Efficient electromechanical monitoring device for expressway tunnel

A technology for highways and monitoring devices, applied to camera bodies, TVs, cameras, etc., can solve problems such as inconvenient maintenance and dead spots in monitoring, and achieve the effects of avoiding blockage, ensuring stable operation, and promoting flow exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

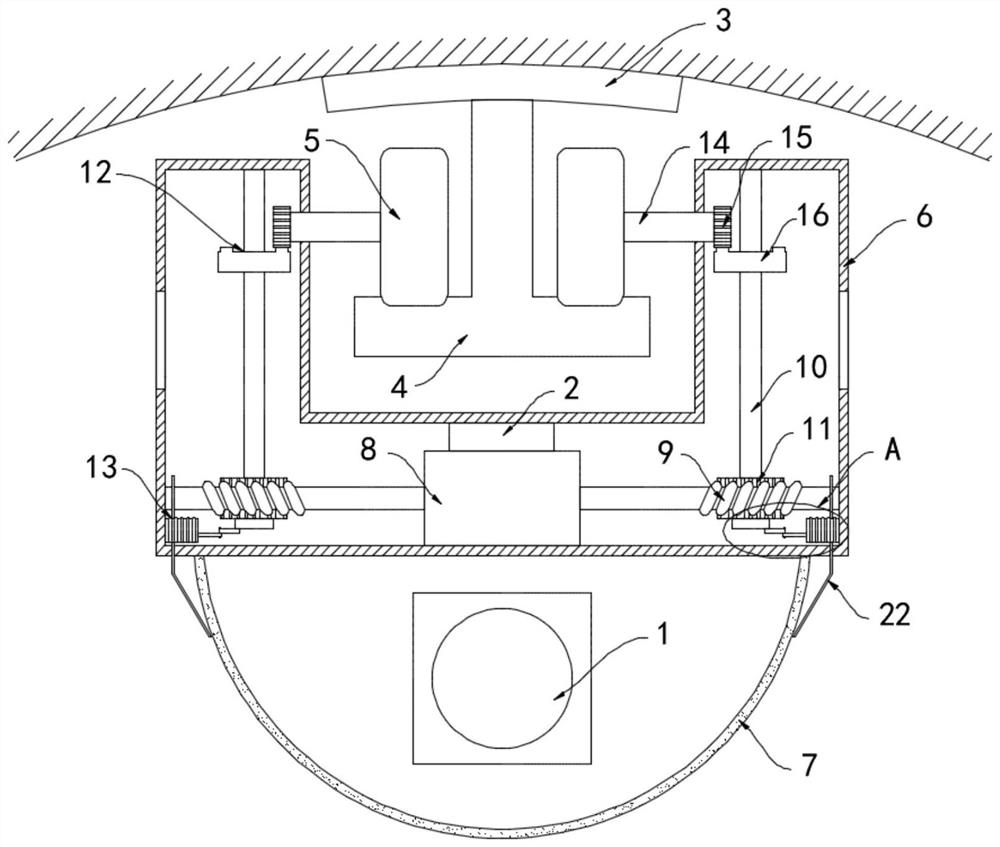

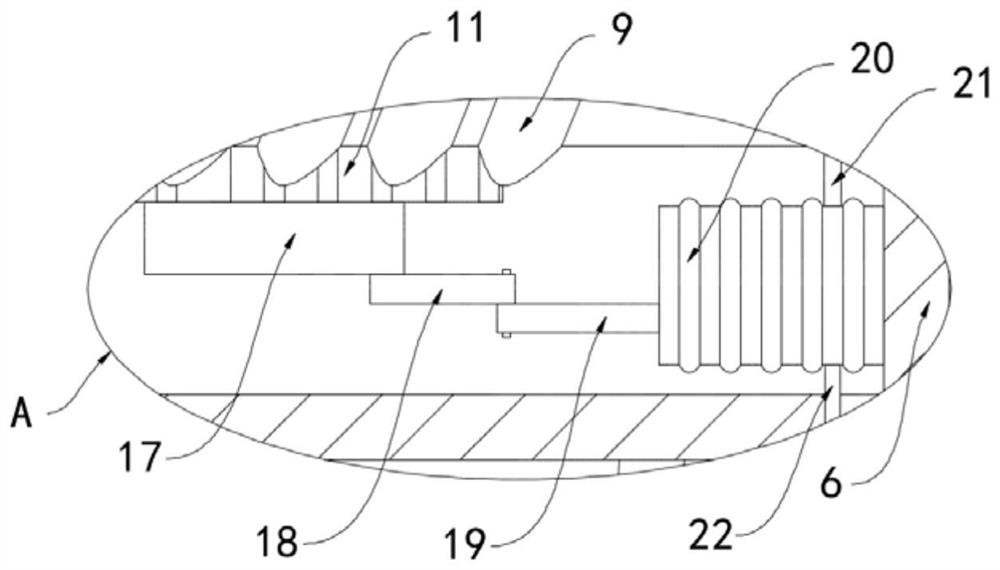

[0023] like Figure 1-2 As shown, a high-efficiency expressway tunnel electromechanical monitoring device includes a camera 1, a central controller 2 and a fixed plate 3. The fixed plate 3 is installed on the top surface of the tunnel and extends longitudinally along the tunnel. The lower surface of the fixed plate 3 is welded with an inverted The T-shaped slide rail 4, the two sides of the T-shaped slide rail 4 are rollingly connected with the traveling wheels 5, the bottom of the T-shaped slide rail 4 is provided with a U-shaped housing 6, and the lower surface of the U-shaped housing 6 is fixedly connected with an anti- Dust cover 7, dust cover 7 is a hemispherical glass cover, is convenient for camera 1 to rotate and shoot at multiple angles in dust cover 7, camera 1 is installed in dust cover 7, and the inner bottom surface of U-shaped housing 6 is equipped with biaxial The motor 8, the camera 1 and the biaxial motor 8 are all electrically connected to the central control...

Embodiment 2

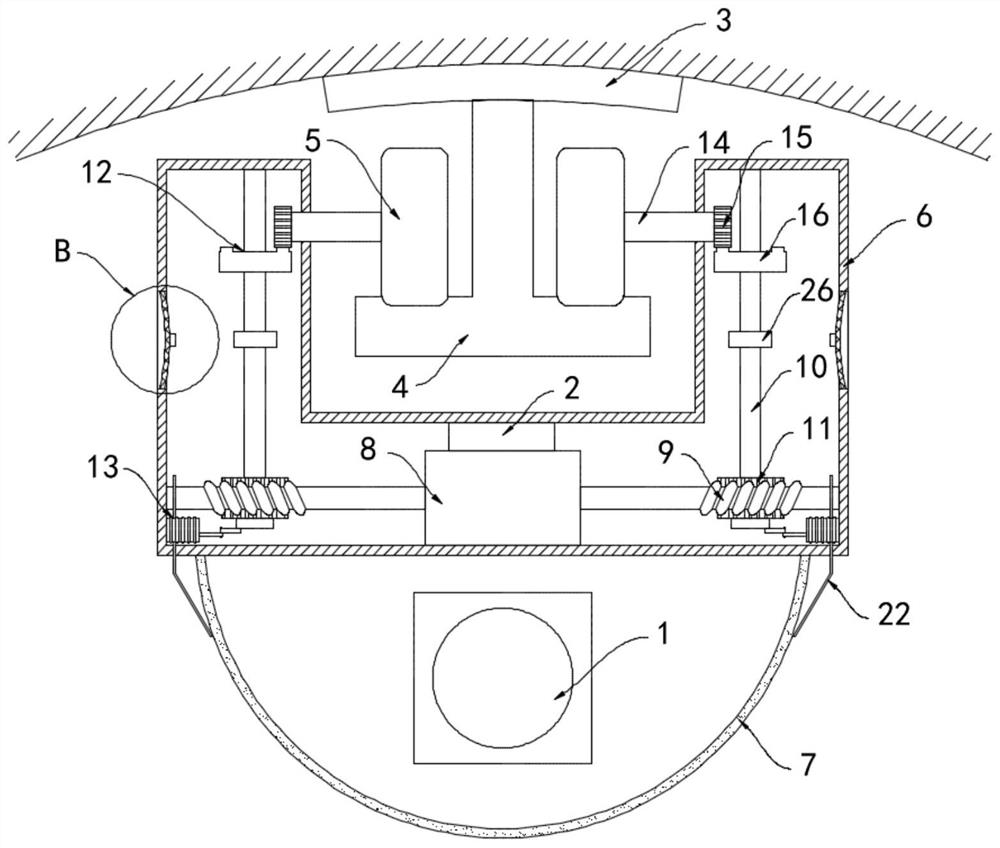

[0029] like Figure 3-4 As shown, the difference between this embodiment and Embodiment 1 is that: the side walls on both sides of the U-shaped housing 6 are provided with an air inlet 23, and a dust filter 24 is installed in the air inlet 23, and the dust filter 24 can be Filter the dust in the air, and the dust filter net 24 is woven by metal wire, has good deformability, is fixedly connected with the magnet block 25 on the side wall of the dust filter net 24, and is fixedly sleeved with the permanent magnetic ring 26 outside the rotating shaft 10, permanent The magnetic ring 26 is made up of two semi-annular magnets with opposite magnetic poles. During the rotation of the permanent magnetic ring 26 with the rotating shaft 10, the two semi-annular magnets with opposite magnetic poles are alternately close to or far away from the magnet block 25, that is, the permanent magnetic ring 26 is periodically The changing attractive and repulsive forces drive the magnet block 25 to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com