Detachable U-shaped tube bundle tail anti-vibration structure

A technology of anti-vibration structure and U-shaped tube, which is applied in the direction of lighting and heating equipment, heat exchange equipment, heat exchanger shell, etc., can solve the problems of factory economic loss, difficult to expose the end face of the tube sheet, and heat exchanger failure, etc., to achieve Save manufacturing cost, reduce welding workload, and avoid the effect of inconvenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

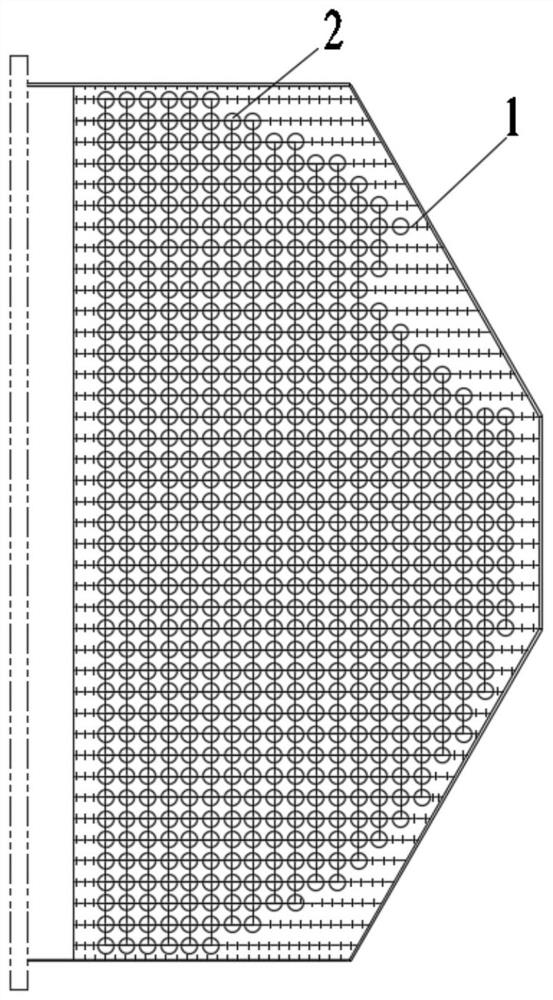

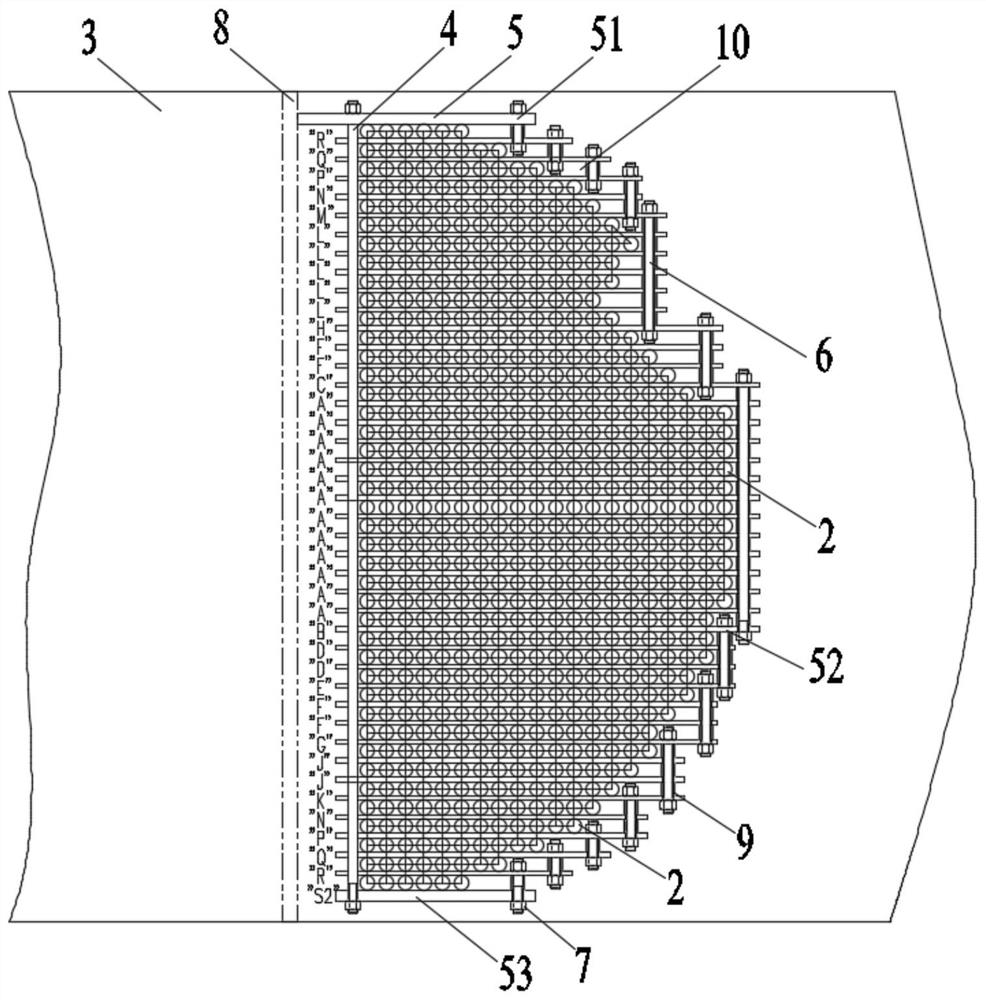

[0014] Such as figure 2 As shown, the present invention is a detachable U-shaped tube bundle tail vibration-proof structure, which includes a support tube 4 vertically arranged in the shell-side cylinder 3, and the support tube 4 is located in the U-shaped tube bundle in the shell-side cylinder 3 At the center position of the tail part 10, it also includes a number of flat steel bars 5 and tie rods 6. The lengths of the flat steel bars 5 and tie rods 6 are different, depending on the assembly conditions. Flat steel bars 5 are arranged between the heat exchange tubes 2, and the support tube 4 runs through one end of all the flat steel bars 5 from top to bottom and is locked by nuts 7, and is located at one end of the U-shaped tube bundle tail 10. One end of the flat steel bar 5 is connected with the last baffle 8 arranged in the shell side cylinder 3, and the other ends of the upper and lower adjacent flat steel bars 5 are connected by a tie rod 6, and then connected by a nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com