Method for recovering energy from the combustion engine during changing up, and control device for carrying out the method

A control device, a technology for an internal combustion engine, applied in the field of recovering the energy of the internal combustion engine during upshifting and for implementing the control device, capable of solving problems such as poor exhaust gas values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

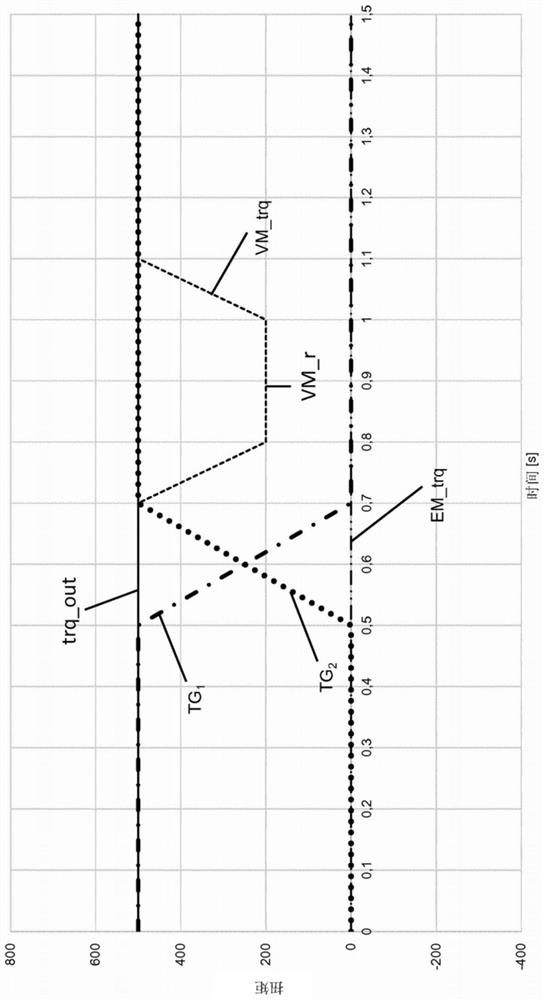

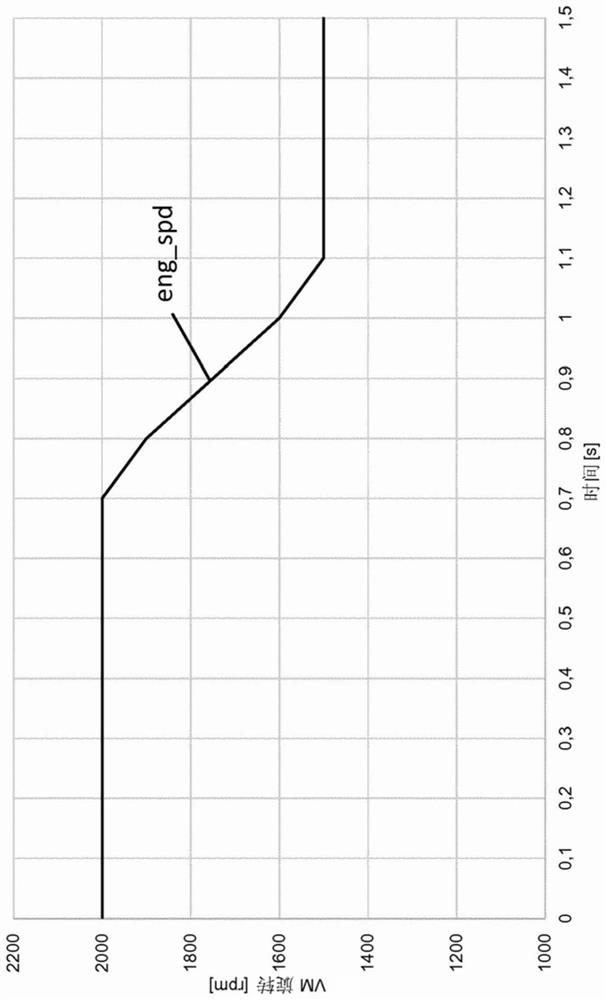

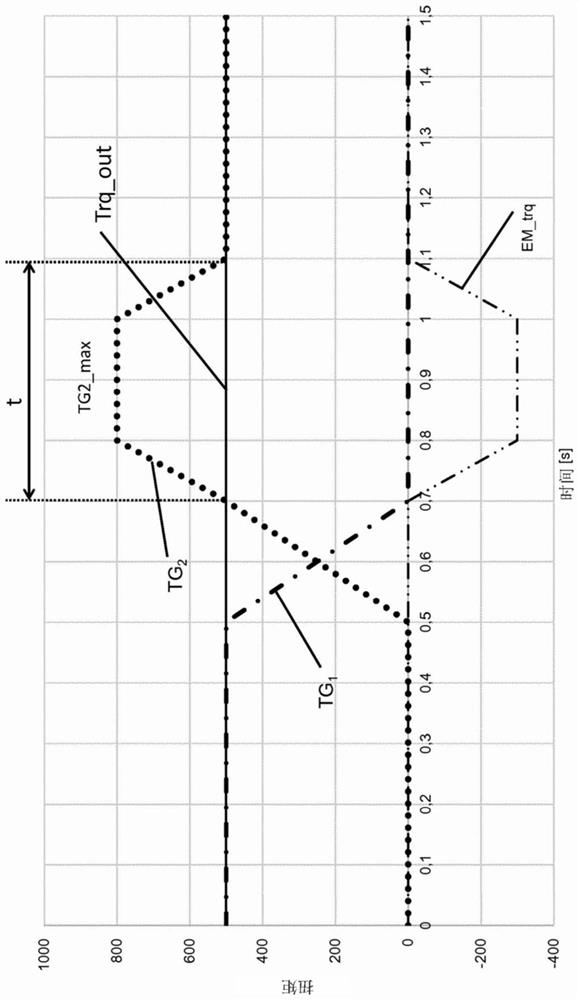

[0024] in Figure 4 Schematically shows an integrated hybrid technology solution with an electric motor EM in a dual-clutch transmission. As an additional electric machine, the system has a starter generator 13.

[0025] The technical solution according to the present invention can be implemented not only as a hybrid dual-clutch transmission, but also as a starter generator.

[0026] The power train 10 includes an internal combustion engine (VM) VM, which is connected to a starter generator 13. In addition, the power train 10 includes a dual-clutch transmission 14 whose output side is connected to a differential 16. The differential 16 distributes the driving power to the left and right driving wheels 18L, 18R.

[0027] The dual clutch transmission 14 includes a first friction clutch 30 and a first sub-transmission TG 1 . First sub-transmission TG 1 For example, it includes gears N, 1, 3, 5, etc., which can be engaged and disengaged by means of a schematically shown shift clutch 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com