Draw-bar box horizontal noise testing method

A technology of noise testing and trolley case, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., it can solve the problems of not considering the noise, the limitation of the test range, and the improvement, so as to improve flexibility, accuracy, The effect of overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

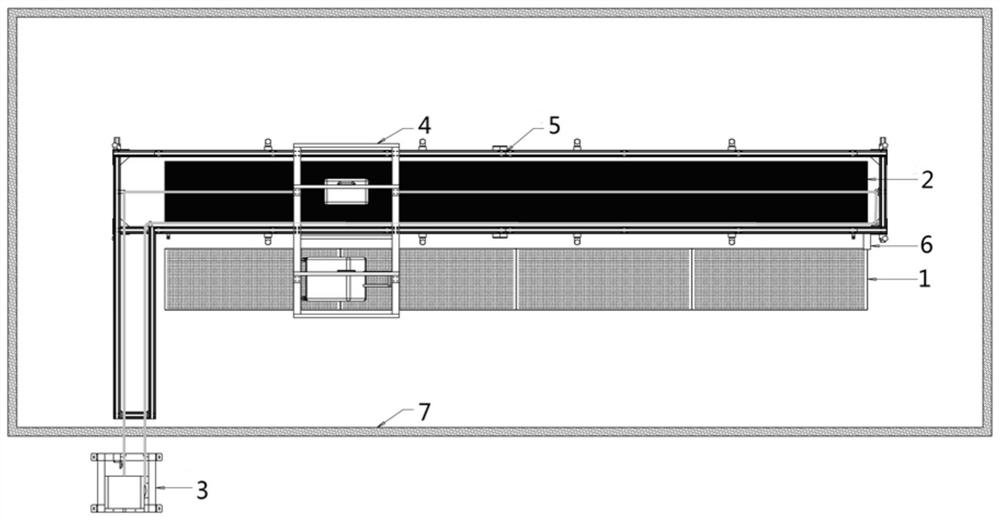

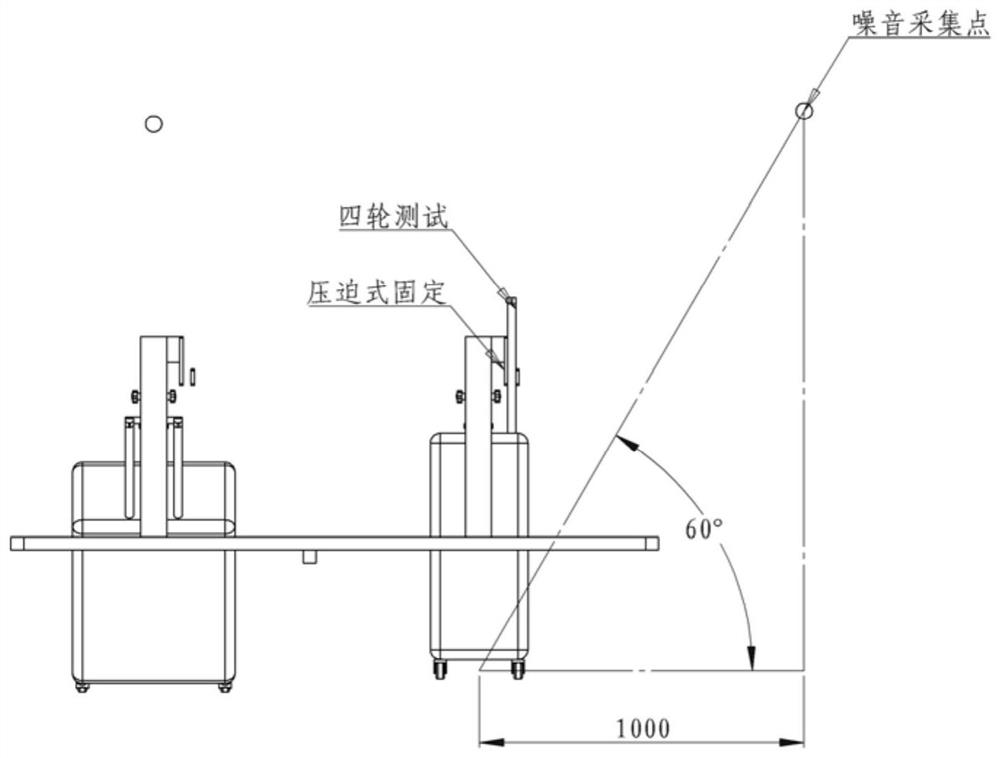

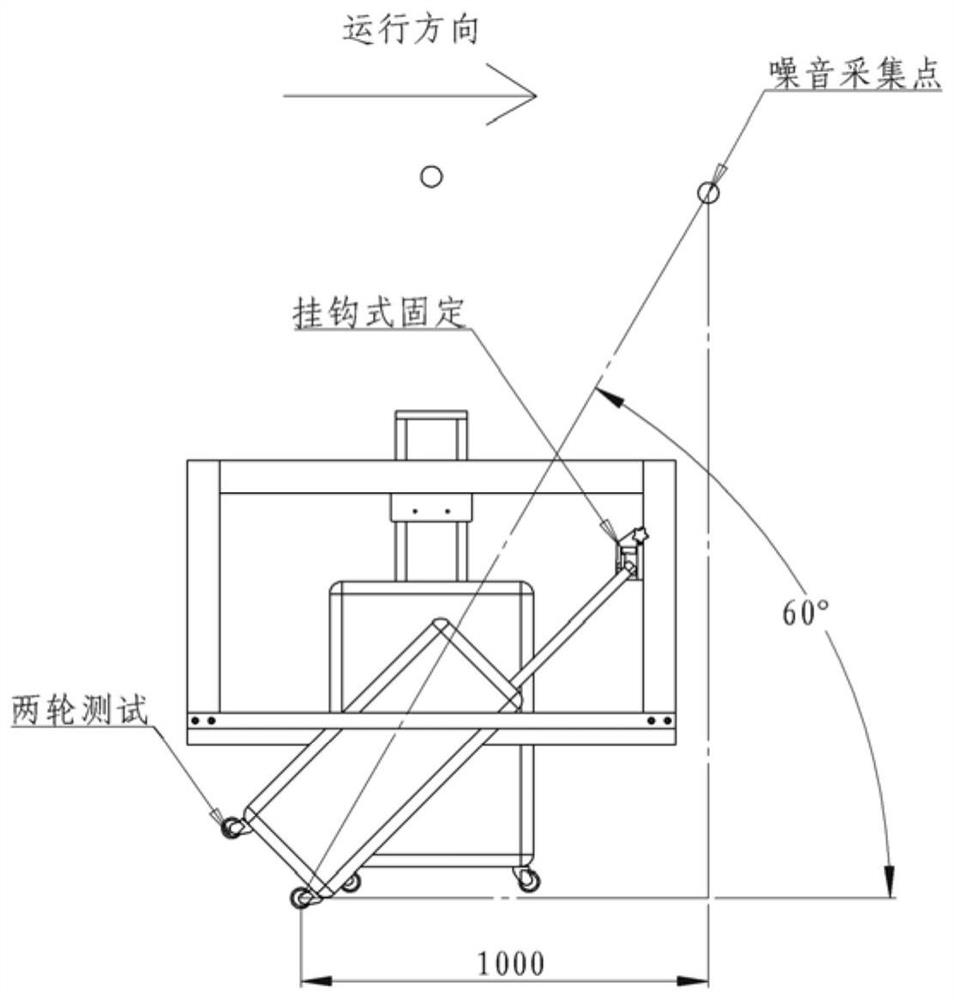

[0049] The present invention intends to implement a method for testing the horizontal noise of the trolley case. The purpose of the implemented technical means is to solve the problems caused by the use of the previous trolley case noise test method in terms of testing means, testing range, and testing accuracy. Big limitations, and it is impossible to form a targeted noise test system for the inherent field of trolley case products.

[0050] The technical solution implemented in the present invention mainly achieves the ultimate goal by designing a set of noise testing methods for the trolley case. Since the type of the trolley case used or the shapes of the traction components and fixing components used are different, the involved The range is relatively wide, and for conventional technical means that are not within the scope of the technical solution of the present invention, for example, this embodiment does not need to refine the possible shape structure of the trolley cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com