Linear type movable pipe peristaltic pump

A peristaltic pump, linear technology, applied in the field of linear moving tube peristaltic pump, can solve the problems of accuracy error, hose deformation, pipeline deformation and wear, etc., to improve accuracy stability, increase service life, and reduce friction loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

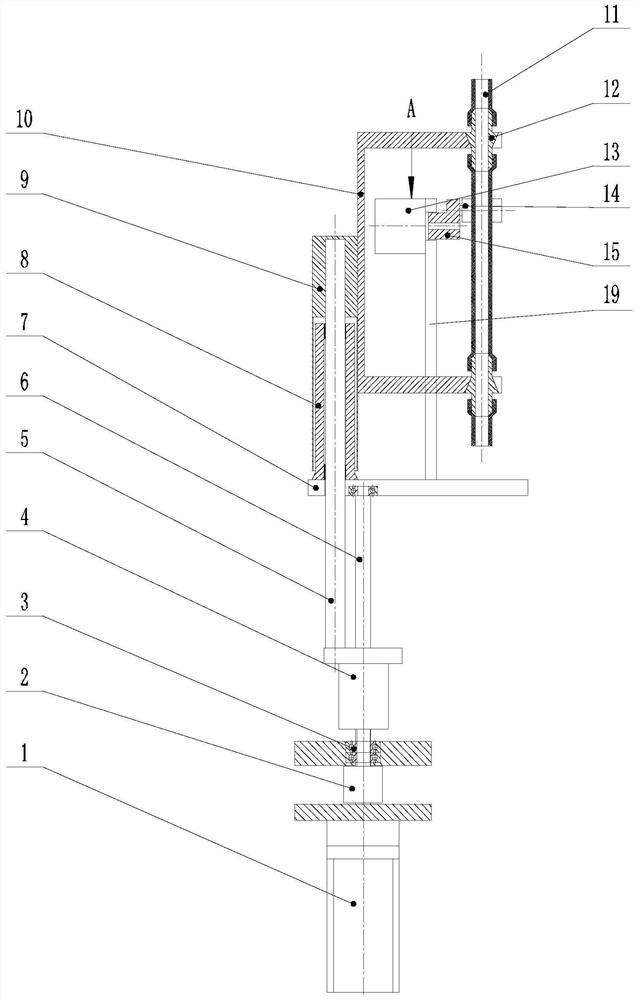

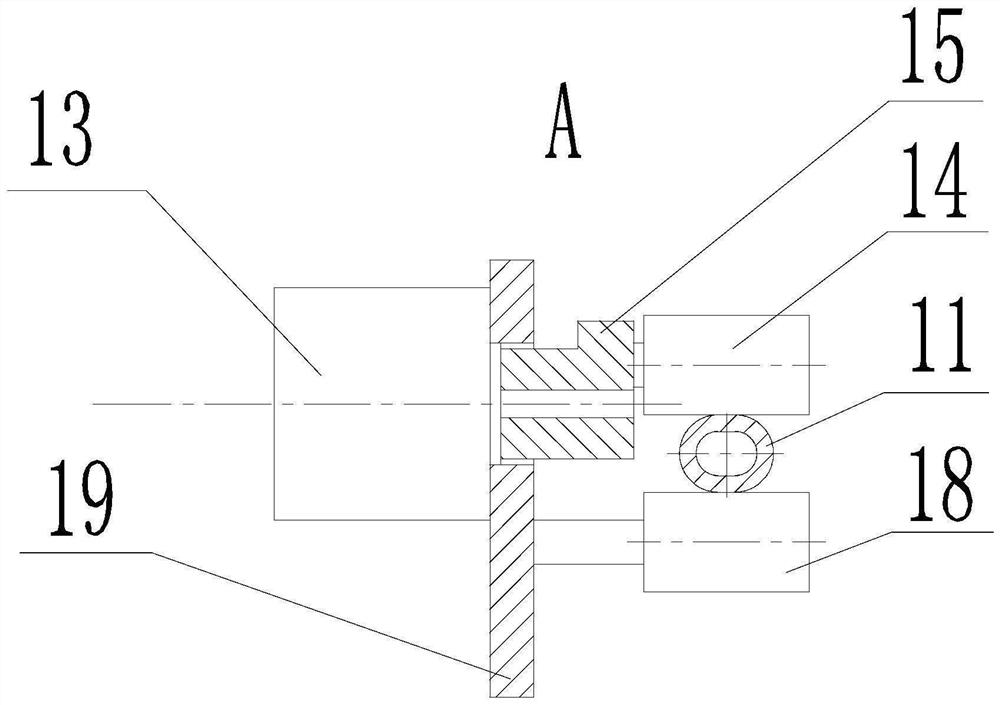

[0029] Such as figure 1 and figure 2 As shown, a linear moving tube peristaltic pump of the present invention includes: a pump body assembly, a pipeline assembly, a shut-off assembly, a pressure tube assembly and at least one set of linear reciprocating components; the shut-off assembly is used to clamp and loosen the tube The linear reciprocating motion assembly and the pressure tube assembly are installed on the pump body assembly; the pipeline assembly is connected with the linear reciprocating motion assembly, and the pipeline assembly follows the reciprocating motion of the linear reciprocating motion assembly; the pressure tube assembly Squeeze the reciprocating pipeline components to complete the pumping and metering of materials.

[0030] In this embodiment, both the linear reciprocating assembly and the pressure tube assembly are installed on the pump body assembly; the pipeline assembly is connected to the linear reciprocating assembly, and the pipeline assembly re...

Embodiment 2

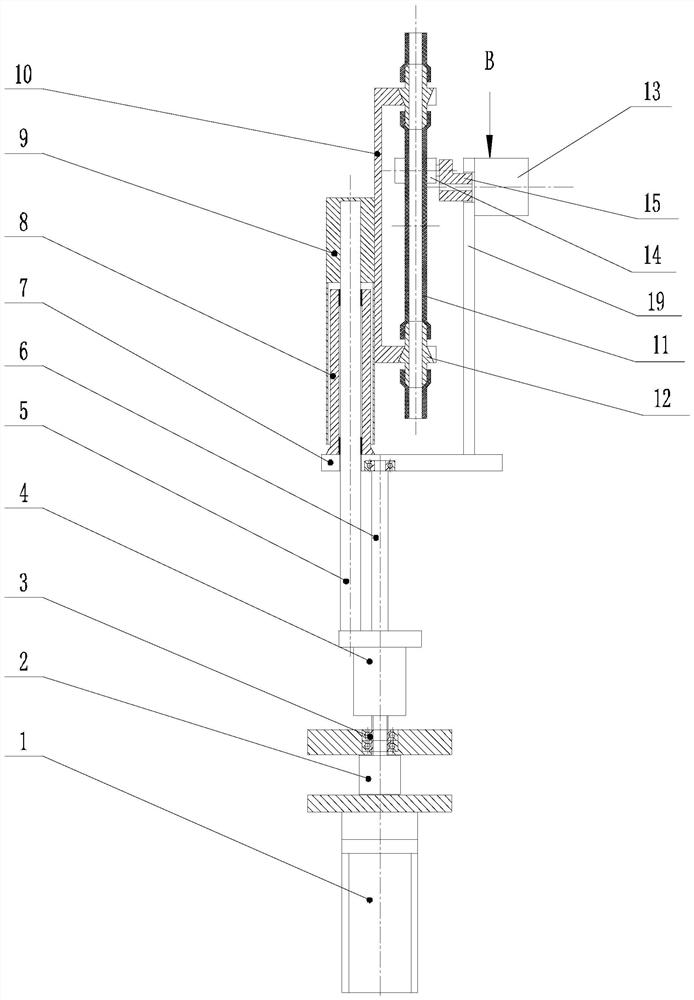

[0042] Such as image 3 and Figure 4 As shown, the structure and working principle of the linear moving tube peristaltic pump of the present invention are roughly the same as those of the linear moving tube peristaltic pump in Embodiment 1, the difference is that the pressure tube assembly is arranged on the bracket 10 through the mounting plate 19 The outer side, that is, the bracket 10 and the pressure tube assembly are located on different sides of the elastic hose 11 . In this embodiment, by arranging the bracket 10 and the pressure tube assembly on different sides of the elastic hose 11, the installation volume of the bracket 10 is reduced, and the lateral distance between the bracket 10 and the elastic hose 11 is also shortened, which is beneficial Improving the transmission stability between the bracket 10 and the elastic hose 11 is also beneficial to reducing the overall installation volume of the peristaltic pump.

Embodiment 3

[0044] Such as Figure 5 As shown, a linear moving tube peristaltic pump of the present invention has substantially the same structure and working principle as the linear moving tube peristaltic pump in Embodiment 1, the difference is that the pump body assembly includes a pump body baffle 20; The linear reciprocating motion assembly includes a first driving power part 1 and a lead screw 6; one end of the lead screw 6 is connected to the output end of the first driving power part 1 through a coupling 2, and the other end of the lead screw 6 is connected to the pump body baffle 20 connect. The lead screw 6 is provided with a lead screw nut 4 , and with the rotation of the lead screw 6 , the lead screw nut 4 reciprocates on the lead screw 6 ; the lead screw nut 4 is provided with a pipe joint clamping plate 16 .

[0045] Further, a bearing is provided at the joint between the lead screw 6 and the pump body baffle 20 , and the transmission stability of the lead screw 6 is improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com