Flexible supporting structure

A technology of supporting structure and supporting cylinder, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of difficult disassembly of separate cylinders and flexible supports, disturbance of high-temperature gas flow, and large local stress due to heating, etc., to avoid problems such as Air leakage risk, thermal stress reduction, good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

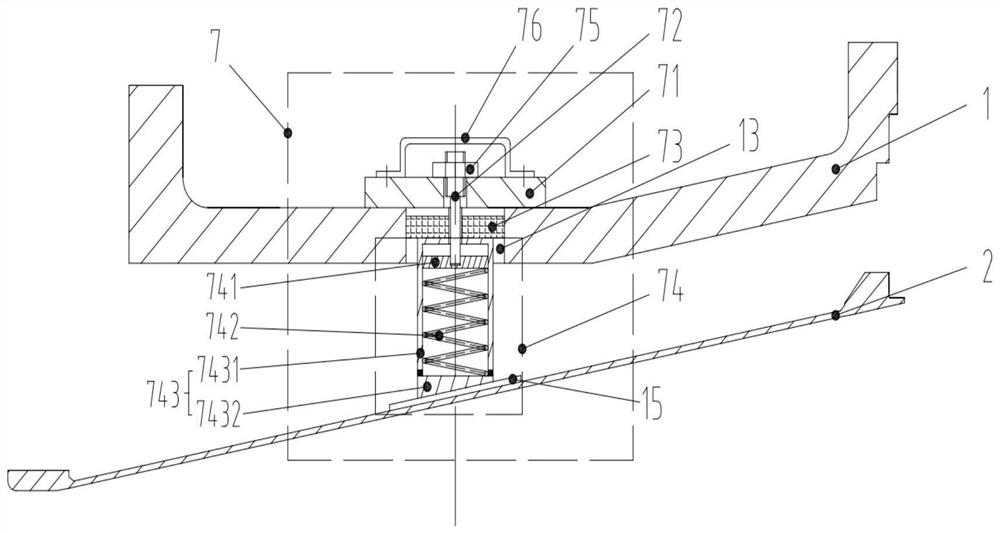

[0038] figure 2 As shown, a flexible support structure 7 is used to support and connect the gas turbine exhaust cylinder inner flow passage 12 and the outer cylinder block 1, including a mounting plate 71, an adjusting bolt 72, a gasket 73 and an adjustable support tube 74, and the mounting plate 71 Installed on the outer cylinder body 1 through threaded connection, the adjustable support tube 74 is installed on the outer plate 2 of the inner flow channel 12 by welding, the sealing gasket 73 is arranged between the mounting plate 71 and the adjustable support tube 74, and the adjusting bolt 72 passes through the mounting plate 71 and the gasket 73 and is connected with the adjustable support tube 74;

[0039] The adjustable support tube 74 includes a shell 743, a spring 742 and a connecting plate 741. The shell 743 includes an upper shell 7431 and a lower shell 7432. The upper shell 7431 and the lower shell 7432 are welded and fixed to form a hollow cavity structure. The spri...

Embodiment 2

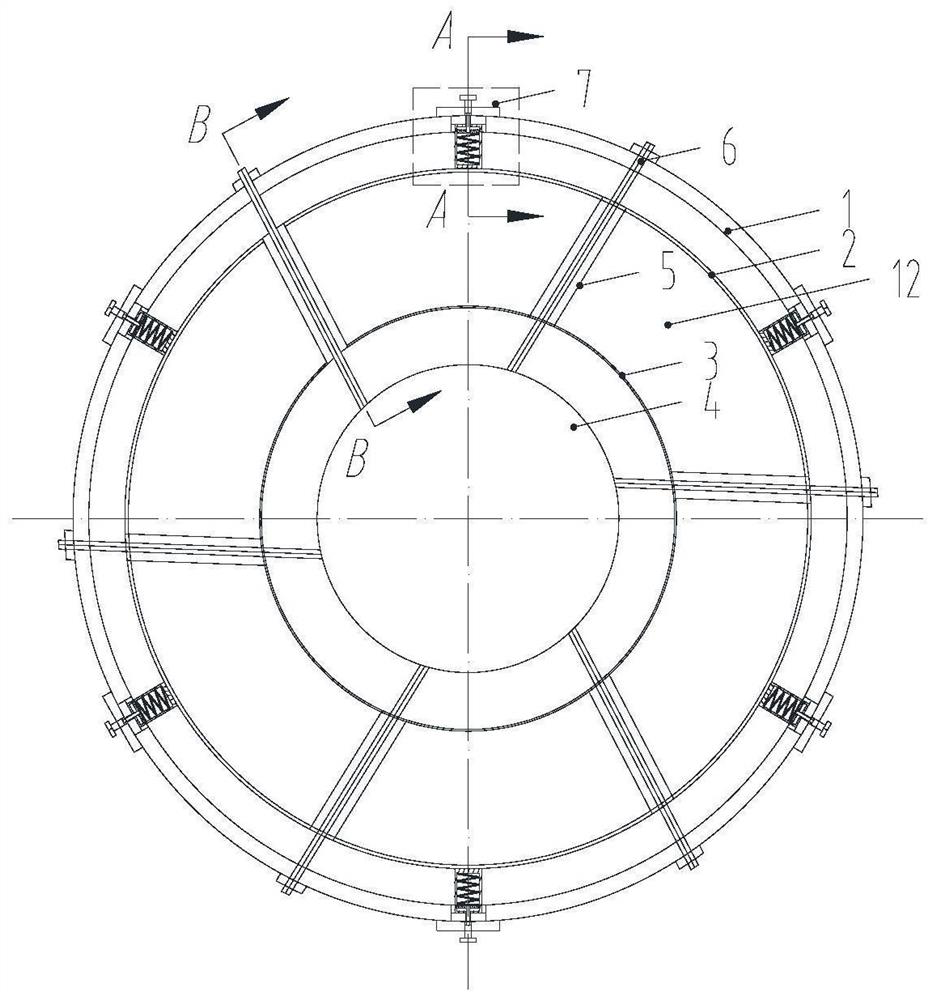

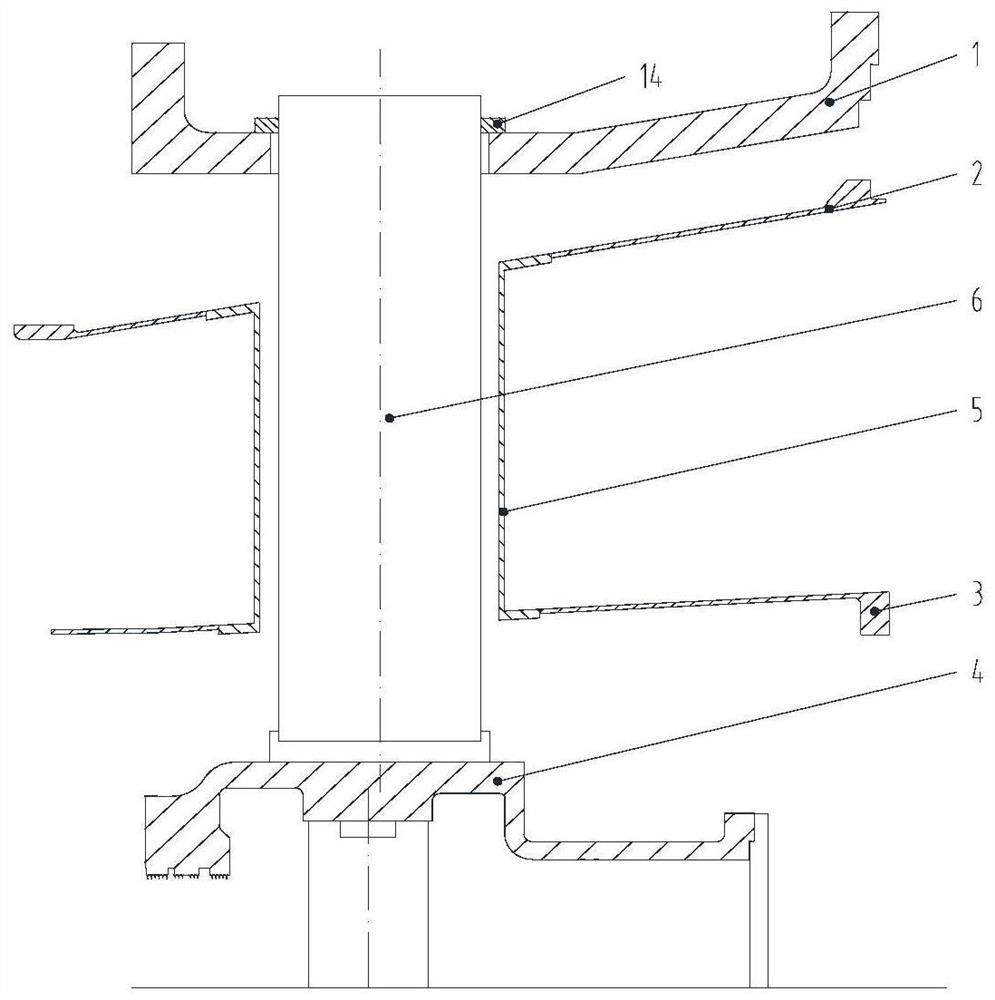

[0044] figure 1 and image 3As shown, an exhaust cylinder is used for a gas turbine, including an outer cylinder body 1 and an inner flow channel 12, the inner flow channel 12 includes an outer plate 2, an inner plate 3 and a support cylinder 5, and the outer cylinder body 1 and the inner flow channel 12 The outer panels 2 are connected by a flexible support structure 7 .

[0045] It also includes a support rod 6 and a support seat 4 , one end of the support rod 6 is welded and fixed to the support seat 4 , and the other end passes through the snap ring 14 and is fixedly connected to the outer cylinder body 1 .

[0046] The bottom of the shell 743 of the adjustable support tube 74 is set as a slope, the slope slope is the same as the slope of the outer plate 2, and the extension line of the center line of the flexible support structure 7 coincides with the center of gravity of the inner runner 12 in the exhaust cylinder 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com