Soft package battery cell module of spot welding process

A cell module and process technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of replacement of cells, shorten the service life of cells, and poor use effect, and achieve extended service life, The effect of increasing clearance space and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

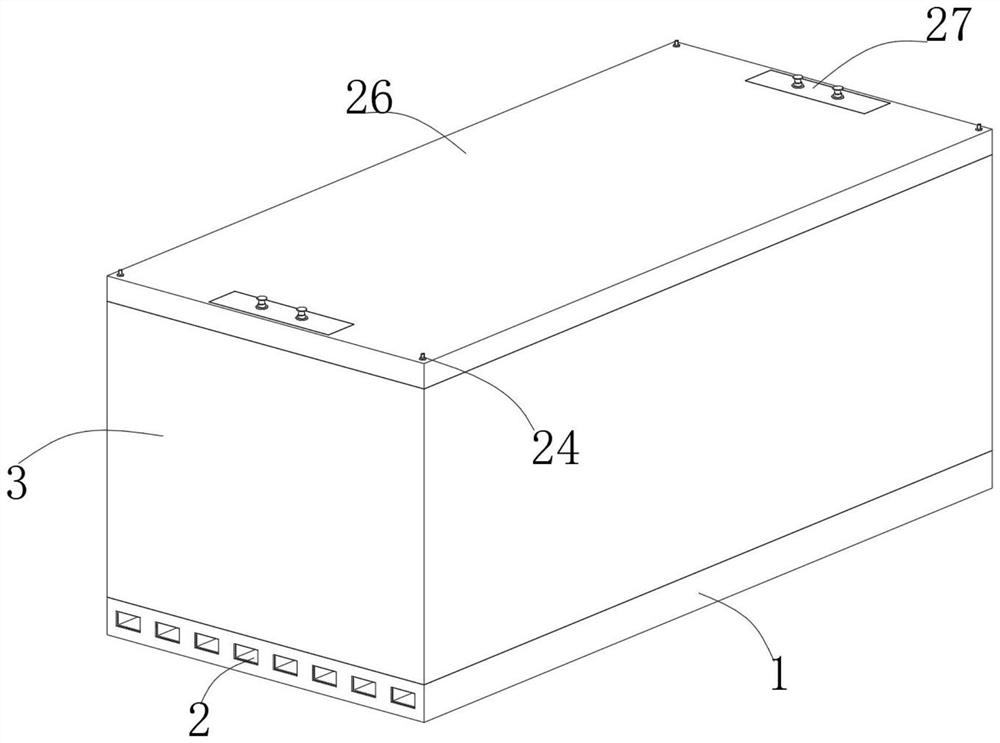

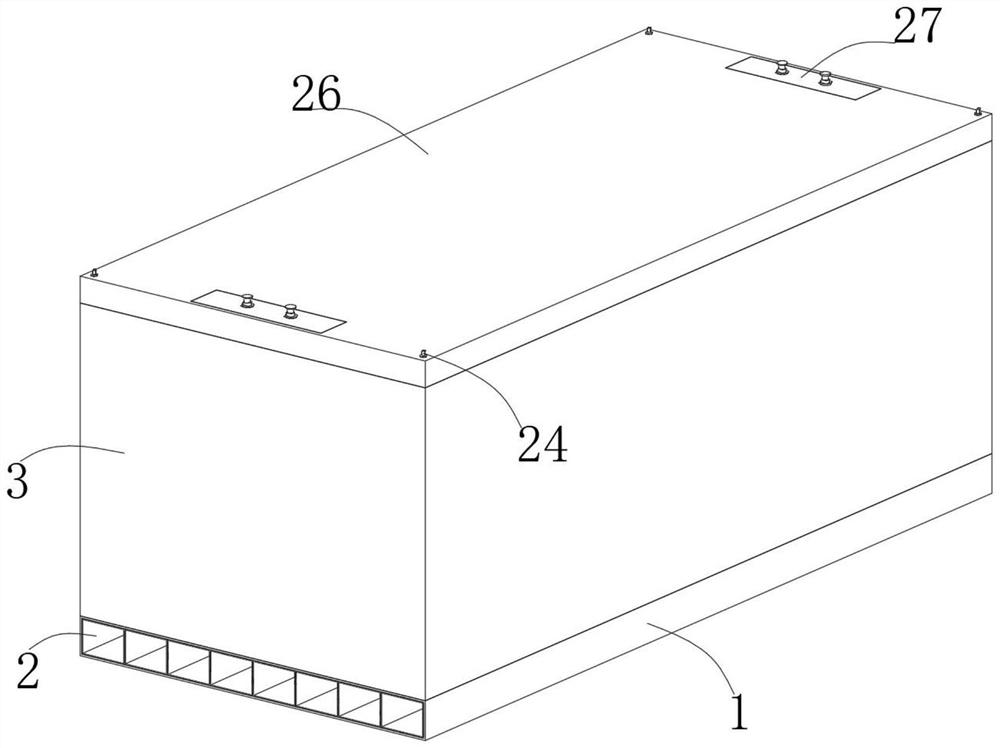

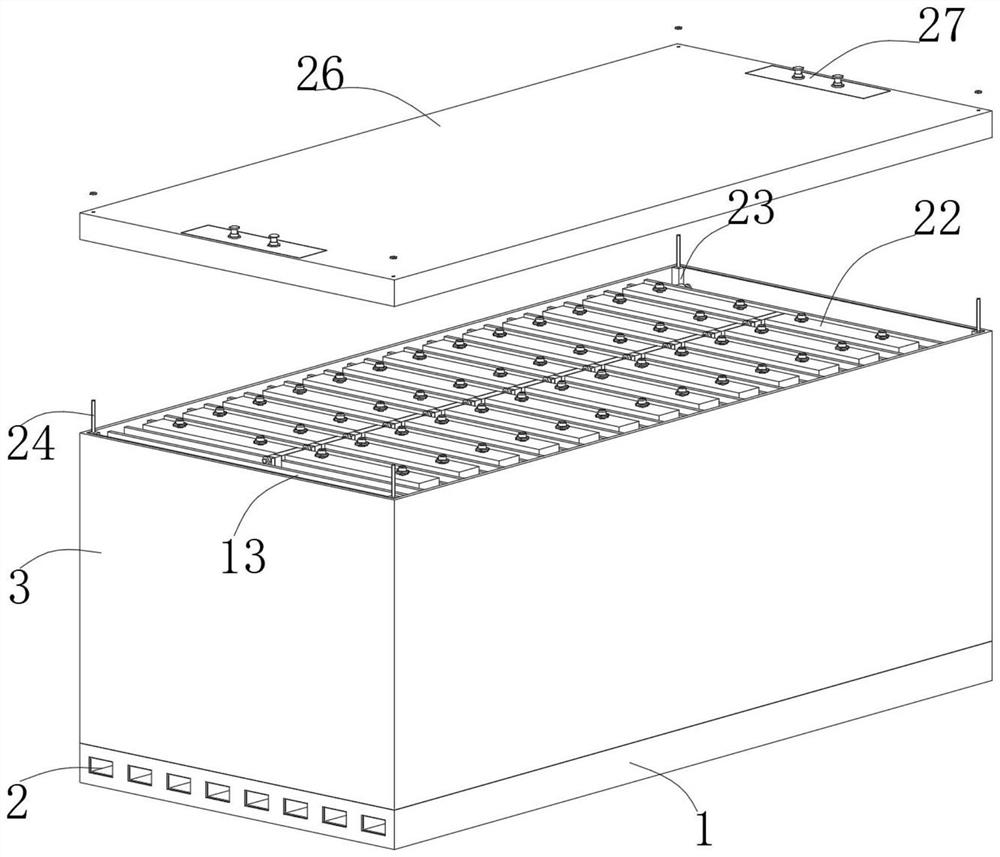

[0028]Embodiment one, with reference to Figure 1-10 : A soft pack cell module with spot welding technology, including a bottom frame 1 and a connecting rod 6, the establishment of the bottom frame 1 provides the installation basis for setting other functional components of the equipment, and at the same time facilitates the installation and setting of the heat dissipation frame 2, and the connecting rod The establishment of 6 facilitates the installation and setting of other functional parts of the equipment. The interior of the bottom frame 1 is equidistantly fixedly connected with multiple heat dissipation frames 2 along the horizontal direction. The establishment of the heat dissipation frame 2 can effectively transfer the heat inside the protective frame 3 to the The protective frame 3 is fixedly connected to the top of the bottom frame 1. The establishment of the protective frame 3 can effectively protect the internal cell body 22 and effectively form a storage space for ...

Embodiment 2

[0029] Embodiment two, refer to Figure 1-5 A plurality of heat dissipation frames 2 are hollow straight quadrangular truss-shaped structures, and the inside of each heat dissipation frame 2 is connected to the outside of the bottom frame 1. This structure can effectively accelerate the flow of air flowing through the heat dissipation frame 2, thereby quickly To dissipate the internal temperature of the protective frame 3, the top of the protective cover 26 is provided with an installation port close to the center of the edges on both sides. , the establishment of the junction block 27 can effectively carry out the output connection of the battery core body 22 inside the protective frame 3, the bottom of each heat conduction block 16 is attached to the top of the heat conduction plate 4, and the outer surface on both sides of each heat conduction block 16 and two elastic limiters The opposite outer surfaces of the strips 5 are attached respectively, the bottom of each cell bod...

Embodiment 3

[0030] Embodiment three, refer to Figure 1-10 : between the outer surfaces of the four connecting threaded rods 24 and the sliding sleeve above the protective frame 3 is provided with a protective cover 26, the establishment of the protective cover 26 enables the inside of the protective frame 3 to form a relatively closed storage space, and effectively prevents the external environment from affecting the protection. The cell body 22 inside the frame 3 causes interference. The outer surface of each connecting threaded rod 24 is located above the protective cover 26 and is threaded with a limit nut. The setting of the limit nut can effectively prevent the protective cover 26 from detaching from the connecting threaded rod 24. The eight support rods 12 are divided into two groups, and each group of four support rods 12 is provided with a buffer plate 13 between the outer surfaces near one end edge. The buffer plate 13 can effectively reduce the impact force of the external envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com