A flat-press manufacturing method of biomimetic adhesive structure based on micro-through-hole nickel-based mold

A manufacturing method, hole nickel-based technology, applied in the field of flat-press manufacturing of bionic adhesive structures based on micro-through-hole nickel-based molds, can solve the difficulties of injection molding and demoulding, restrict the formation of complex morphology microstructures, complex physical behavior, etc. problem, to achieve the effect of improving universality, breaking through the bottleneck of imprinting manufacturing technology, and solving high-efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

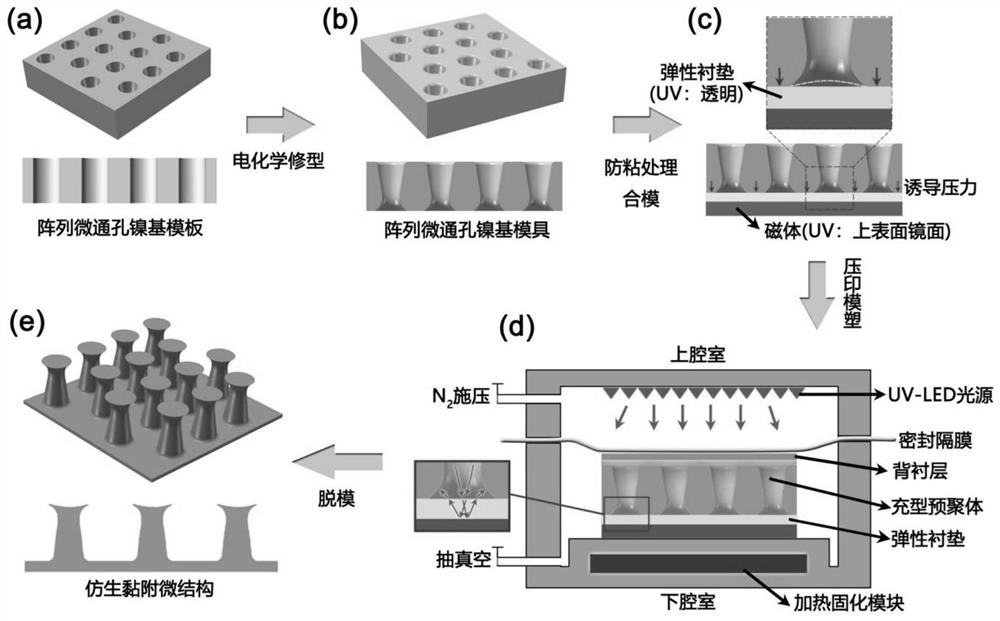

[0040] (1) Preparation of a nickel-based mold with an array of micro-vias

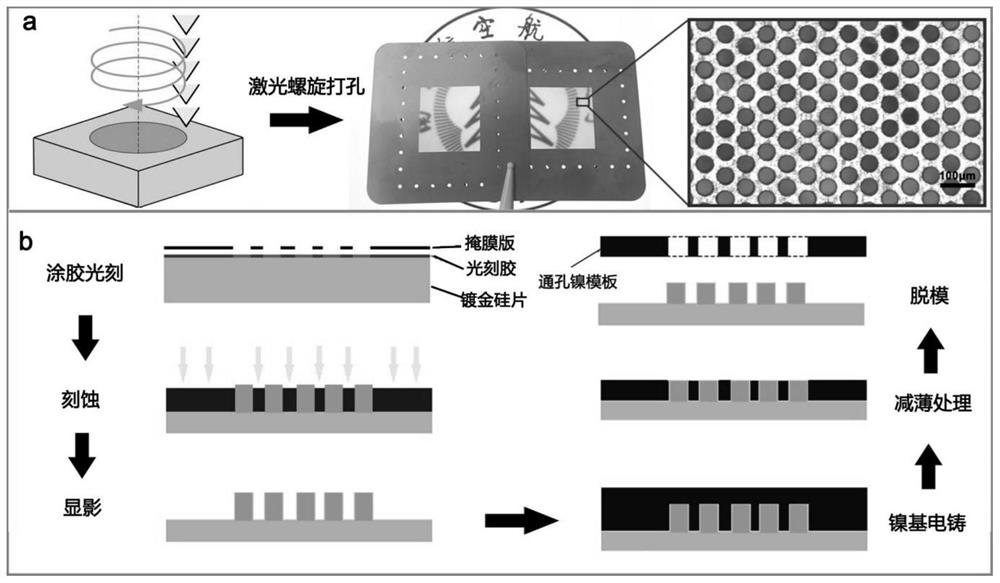

[0041] The processing of high-quality and uniform micro-via arrays on metal substrates can be obtained in two ways, one is the subtractive processing method of femtosecond laser spiral drilling, and the other is silicon-based electroforming Additive manufacturing method, two manufacturing technology options such as figure 2 as shown, figure 2 a A large-scale micro-via nickel-based basic mold was realized by femtosecond laser; figure 2 b shows the combination of photolithography and electroplating manufacturing method, select gold-plated silicon wafer, spin-coat photoresist, expose, develop and clean to realize the processing of micro-column array, combined with electroplating technology, nickel can be obtained after thinning and demolding Base microwell array mold.

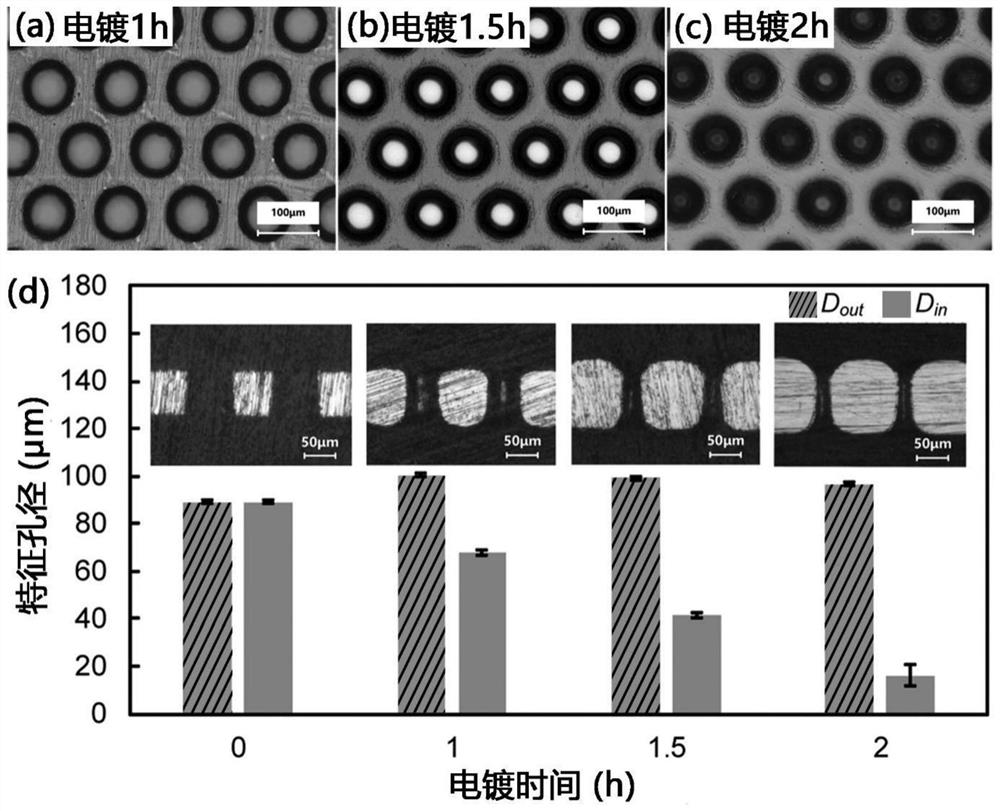

[0042] The electroplating-assisted modification technology of the array micro-via metal mold is the main way to regulate the micro-...

Embodiment 2

[0053] (1) preparation has the nickel base mold of micro-hole array, and specific content is with embodiment 1;

[0054] The through holes of the nickel-based mold of the prepared micro-through-hole array are trumpet-shaped holes, the largest hole diameter is 50 μm, the thickness of the nickel-based mold is 100 μm, and the hole density is > 10,000 / cm 2 , Anti-adhesive treatment is carried out on the nickel-based mold with micro-through-hole array, and the anti-adhesive treatment method is oxygen plasma treatment and surface fluorination.

[0055] (2) Put the nickel base mold on the elastic liner in the magnetic clamping system;

[0056] Put the nickel-based mold obtained in the previous step on the elastic pad in the magnetic mold clamping system. The main body of the magnet in the magnetic mold clamping system is a NdFeB permanent magnet with an electroplated layer on the outer surface. The upper surface roughness Ra≤0.05μm, The surface finish is greater than grade 10, and t...

Embodiment 3

[0062] (1) preparation has the nickel base mold of micro-hole array, and specific content is with embodiment 1;

[0063] The through holes of the nickel-based mold of the prepared micro-via array are wedge-shaped holes, the largest hole diameter is 90 μm, the thickness of the nickel-based mold is 300 μm, and the hole density is >10,000 / cm 2 , Anti-adhesive treatment is carried out on the nickel-based mold with micro-through-hole array, and the anti-adhesive treatment method is oxygen plasma treatment and surface fluorination.

[0064] (2) Put the nickel base mold on the elastic liner in the magnetic clamping system;

[0065] Put the nickel-based mold obtained in the previous step on the elastic liner in the magnetic mold clamping system. The main body of the magnet in the magnetic force mold clamping system is an electromagnet. The elastic liner is a polyurethane elastic liner with an elastic modulus of 5MPa and a thickness of 5mm. .

[0066] (3) Imprint filling and curing p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com