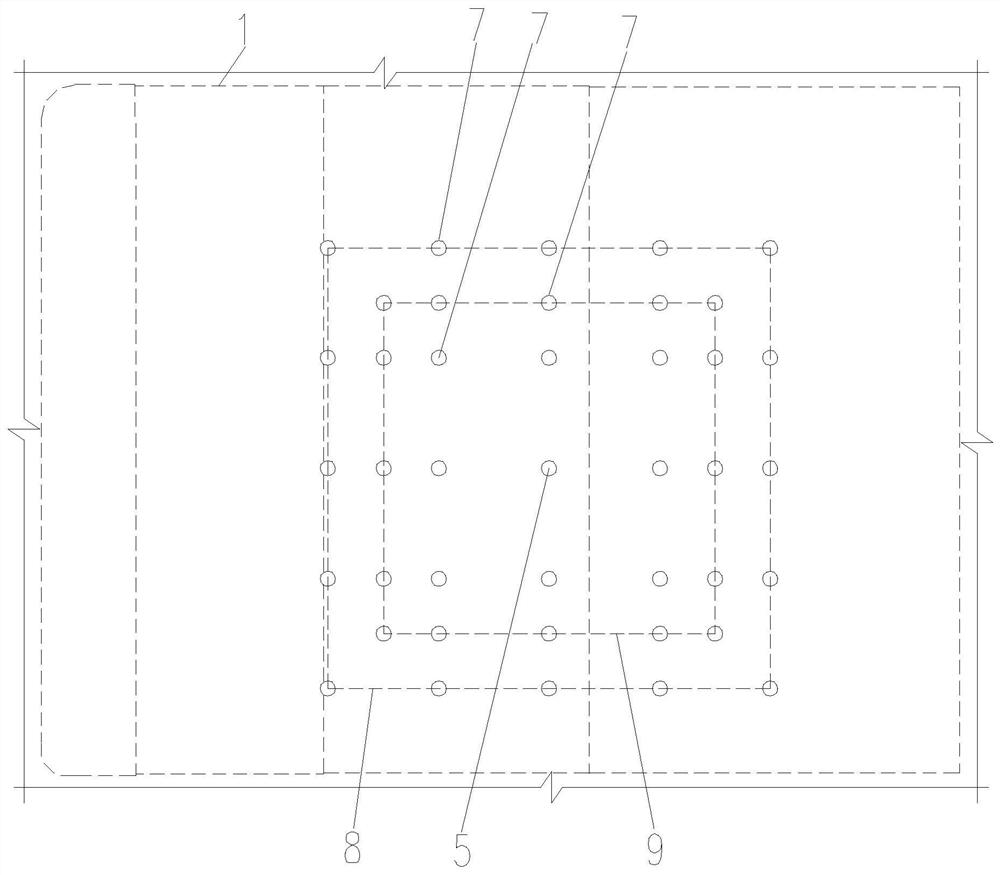

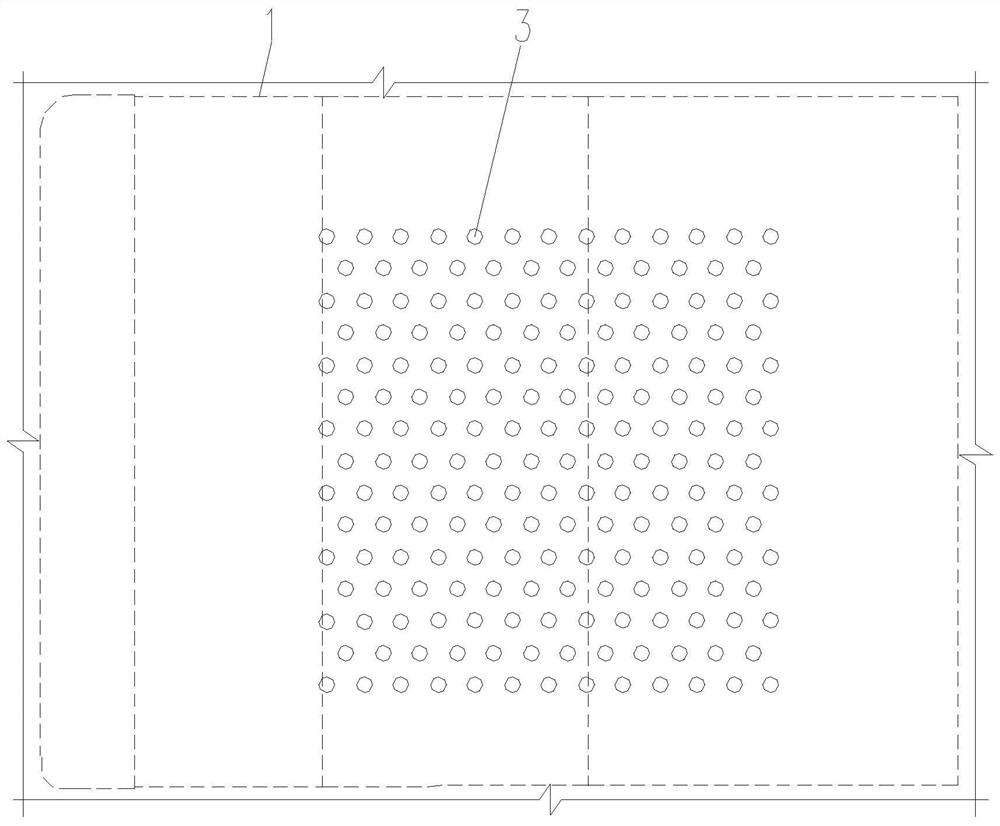

[0046]Step 2. Geological drilling and coring to determine the scope of grouting inclusions: on the ground above the shield machine, use a total station to locate the position of the shield machine on the ground, and locate the position of the shield machine on the ground Mark multiple circles of geological drilling positions at the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com