Window frame splicing table

A technology for window frames and countertops, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low safety, low production output, and low degree of automation, and achieve stable and reliable installation and stable and reliable turning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

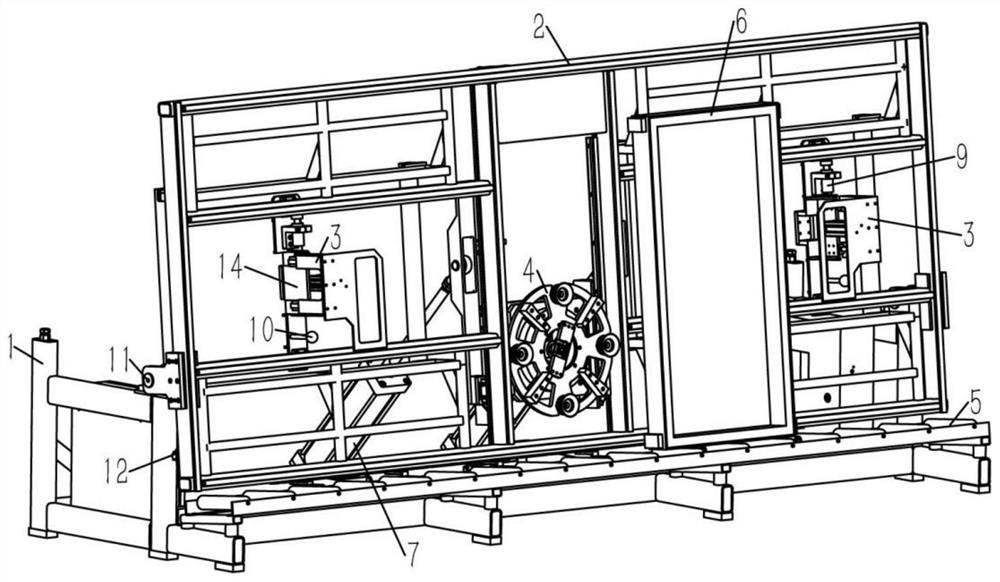

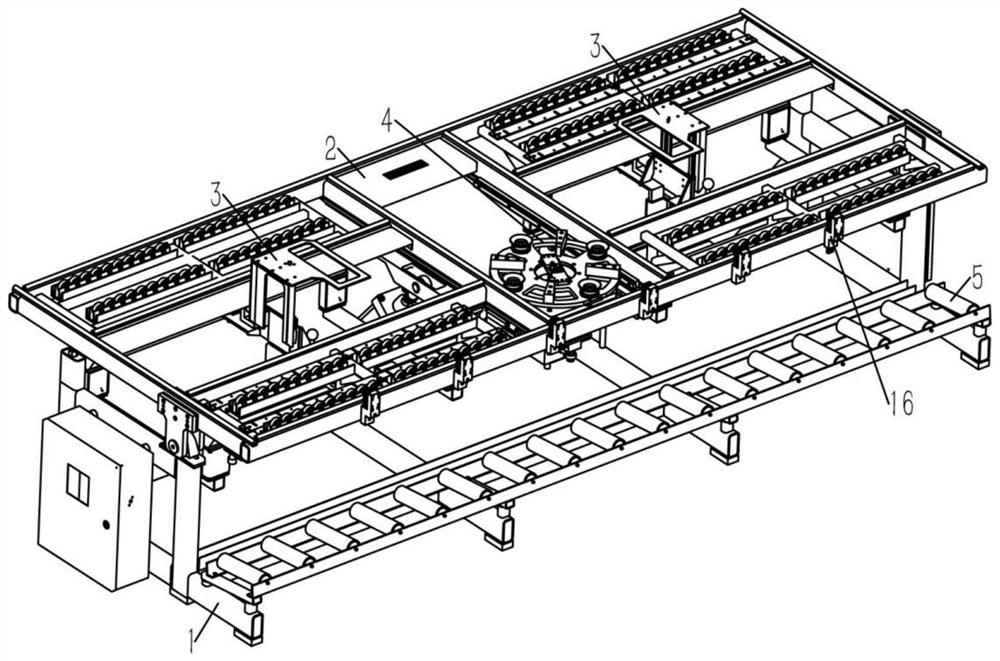

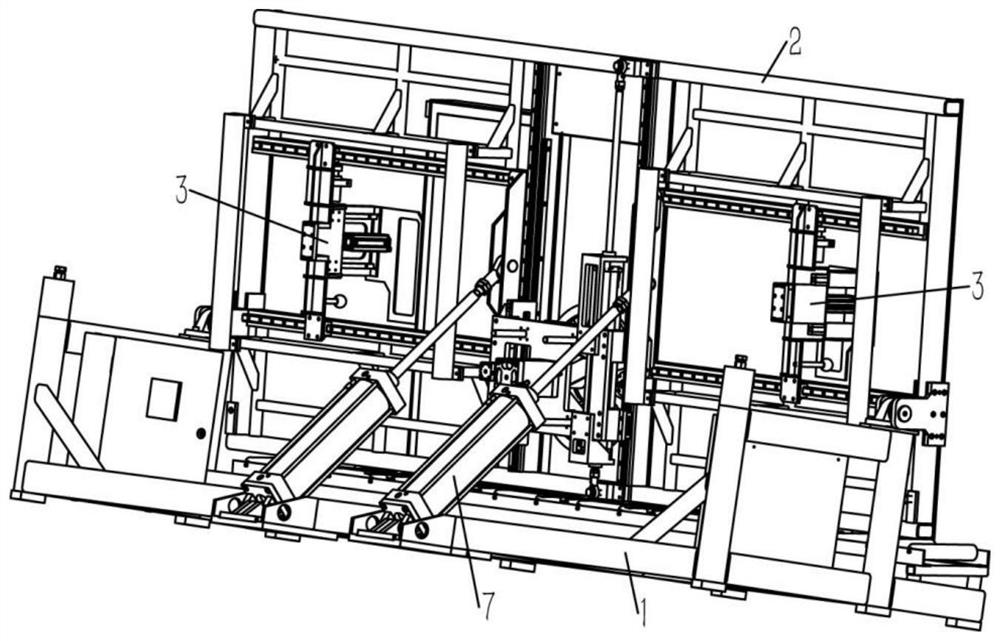

[0018] Such as Figures 1 to 3 As shown, a window frame splicing platform includes a base 1 and a table 2 hinged on the base 1. A turning mechanism is provided between the table 2 and the base 1 to turn the table 2. The turning mechanism can put the table 2 in a horizontal loading state. To turn over between the inclined blanking state, the base 1 is also provided with a raceway 5, when the table 2 is in the blanking state, the lower edge of the table 2 is close to the raceway 5, and the table 2 is provided with an adsorption table 4, which can be opposite to the table 2 Lifting, sliding, rotating, and capable of absorbing glass, the surface of the adsorption table 4 is higher than the table 2 when it rises, and is flush with the table 2 when it falls, and the table 2 is also equipped with a pressing component 3, which slides on the table 2 Connected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com