A telescopic test probe with integrated calibration device

A kind of calibration device, telescopic technology, applied in the direction of measuring device, measuring device shell, measuring circuit, etc., can solve the problems of uneven force, probe damage, difficult handling, and damaged probe, so as to achieve convenient operation, improve test efficiency, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

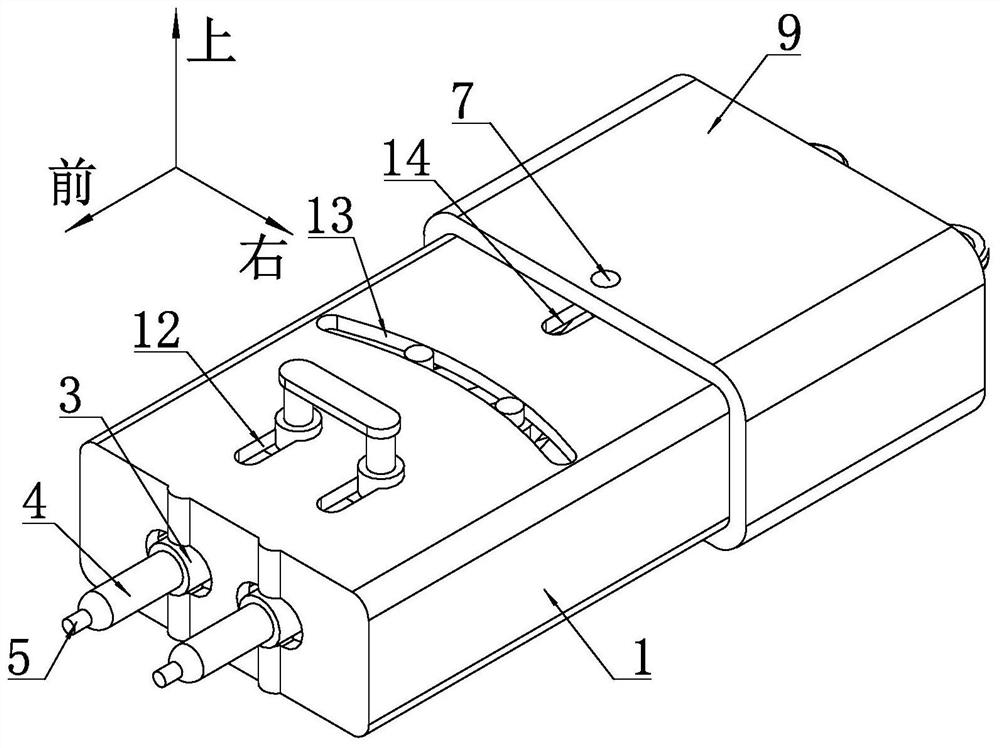

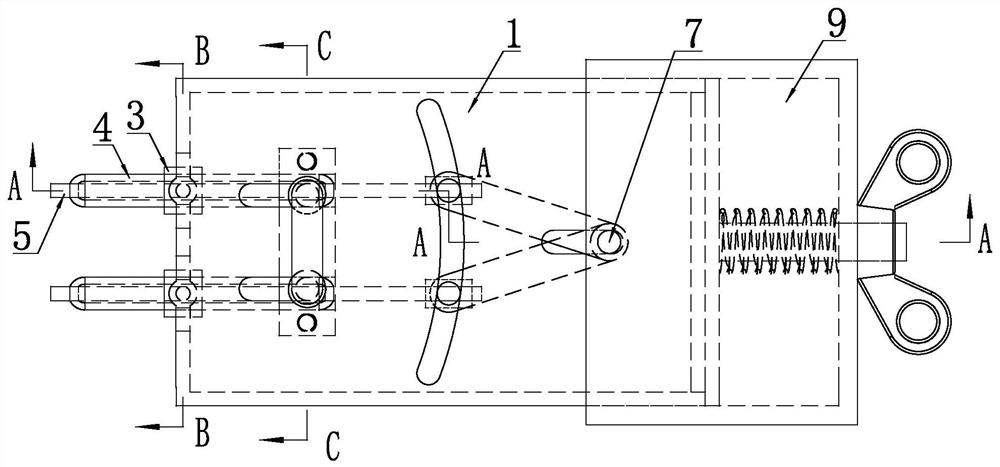

[0046] For the convenience of description, the coordinate system is now defined as figure 1 As shown, the left-right direction is the horizontal direction, the front-rear direction is the vertical direction, and the up-down direction is the vertical direction.

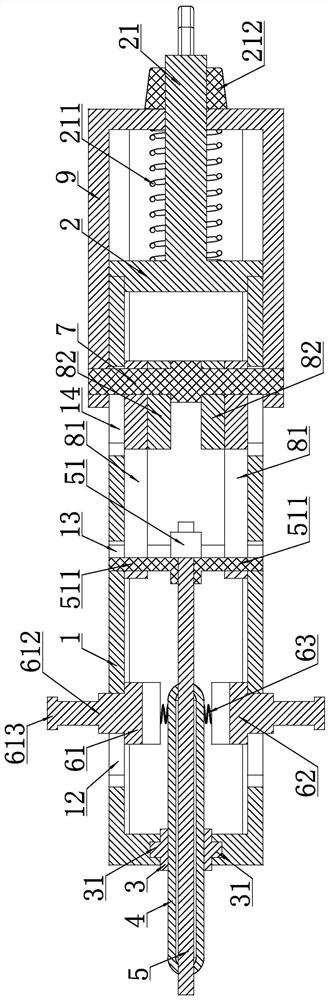

[0047] like figure 1 and Image 6 As shown, a telescopic test probe with an integrated calibration device includes a main casing 1, the section of the main casing 1 is a square structure, and the whole is a cylindrical structure with a front end closed and a rear end opening. The rear end of the main casing 1 is provided with a sealing plate 2 for closing the main casing 1 .

[0048] like Figure 7 As shown, the front end (that is, the closed end) of the main casing 1 is provided with two avoidance holes 11 penetrating the front side wall of the main casing 1 in the front-rear direction, and the two avoidance holes 11 are related to the The vertical symmetry planes of the main casing 1 are arranged symmetrically. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com