Tire parameter optimization method based on improvement of road noise performance of whole vehicle

An optimization method and tire technology, applied in tire parts, vehicle parts, special data processing applications, etc., can solve problems such as failure to establish contact with tire road noise response, reduce the number of rounds and vehicle road tests, reduce The effect of low R&D costs and engineering experience requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples.

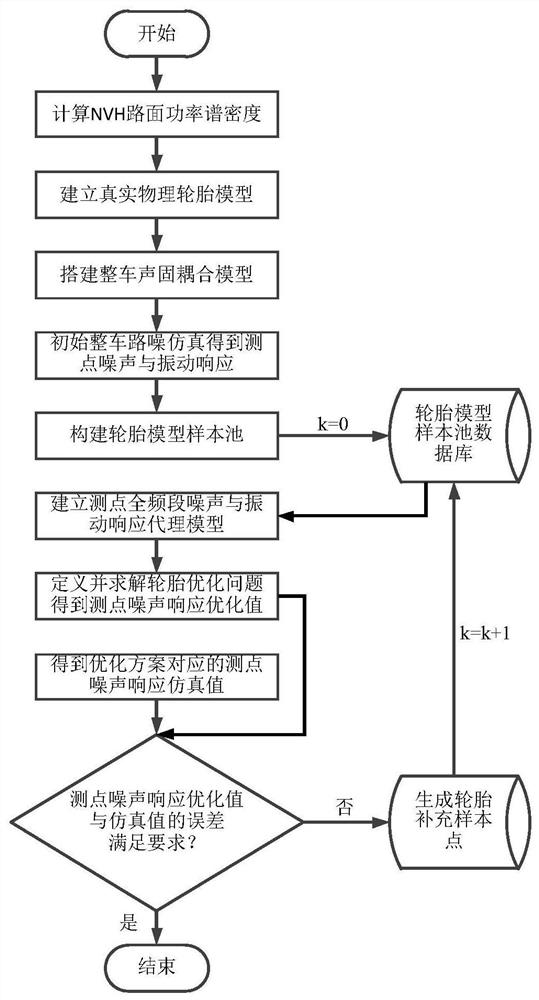

[0032] like figure 1 As shown in , the tire parameter optimization method based on vehicle road noise performance improvement includes the following steps:

[0033] A. Calculate NVH road surface power spectral density;

[0034] B. Establish a real physical tire model;

[0035] C. Build the vehicle-acoustic-solid coupling model;

[0036] D. Obtain the vehicle noise and vibration response under the initial design scheme of the tire based on the simulation of the real physical tire model;

[0037] E. Construct a tire model sample pool by parameter combination;

[0038] F. Construct the display mathematical relationship between the key physical parameters of the tire and the full-freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com