Seam width-adjustable circular seam type spray disc and atomization device

A technology for adjusting seams and annular seams, applied in the field of powder metallurgy, can solve the problems of poor control of precision and strength, affecting the stability of atomization, powder quality, and difficulty in processing and cleaning, so as to avoid air leakage. Risk, cost and manpower savings, effect of improving air pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

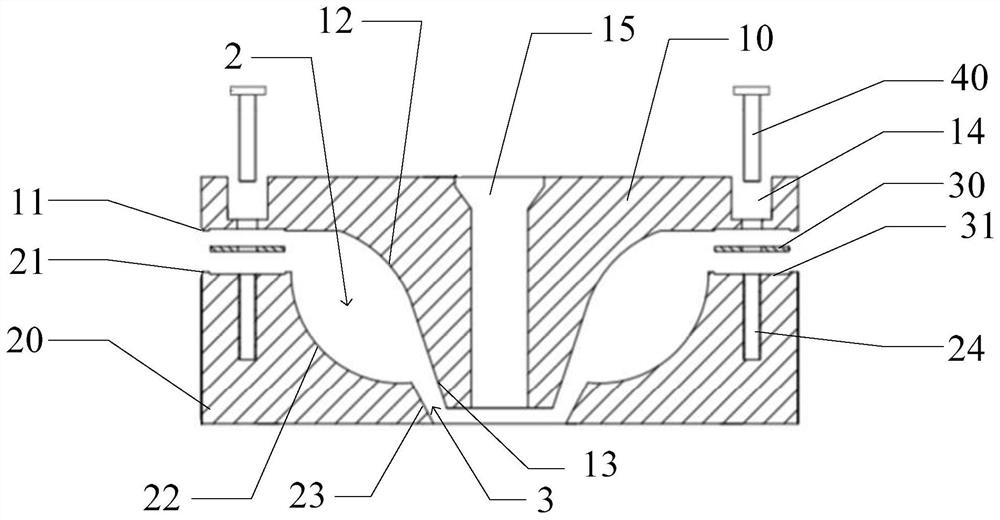

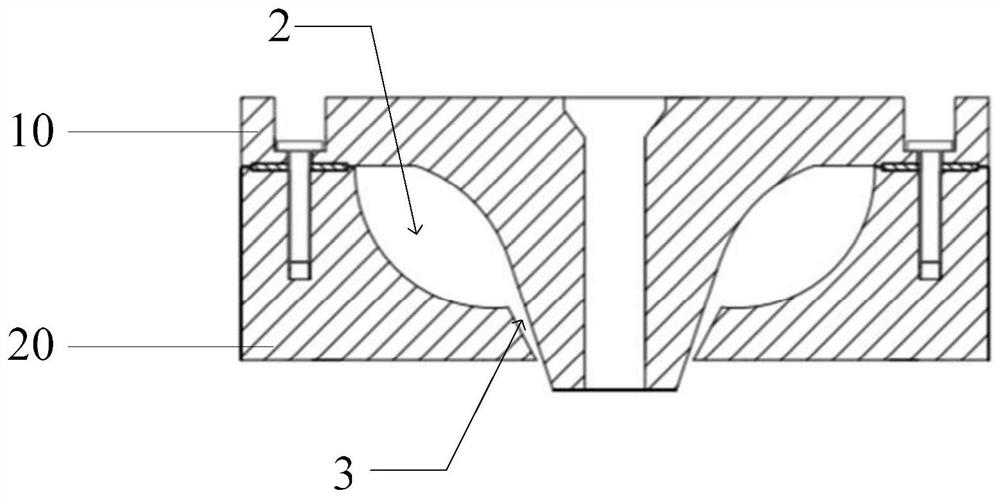

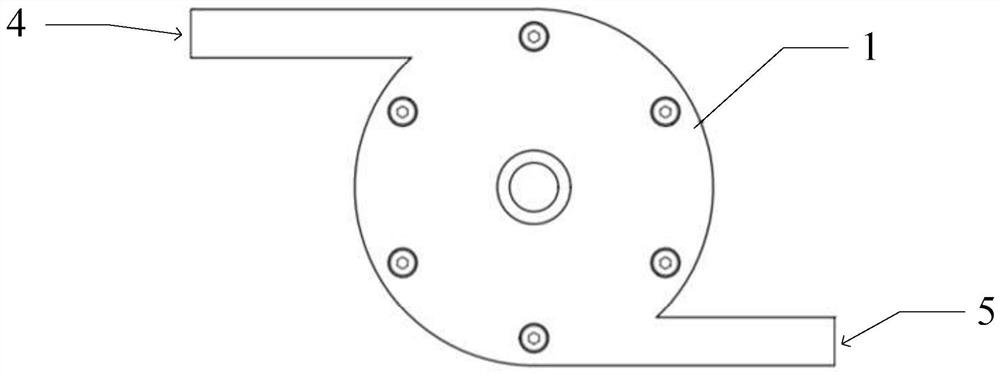

[0032] Such as Figure 1-4 As shown, the present invention provides a circular seam type spray plate 1 that can adjust the width of the slit, including: an upper plate body 10, a lower plate body 20, and a plurality of gaskets 30, and the upper plate body 10 has a The first flange 11, the first half channel 12 arranged on the lower side, the first half annular seam 13 connected with the first half channel 12; the lower plate body 20 has a second flange 21 arranged on the edge , the second half-runner 22 arranged on the upper side, the second half-annular seam 23 connected with the second half-runner, the upper disc body 10 and the lower disc body 20 pass through the first flange 11. The second flange 21 is connected, and the first half-flow channel 12 and the second half-flow channel 22 form a complete flow channel 2 and the intake air after the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com