Perovskite light-emitting film layer and preparation method thereof, and display panel

A technology of perovskite and light-emitting film, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as poor patterning effect of light-emitting layer, and achieve the effect of precise patterning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

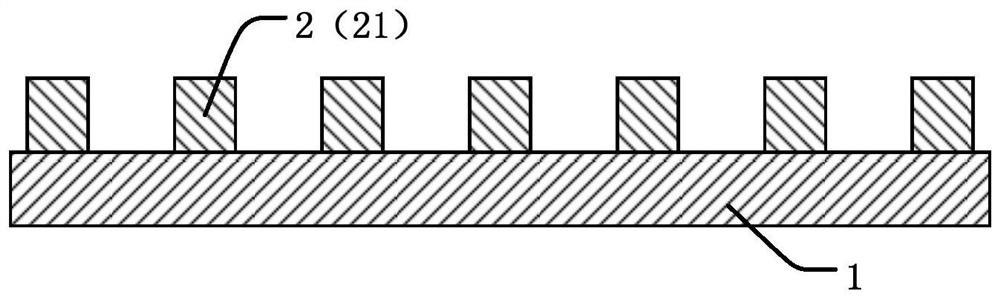

[0035] like figure 1 As shown, an embodiment of the present invention provides a display panel, including: a substrate 1 and a perovskite light-emitting film layer 2 .

[0036] The substrate 1 may be an array substrate, which functions to control circuit switches in the display panel, which will not be described in detail here.

[0037] The perovskite light-emitting film layer 2 is arranged on the upper surface of the substrate 1, and the perovskite light-emitting film layer 2 plays a role of emitting light. The material of the perovskite light-emitting film layer 2 is mainly perovskite, and the perovskite includes zero Any one of dimensional perovskite (0D), one-dimensional perovskite (1D), two-dimensional perovskite (2D), quasi-two-dimensional perovskite (2D), and three-dimensional perovskite (3D).

[0038] The perovskite light-emitting film layer 2 includes a perovskite light-emitting base layer 21. The perovskite light-emitting base layer 21 has a plurality of patterned l...

Embodiment 2

[0053] like Image 6 As shown, this embodiment provides a display panel, which specifically includes: a substrate 1 and a perovskite light-emitting film layer 2 .

[0054] The substrate 1 may be an array substrate, which functions to control circuit switches in the display panel, which will not be described in detail here.

[0055] The perovskite light-emitting film layer 2 is disposed on the upper surface of the substrate 1 . The perovskite light-emitting film layer 2 plays a role of emitting light. The perovskite light-emitting film layer 2 includes a perovskite light-emitting base layer 21 and a light-shielding structure 23 .

[0056] The material of the perovskite light-emitting base layer 21 is mainly perovskite, and the perovskite includes zero-dimensional perovskite (0D), one-dimensional perovskite (1D), two-dimensional perovskite (2D), and quasi-two-dimensional perovskite. Any of perovskite (2D) and three-dimensional perovskite (3D) minerals.

[0057] The light-shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com