Straight pipe and clamp ring matching structure for swimming pool pump

A matching structure and clasp technology, applied in the direction of pipe supports, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of high cost, time-consuming and laborious, and inability to disassemble the pipe, so as to ensure firmness and enhance the strength of the circumferential surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

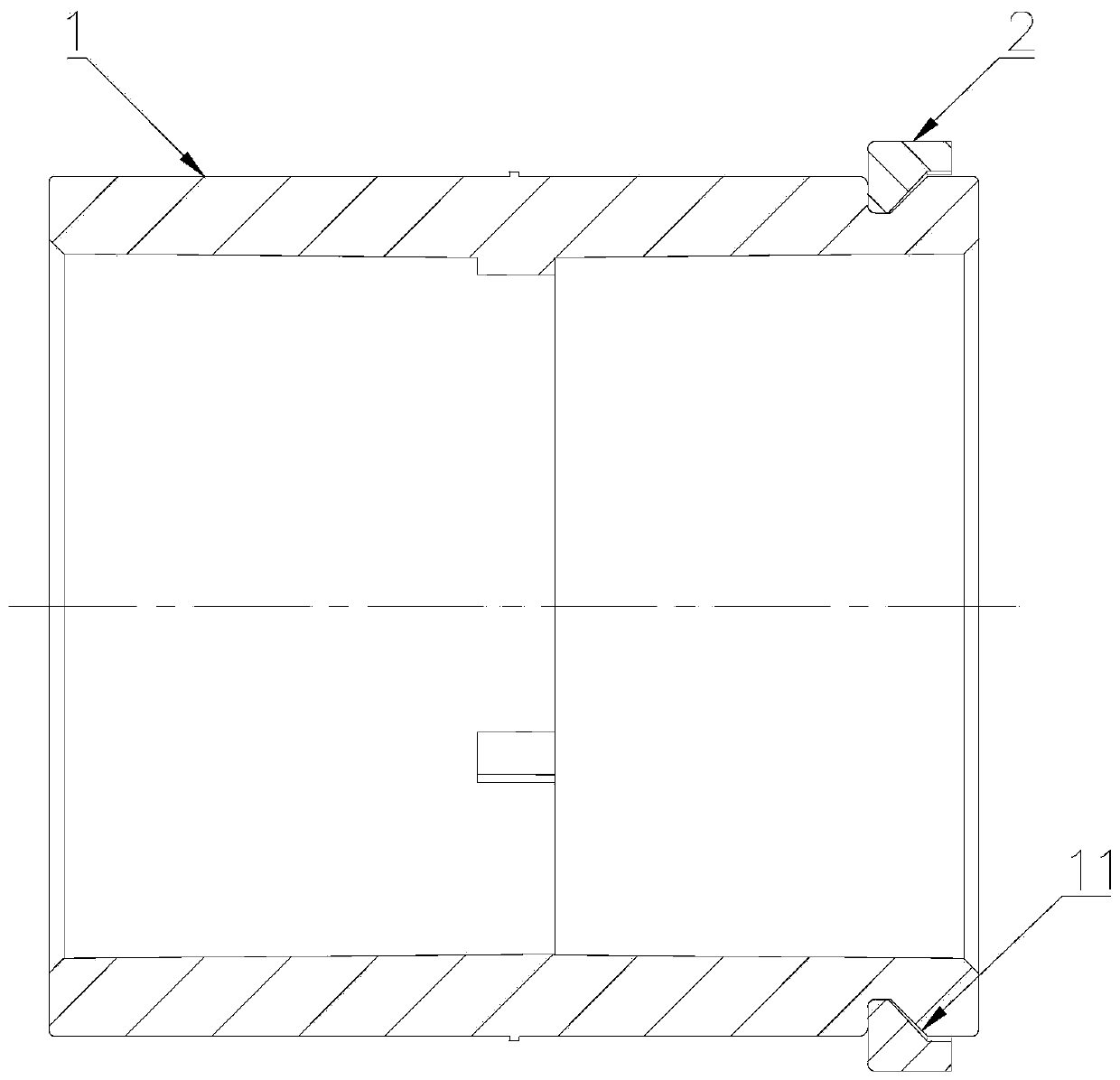

[0035] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is: a straight pipe clasp fitting structure for a swimming pool pump, including a pipe main body and a clasp main body;

[0036] The main body of the pipe is cylindrical, the inside of the main body of the pipe is hollow and a through hole is opened in the axial direction, the outer wall of the main body of the pipe near the opening end is provided with an annular groove, the cross-sectional shape of the annular groove is a right-angled trapezoid, The hypotenuse of the right-angled trapezoid is located on the side of the annular groove close to the open end;

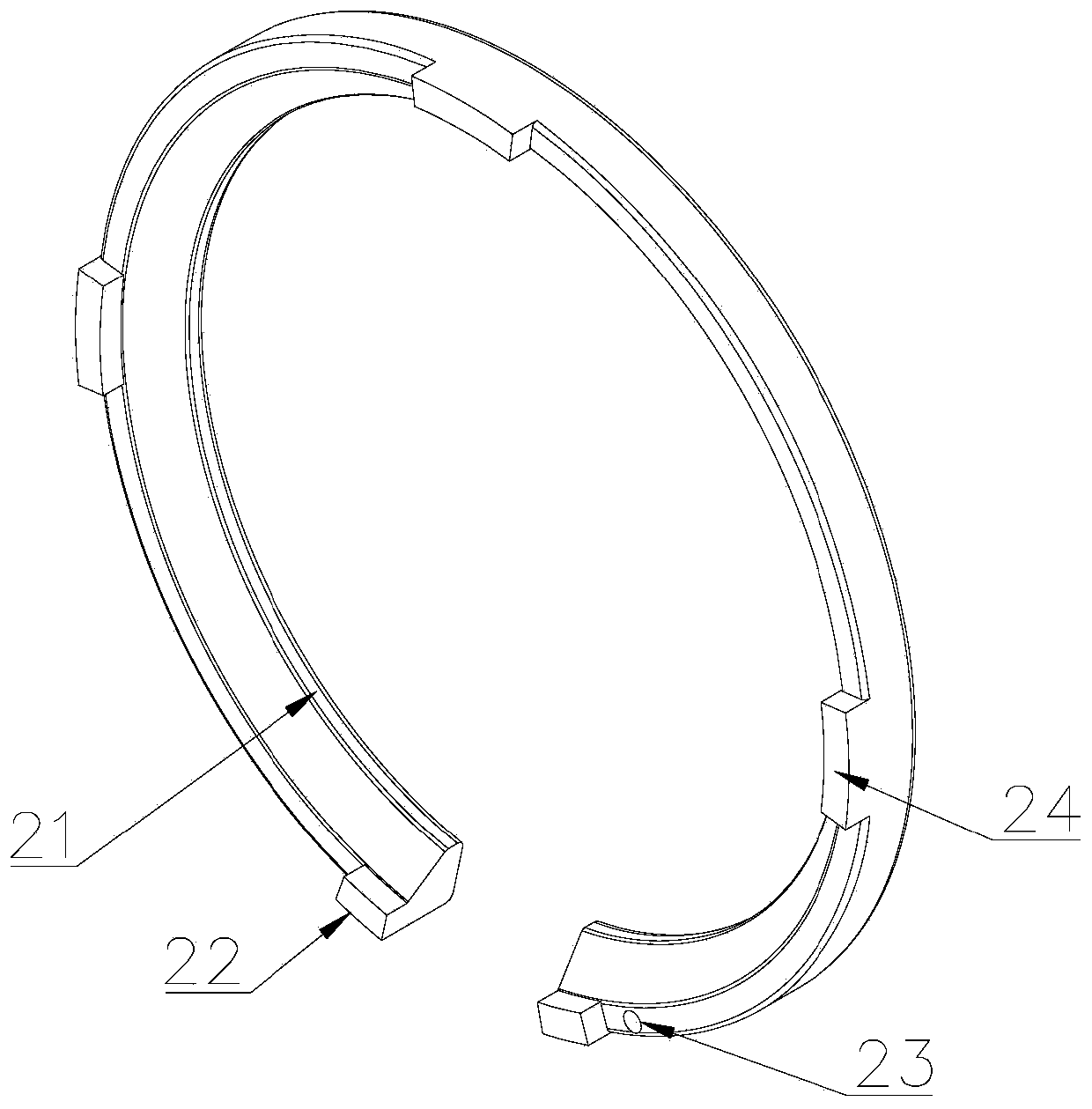

[0037] The main body of the snap ring has a ring structure, the main body of the snap ring has a fracture, and the inner wall of the main body of the snap ring is provided with an annular boss whose shape matches the annular groove.

Embodiment 2

[0038] Please refer to Figure 1 to Figure 2 , the second embodiment of the present invention is: a straight pipe clasp fitting structure for a swimming pool pump, including a pipe main body and a clasp main body;

[0039] The main body of the pipe is cylindrical, the inside of the main body of the pipe is hollow and a through hole is opened in the axial direction, the outer wall of the main body of the pipe near the opening end is provided with an annular groove, the cross-sectional shape of the annular groove is a right-angled trapezoid, The hypotenuse of the right-angled trapezoid is located on the side of the annular groove close to the open end;

[0040] The main body of the snap ring has a ring structure, the main body of the snap ring has a fracture, and the inner wall of the main body of the snap ring is provided with an annular boss whose shape matches the annular groove.

[0041] The snap ring main body is provided with fixing bosses on the end surface facing the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com