A wind power blade root embedded bolt positioning device and method

A technology for pre-embedding bolts and wind turbine blades, which is applied to household appliances, other household appliances, household components, etc., can solve the problem of not easy to ensure the flatness of the end face of the blade root, and the sealing problem of auxiliary tooling and blade root mold. It is not easy to ensure the flatness of the blade root end face, etc., to prevent the penetration of the cured resin into the bolt sleeve, ensure the flatness, and ensure the quality of the blade root.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

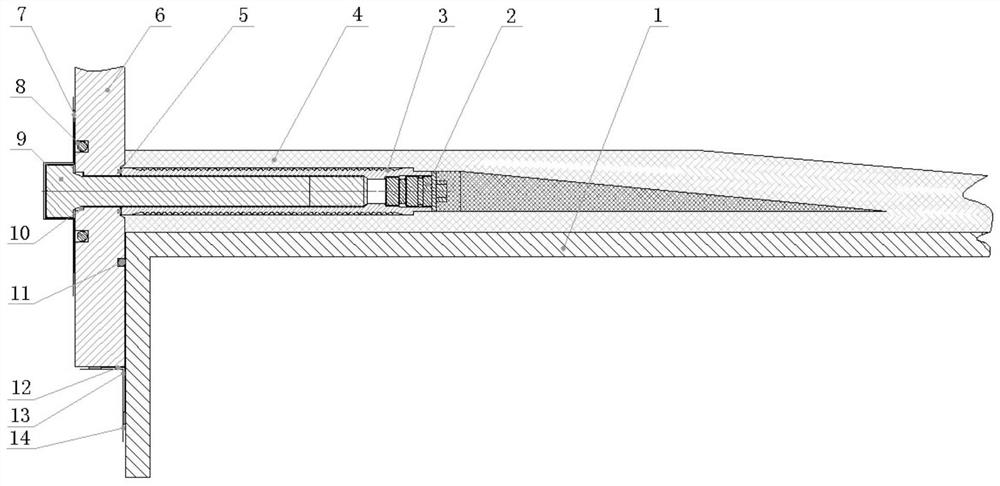

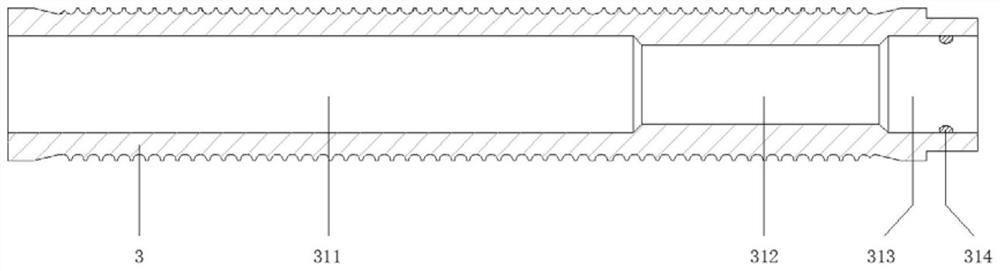

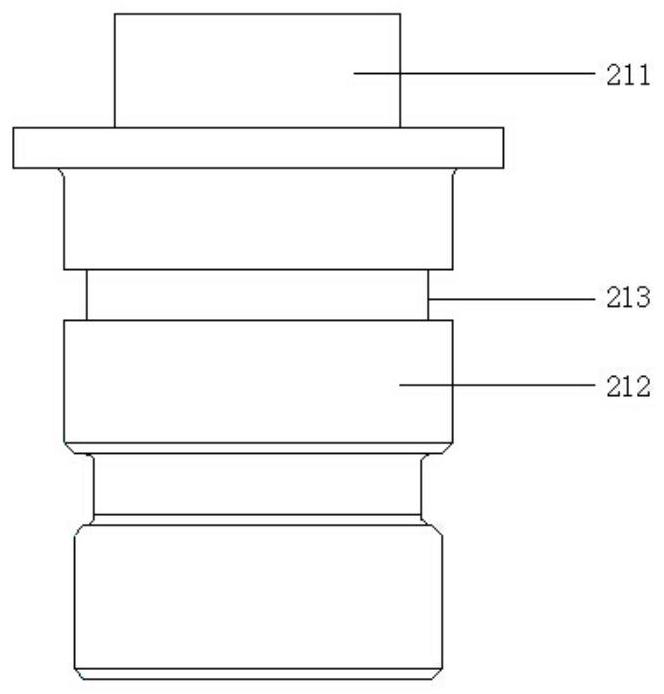

[0051] as attached Figure 1-11 As shown, the present invention includes a blade root reinforcement layer 4 laid on the mold 1, one end is inserted into the blade root reinforcement layer 4, the other end is inserted into the flange plate 6, and the bolt sleeve 3 is inserted into the flange plate 6, and the The plate 6 is inserted into the positioning bolt 9 in the bolt sleeve 3, and the flange plate 6 is provided with a slot 613 matched with the bolt sleeve 3, and the flange plate 6 is provided with a through hole for the positioning bolt 9 to pass through. hole 612, a positioning bushing 10 for correcting the axis of the positioning bolt 9 is provided between the positioning bolt 9 and the flange plate 6, and a positioning groove 611 for embedding the positioning bushing 10 is provided on the flange plate 6 One end of the bolt sleeve 3 plugged into the blade root reinforcement layer 4 is provided with a sealing insert 2 for sealing the bolt sleeve 3, a sealing element I is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com